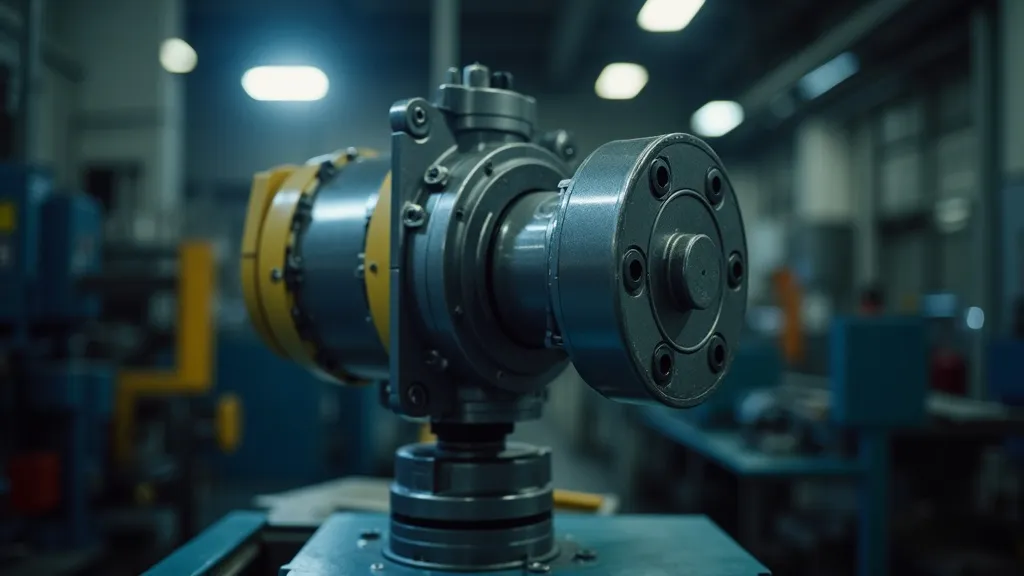

Parker Pneumatic Actuators are critical components in automation, offering precise control in various industrial applications. These devices convert energy into mechanical motion, facilitating the automation of tasks across different sectors. Their efficiency and reliability make them indispensable in modern industrial operations.

Parker Pneumatic Actuators are vital in the realm of industrial automation, where precision and reliability are paramount. These actuators convert compressed air into mechanical motion, which is crucial for automating processes in industries ranging from manufacturing to aerospace. Their design and functionality allow for seamless integration into complex systems, enhancing operational efficiency and reducing manual labor requirements. As industries strive for higher productivity and lower operational costs, the adoption of pneumatic actuators like those from Parker becomes increasingly relevant. The ability to automate repetitive tasks without the need for electricity not only reduces costs but also minimizes downtime while improving overall safety in the workplace.

Parker Pneumatic Actuators stand out for their robust construction and high performance. They are designed to operate under extreme conditions, making them suitable for a wide range of applications. The key benefits include:

The versatility of Parker Pneumatic Actuators allows them to be used across multiple industries. In the automotive sector, they automate assembly lines, improving speed and precision. For instance, they might be employed in robotic arms that assemble components, reducing human error and increasing throughput. In the food and beverage industry, they ensure the hygienic and efficient handling of products, such as in automated packaging systems that require swift and accurate movements without contaminating food products.

Aerospace applications benefit from their ability to function under extreme conditions, contributing to the reliability and safety of aircraft systems. For example, pneumatic actuators are often used in flaps and landing gear mechanisms, where weight reduction is critical, and the control over movement must be precise to ensure safety during flight. In addition, Parker Pneumatic Actuators are utilized in the pharmaceutical industry, where they help automate processes such as the filling, capping, and labeling of bottles, ensuring compliance with strict hygiene standards.

Moreover, in the construction and mining sectors, pneumatic actuators are employed in machinery that requires robust performance in rugged environments. They are used in drilling rigs and other heavy machinery that operate under high pressure and in challenging conditions, showcasing their adaptability and durability across different industries.

| Actuator Type | Advantages | Disadvantages |

|---|---|---|

| Pneumatic | High speed, cost-effective, simple design | Requires a compressed air system, less precise than electric actuators |

| Electric | Precise control, easy integration with digital systems, no need for compressed air | Higher initial cost, complex maintenance, potential for overheating |

| Hydraulic | High force output, suitable for heavy-duty applications, good at maintaining position under load | Complex system, potential for leaks, requires maintenance for fluid levels |

When evaluating actuator types, it’s essential to consider the specific application requirements. Pneumatic actuators excel in environments where speed and lower costs are priorities, making them a popular choice for applications where rapid cycling is vital. Electric actuators, on the other hand, are more suited for applications that require fine control and precise positioning, such as in robotics or CNC machinery. Hydraulic actuators are typically reserved for applications requiring significant force, such as heavy lifting or pressing tasks, but with their complexity and maintenance needs, they don't fit every scenario.

Parker Pneumatic Actuators represent a cornerstone of industrial automation, providing an effective solution for a diverse range of applications. Their reliability, efficiency, and precision make them indispensable in various sectors, from automotive manufacturing to aerospace engineering. As industries continue to evolve, the demand for high-performance actuators will likely increase, and Parker is well-positioned to meet this demand through innovation and commitment to quality.

As technology advances, the landscape of pneumatic actuator design and application is continuously changing. Here are some notable trends that are shaping the future of pneumatic actuators:

The future of pneumatic actuators, particularly those offered by Parker, is bright as industries continue to embrace automation and the need for efficiency and reliability. By staying at the forefront of technology and innovation, Parker Pneumatic Actuators are poised to play a crucial role in the evolution of industrial automation. As businesses seek to improve productivity and reduce costs, pneumatic actuators will remain a fundamental component in achieving these goals while ensuring high standards of safety and performance.

In conclusion, Parker Pneumatic Actuators not only represent a significant advancement in automation technology but also highlight the necessity of reliable and efficient systems in today's fast-paced industrial landscape. As we look ahead, the ongoing development in actuator technology will undoubtedly open up new possibilities and applications, further solidifying the importance of pneumatic actuators in the future of industrial operations.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!