The T600 5a is a cutting-edge technological innovation poised to revolutionize its area of application by offering improved efficiency and performance. Known for its advanced features, the T600 5a stands out in the competitive landscape, promising enhancements that appeal to developers and users alike. This exploration delves into the intricate workings, advantages, and industry implications of adopting the T600 5a.

The T600 5a is rapidly becoming a pivotal tool within its domain, capturing interest from industry leaders and engineers worldwide. As a state-of-the-art piece of technology, it promises to unlock new levels of operational efficiency and capability. With its advanced engineering design, the T600 5a not only enhances performance but also ensures sustainability and ease of use. Emphasizing innovation, it integrates cutting-edge features that meet the diverse needs of modern industries, thus orbiting around the principal goal of productive advancement.

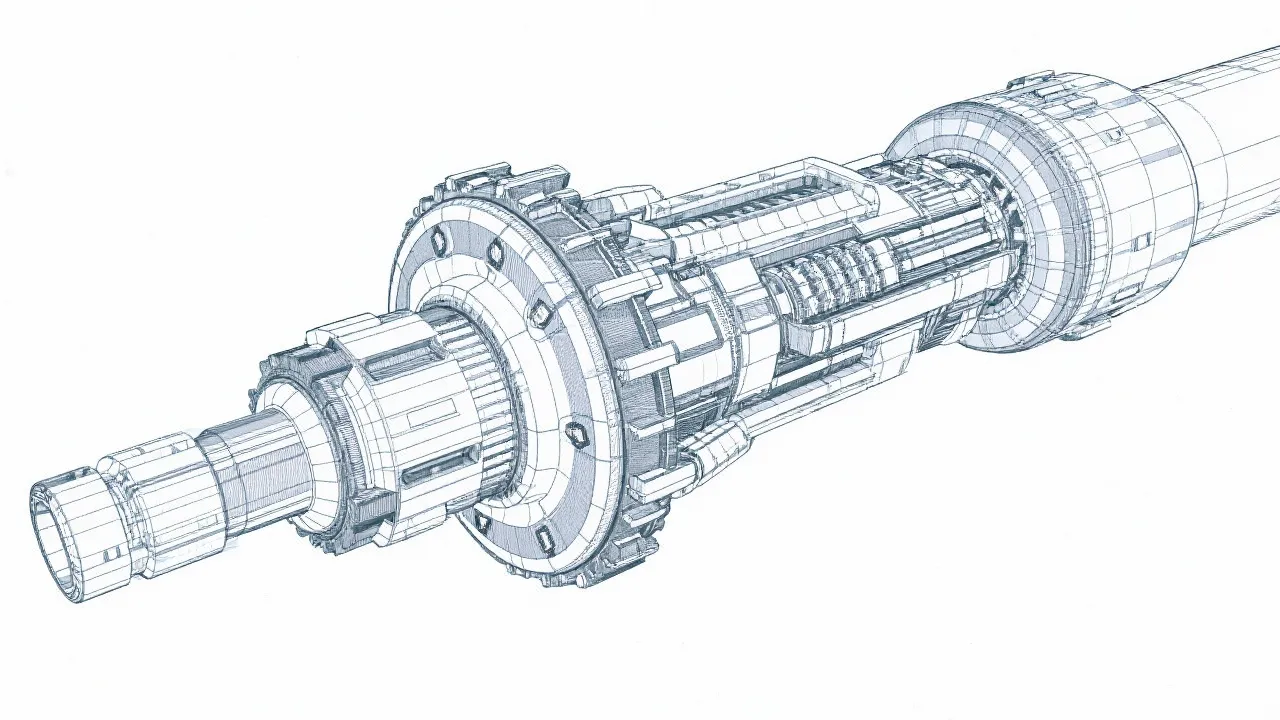

What sets the T600 5a apart from its counterparts is its array of sophisticated features. This equipment integrates seamless functionality with a sturdy build, reflecting a harmonious blend of innovation and reliability. Among its standout components are the intelligent control systems, precision engineering, and enhanced power efficiency. Each feature has been meticulously designed to meet the evolving demands of its users, ensuring adaptability and longevity.

One such notable feature of the T600 5a is its intelligent control system, which employs advanced algorithms to optimize operations dynamically. This system learns from usage patterns, adapting settings to enhance productivity while minimizing energy use. For example, during periods of high demand, the system automatically ramps up performance without compromising efficiency. Another significant specification is its modular design, which enables easy customization and scalability according to specific industry requirements. This allows businesses to tailor the T600 5a to fulfill unique tasks, ranging from routine operations to highly specialized projects.

Furthermore, the T600 5a incorporates a user-friendly interface that simplifies operation and reduces training time for personnel. This interface includes interactive touchscreens and real-time data analytics that provide operators with immediate feedback and insights into performance metrics. Such a design not only enhances user experience but also facilitates quick decision-making, which is essential in fast-paced industrial environments. The combination of these features signifies a comprehensive technological advancement that redefines productivity benchmarks across various sectors.

The T600 5a finds applications in various sectors ranging from industrial manufacturing to high-tech research facilities. Its versatility enables it to handle complex tasks with exceptional precision, making it a preferred choice for numerous projects. for instance, in the aerospace industry, the T600 5a is used in the production of lightweight composite materials, which are integral for modern aircraft. The precision engineering capabilities deliver components that meet stringent safety and performance standards, which are essential for flight safety.

Additionally, the T600 5a is making waves in the automotive sector, where its ability to manage high-speed assembly lines is revolutionizing production methodologies. Factories equipped with the T600 5a report unprecedented improvements in throughput and quality control. The equipment enhances component tracking through RFID technologies, ensuring that parts are assembled accurately and efficiently. Moreover, its role in high-tech research and development facilities cannot be underestimated. Researchers are utilizing the T600 5a to prototype advanced materials, thereby accelerating the path from concept to reality. The machine's adaptability allows for experimentation with innovative designs and structures that push the boundaries of traditional manufacturing.

In the pharmaceutical industry, the T600 5a has been deployed to improve the consistency and accuracy of drug production. Automated processes minimize human error in the critical phases of manufacturing and packaging medications, which directly impacts patient safety and efficacy. The integration of the T600 5a into such diverse fields paints a clear picture of its importance and the growing adoption rate across industries.

In comparison to previous models, the T600 5a offers up to a 20% increase in energy efficiency, backed by a comprehensive industry report from Tech Research Corp. This advance translates into reduced operational costs and a lower environmental footprint. These improvements underscore the commitment to fostering sustainable practices across industrial applications. The increase in energy efficiency is due to several factors, including improved motor technology and energy recovery systems that reuse power generated during operation.

Moreover, the T600 5a boasts an enhanced lifecycle management feature, which allows users to monitor the health status of components in real time. This capability significantly reduces maintenance costs and downtime, as businesses can proactively address potential failures before they become critical. By transitioning to predictive maintenance schedules instead of reactive ones, companies not only save on repair costs but also extend the overall lifespan of the machinery.

The T600 5a is also equipped with advanced safety mechanisms that surpass those of its predecessors. These systems include automatic shut-off features in the event of mechanical failure or unsafe operating conditions, protecting both personnel and machinery. As companies continue to prioritize employee safety alongside productivity, the T600 5a’s safety features become a crucial selling point.

Recently, a renowned automotive manufacturer adopted the T600 5a in their production line. The transition led to substantial improvements in assembly speed and accuracy, reducing overall downtime by 30%. This case study exemplifies the significant impacts the T600 5a can have when deployed strategically in dynamic settings. The manufacturer faced several challenges, including inefficient workflows and outdated machinery that could not keep pace with modern demands. Upon implementing the T600 5a, they noted an immediate transformation.

Within the first quarter of operation, production rates skyrocketed, leading to an increase of approximately 25% in output without additional overtime costs. The operator interface allowed employees to quickly learn how to manage the machinery, drastically reducing training time and facilitating smoother transitions. Furthermore, quality control metrics improved, with defects dropping by 15% due to precise calibration and real-time monitoring capabilities. Employee satisfaction also saw a marked increase, as workers felt empowered by the new technology, contributing to higher morale and productivity.

This case study clearly illustrates how the T600 5a not only optimizes production processes but also creates a more engaging and efficient workplace. As companies look to modernize their operations, the success story of this automotive manufacturer serves as a powerful testament to the potential of the T600 5a.

Q: What maintenance is required for the T600 5a?

A: Regular maintenance includes software updates, component checks, and cleaning procedures to ensure optimal performance. Users should also engage in periodic training for staff to remain updated on maintenance techniques and safety protocols.

Q: How does the T600 5a contribute to sustainability?

A: By optimizing energy usage and incorporating recyclable materials, the T600 5a contributes to reducing its environmental impact. Included in its design is a circular economy approach that encourages the use of sustainable resources, furthering a commitment to ecological responsibility.

Q: Are there warranties available when purchasing the T600 5a?

A: Yes, the T600 5a comes with an extensive warranty, ensuring support and coverage for repairs during the initial years of operation. Additional extended service plans are also available to enhance user confidence and protect investments.

Q: Can the T600 5a be integrated with existing systems?

A: The T600 5a is designed with compatibility in mind, allowing for smooth integration with legacy systems. Many facilities have successfully connected the T600 5a with previous models and software platforms, facilitating a seamless upgrade path.

Q: What industries are most likely to benefit from the T600 5a?

A: While the T600 5a is versatile, industries such as automotive, aerospace, pharmaceuticals, and electronics manufacturing stand to gain significantly from its features. Each sector’s unique requirements are met through customizable solutions enabled by the T600 5a's design.

The T600 5a represents a significant leap in technological capability and environmental responsibility. Its introduction into various sectors promises to redefine standards, paving the way for future innovations. As industries seek tools that combine efficiency with precision, the T600 5a stands out as a commendable choice. Its advancements serve as a catalyst for broader transformations in manufacturing, fostering not only improved productivity but also an enduring commitment to sustainability and workforce empowerment.

| Term | Definition |

|---|---|

| Energy Efficiency | The ability to use less energy to perform the same task, thereby reducing overall energy consumption. |

| Precision Engineering | An approach that emphasizes precise measurements and controls in manufacturing and processing. |

| Predictive Maintenance | A proactive maintenance strategy designed to predict when equipment is likely to fail so that maintenance can be performed just in time, minimizing downtime and costs. |

| Modular Design | A design principle that breaks a system into smaller parts (modules) that can be independently created, modified, and replaced. |

| Circular Economy | An economic system aimed at eliminating waste and the continual use of resources through reuse, repair, refurbish, and recycling. |

| RFID Technology | A wireless technology that uses electromagnetic fields to automatically identify and track tags attached to objects. |

As industries evolve, so too will the capabilities and applications of the T600 5a. Research and development teams are actively working on enhancing the machine’s features further. Prospective upgrades may include artificial intelligence (AI) integration for even smarter operations, advanced data analytics for predictive modeling, and enhanced connectivity features to support the Internet of Things (IoT).

AI can enable the T600 5a to not only perform its tasks but also intelligently adjust its operations based on real-time data analysis, optimizing performance continuously. Furthermore, with the increasing importance of data in decision-making, the ability to analyze large volumes of operational data could provide deeper insights into efficiency and productivity trends. This will foster not only operational innovation but also strategic decision-making rooted in concrete data analytics.

Moreover, as sustainability continues to be a primary focus for industries worldwide, future iterations of the T600 5a may incorporate new materials and processes designed specifically with environmental stewardship in mind. Ideas surrounding carbon-neutral production techniques and the use of biodegradable components may redefine manufacturing norms and set new industry benchmarks.

As we look toward the future, the T600 5a stands poised to lead the way in manufacturing technology, embracing trends that prioritize efficiency, innovation, and an ethical approach to production. The commitment to driving forward this trajectory will not only enhance operational success but will also bolster the reputation of users as leaders in responsible and productive manufacturing.

Successfully integrating the T600 5a into existing operations involves thoughtful planning and strategic execution. Companies considering the T600 5a should approach its adoption in phases, beginning with a thorough assessment of current processes. Understanding strengths, weaknesses, and potential areas for improvement can guide stakeholders in leveraging the full potential of the T600 5a.

Next, stakeholders should engage in comprehensive training programs for employees. An informed workforce is key to realizing the machine's benefits, so investing in ongoing education ensures all personnel, from operators to management, are equipped to maximize the technology’s capabilities. Training should encompass not only the technical aspects of the T600 5a but also how to interpret data and analytics generated during its operation, fostering a culture of informed decision-making.

Furthermore, involving cross-functional teams in the planning and implementation process can contribute to a smoother transition. Such collaboration ensures that insights from various departments are integrated, addressing potential concerns across operation lines and aligning the new system with overarching business objectives. Continuous feedback loops during the initial implementation phase should be encouraged, allowing for quick adjustments and optimizations as users become acquainted with the technology.

Lastly, companies should regularly review their return on investment (ROI) associated with the T600 5a. By analyzing performance data and operational metrics, organizations can ensure that they are reaping the intended benefits of this advanced machinery. Performance reviews can also uncover new opportunities for further improvement, and adaptation based on experiences can facilitate ongoing advancements in operational efficiency and effectiveness.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!