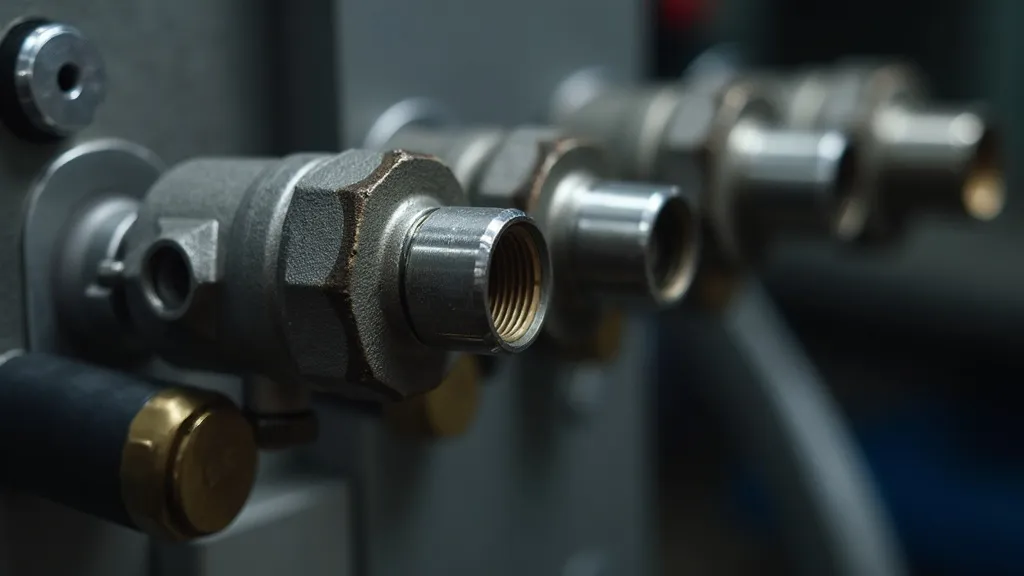

Pneumatic fittings are essential components in pneumatic systems, designed to connect sections of pipe, tube, and hose. These fittings are crucial for maintaining the direction and flow of air within these systems, ensuring efficient operation and safety. This article delves into the types, applications, and selection criteria of pneumatic fittings, offering insights into their role in modern industrial settings.

Pneumatic fittings play a vital role in the functionality of pneumatic systems, which are widely used in various industries for automation, manufacturing, and transportation. These fittings are designed to connect sections of pipe, tube, and hose, ensuring the efficient and safe transfer of air or gas. Understanding the types and applications of pneumatic fittings is crucial for professionals seeking to optimize their industrial systems. The importance of pneumatic fittings cannot be overstated, as they not only contribute to the performance of the system but also impact the overall safety and reliability of pneumatic operations.

In recent years, the demand for pneumatic systems has surged, driven by advancements in technology and increased automation in manufacturing and production processes. This heightened interest has placed a spotlight on pneumatic fittings, compelling manufacturers to innovate and improve designs to meet evolving industry standards and customer expectations. Consequently, professionals in the field are increasingly required to have a comprehensive understanding of pneumatic fittings to make informed decisions about their use in various applications.

Pneumatic fittings are available in a variety of types, each serving specific functions within a pneumatic system. Common types include push-to-connect fittings, compression fittings, barbed fittings, and others such as threaded fittings and quick disconnect fittings. Each type of fitting is engineered to fulfill particular requirements and conditions, making it essential to choose the appropriate fitting for specific applications.

Push-to-connect fittings are popular for their ease of use, allowing quick and secure connections without the need for tools. They are widely employed in applications where frequent disconnection and reconnection are necessary, as users can easily attach or detach hoses and tubes with minimal effort. These fittings are often made from durable materials that can withstand the rigors of various industrial environments.

Compression fittings provide a tight seal and are ideal for high-pressure applications. They work by compressing a ring onto the pipe or tube, ensuring a leak-proof connection that can handle significant pressure fluctuations. Compression fittings are commonly used in systems where reliability is paramount, such as in hydraulic applications and pneumatic systems that operate under high pressure.

Barbed fittings, on the other hand, are used for flexible hoses and offer a reliable connection through their serrated design. The barbs grip the inner wall of the hose, creating a strong bond that prevents disconnection under pressure. These fittings are particularly useful in applications where the hose is subject to movement or vibration, as they provide a secure attachment that can withstand such stress.

Threaded fittings are another commonly used type. They feature male and female threads that allow for secure connections between different components of a pneumatic system. Quick disconnect fittings are designed for applications where tools are not readily available, enabling users to detach components quickly and efficiently. Each of these fittings has its own unique benefits and is suited for various applications, making it essential for professionals to understand their characteristics and uses.

Pneumatic fittings are employed in a wide range of applications across industries such as automotive, aerospace, manufacturing, and healthcare. In the automotive industry, they are used in air suspension systems, braking systems, and pneumatic doors. Air suspension systems utilize pneumatic fittings to control ride height and provide a smoother driving experience, while braking systems rely on pneumatic technology to enhance safety and performance.

The aerospace sector utilizes pneumatic fittings for controlling cabin pressure, operating landing gear, and in various other systems that require precise control. The ability to maintain cabin pressure at high altitudes is critical for passenger comfort and safety, and pneumatic fittings are integral to these systems. Additionally, pneumatic actuators powered by compressed air are used to operate landing gear during takeoff and landing, showcasing the importance of reliable fittings in aviation.

In manufacturing, pneumatic fittings are integral to automation systems, enabling precise control of machinery and processes. They are used in assembly lines, packaging machines, and robotic systems to facilitate efficient operation and enhance productivity. The use of pneumatic systems in manufacturing has grown significantly due to their ability to provide consistent and reliable performance, making pneumatic fittings essential for maintaining optimal operations.

The healthcare industry relies on pneumatic systems for devices such as ventilators, surgical instruments, and medical gas delivery systems. Pneumatic fittings are crucial in ensuring the safe and effective transfer of gases used in medical procedures. For instance, ventilators utilize pneumatic technology to assist patients in breathing, highlighting the importance of high-quality fittings that can maintain pressure and flow rates required for patient care.

Choosing the right pneumatic fitting is crucial for the efficiency and safety of a system. Key factors to consider include the material of the fitting, the type of connection, the pressure and temperature ratings, and the compatibility with the fluid or gas in use. Materials such as brass, stainless steel, and plastic are commonly used, each offering distinct advantages.

Brass fittings are durable and corrosion-resistant, making them suitable for a wide range of applications, including those involving moisture or chemicals. Their strength and reliability make them a popular choice in many industrial settings. Stainless steel fittings provide strength and high-temperature resistance, making them ideal for applications that require durability under extreme conditions. They are often used in environments where cleanliness and resistance to corrosion are essential, such as in the food processing and pharmaceutical industries.

Plastic fittings are lightweight and cost-effective, making them an appealing option for less demanding applications. They are resistant to corrosion and can be used in various environments, but care must be taken to ensure that they are compatible with the specific gases or fluids they will be exposed to. Additionally, the pressure ratings of plastic fittings may not be as high as those of metal fittings, so understanding the operational requirements is critical when selecting materials.

Another important consideration is the connection type. Pneumatic fittings may require specific tools for installation, while others offer tool-free designs, which can save time and reduce labor costs. Understanding the assembly process and ease of access to the fittings can influence the choice of fitting for a given application. Furthermore, system pressure and temperature ratings must be adhered to prevent failures and ensure optimal performance. Each fitting should be evaluated for its ratings against the specific demands of the system in which it will be used.

| Type | Description | Applications |

|---|---|---|

| Push-to-Connect | Quick and tool-affordable connections | General industrial use, automation systems |

| Compression | Tight seal for high-pressure systems | Heavy machinery, high-pressure applications, hydraulic systems |

| Barbed | Reliable connection for flexible hoses | Automotive, healthcare devices, fluid transfer applications |

| Threaded | Secure connections with male and female threads | General industrial use, high-pressure systems |

| Quick Disconnect | Fast attachment and detachment of components | Applications requiring frequent component changes |

Regular maintenance of pneumatic fittings is essential to ensure longevity and safety. This includes inspecting fittings for signs of wear, corrosion, or damage and replacing them as necessary. Proper installation and adherence to manufacturer guidelines are also critical to prevent leaks and potential system failures. Leaks in a pneumatic system can lead to inefficiencies, increased energy consumption, and can compromise the safety of equipment and personnel.

Additionally, understanding the environmental conditions, such as exposure to chemicals or extreme temperatures, can help in selecting the appropriate fittings to prevent premature degradation. For instance, fittings used in corrosive environments should be made from materials that resist chemical reactions, while those in high-temperature applications should be rated accordingly. Regular inspections should also include checking for signs of fatigue or stress, especially in systems that experience frequent vibrations or thermal cycling.

Another vital aspect of maintenance is ensuring that all fittings are adequately tightened and secured. Loose fittings can lead to air loss, which can adversely affect the performance of the entire system. It is important to follow torque specifications provided by manufacturers and to use proper tools to achieve the correct tightness. Furthermore, labeling fittings can help in tracking their condition and schedule for inspection or replacement.

Training personnel on the proper handling and installation of pneumatic fittings is also essential. Workers should be educated on the importance of selecting the right fittings for their application and the implications of using incorrect fittings, which can lead to system failures. By fostering a culture of safety and awareness, organizations can minimize risks associated with pneumatic systems.

The pneumatic fittings industry is evolving with advancements in technology and materials. Innovations such as smart fittings, which can monitor system performance and detect leaks, are becoming increasingly popular. These smart fittings utilize sensors and connectivity features to provide real-time data on system conditions, enabling predictive maintenance and reducing downtime. By proactively identifying issues before they lead to failures, organizations can save costs and improve operational efficiency.

Additionally, the development of eco-friendly materials and coatings is gaining traction, driven by the growing emphasis on sustainability in industrial practices. Manufacturers are exploring biodegradable plastics and more sustainable materials that reduce environmental impact without compromising performance. As industries continue to prioritize sustainability, the demand for environmentally friendly pneumatic fittings is expected to rise.

Furthermore, the integration of pneumatic systems with other technologies, such as IoT (Internet of Things) and automation, is transforming how pneumatic fittings are designed and utilized. The ability to communicate and share data across systems allows for enhanced control and optimization of pneumatic operations. For instance, pneumatic systems integrated with IoT can automatically adjust pressure levels based on real-time data, improving efficiency and reducing energy consumption.

As the industry progresses, the focus on modularity and versatility in fitting designs is also expected to increase. Modular fittings allow for easier customization and adaptation to specific applications, enabling manufacturers to create solutions that meet diverse customer needs. This flexibility can lead to more efficient systems that are better equipped to handle varying operational requirements.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!