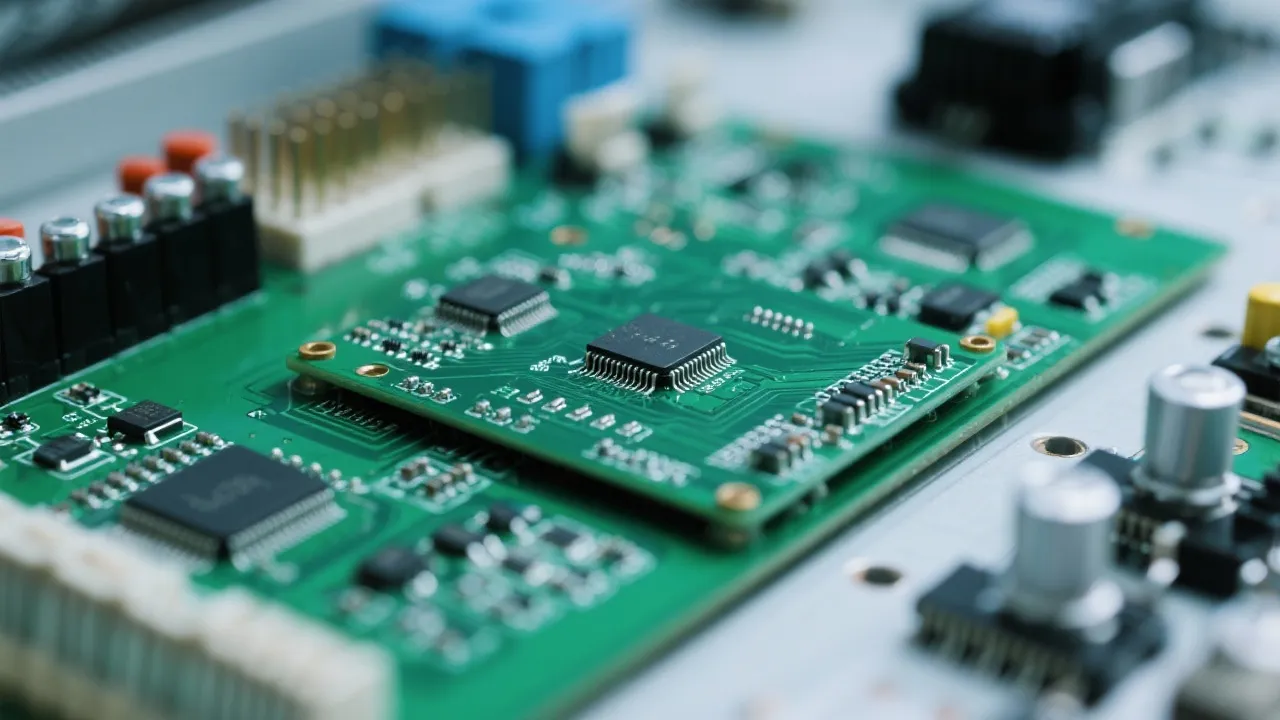

Dive into the world of Jac Pcd, a pivotal component in the microelectronics industry. This article explores its importance, application, and impact on the development and enhancement of electronic devices. Jac Pcd technology is vital for manufacturing precision components, enabling advancements in electronic products from consumer gadgets to industrial machinery.

In the fast-paced world of microelectronics, precision, durability, and efficiency are paramount. Among the key players driving innovation in this industry is Jac Pcd—a cutting-edge technology instrumental in the creation of complex electronic components. This article endeavors to provide a comprehensive understanding of Jac Pcd, exploring its role, benefits, and applications in the ever-evolving realm of microelectronics. As microelectronics continues to grow at an unprecedented rate, the necessity for advanced manufacturing solutions has never been more evident. Jac Pcd stands at the forefront of this evolution, enabling manufacturers to produce highly sophisticated devices while maintaining rigorous quality standards.

Jac Pcd, or Polycrystalline Diamond (PCD) tools, are made from synthetic diamond particles bonded on a material base, commonly used in cutting and machining applications. Known for their extraordinary hardness and wear resistance, these tools are integral to the microelectronics industry, where precision is non-negotiable. Within the structure of Jac Pcd, millions of diamond crystals interlock to form a dense, robust material capable of withstanding extreme conditions. This configuration not only provides exceptional hardness but also equips Jac Pcd tools with the ability to maintain their sharpness for longer durations compared to traditional materials, making them a game-changer in precision engineering. The use of PCD extends beyond mere manufacturing, influencing the overall efficiency and lifespan of the components they create.

Jac Pcd technology stands out for its unparalleled ability to manage heat and sustain sharpness over prolonged periods. This makes it an ideal choice for the intricate demands of microelectronic fabrication, where even the tiniest error can lead to significant functionality issues. In high-precision environments such as semiconductor wafer production, the ability to create flawless cuts reduces wastage and enhances yield. The durability of PCD ensures extended lifecycles of tools, minimizing downtime and boosting productivity in microelectronic manufacturing processes. Furthermore, the adoption of Jac Pcd is not limited to cutting; it also extends to grinding, drilling, and various other machining operations that require exacting tolerances and surface finishes. This versatility solidifies its position as an indispensable asset in modern manufacturing landscapes.

Jac Pcd is extensively used in the manufacture of various electronic components including semiconductors, integrated circuits, and other critical hardware involved in consumer electronics and industrial machinery. Its unique properties allow for intricate designs and tolerances to be achieved, paving the way for the creation of next-generation electronics with improved performance and efficiency. The application of Jac Pcd tools is not limited to just contemporary techniques; they are also integral in advanced technologies like 3D printing and micro-electromechanical systems (MEMS). These developments significantly influence the miniaturization of components, greatly impacting sectors such as telecommunications, computing, and even aerospace.

| Application | Benefit |

|---|---|

| Semiconductor Fabrication | Enables precision cutting and shaping of semiconductor wafers, resulting in higher yield and lower waste. |

| Integrated Circuits | Facilitates the creation of complex circuit designs with high accuracy, improving overall performance and reliability. |

| Consumer Electronics | Enhances durability and performance of electronic components, catering to the demand for more robust devices. |

| Industrial Machinery | Improves efficiency and lowers replacement frequency of machine parts, saving costs on maintenance and downtime. |

| Telecommunications Equipment | Supports the production of high-frequency devices that require precise characteristics to function optimally. |

| Medical Devices | Ensures high-quality manufacturing of critical components, improving the safety and effectiveness of medical equipment. |

| Aerospace Components | Enables the production of lightweight, durable parts essential for aircraft efficiency and safety. |

Despite its valuable contributions, the integration of Jac Pcd in manufacturing comes with challenges. The high initial cost of PCD tools can be a barrier to entry for smaller firms, which may not have the budget to invest in such advanced equipment. In many cases, the return on investment is realized only over time, necessitating a careful financial analysis before adoption. Additionally, the specialized nature of these tools requires skilled personnel for optimal utilization and maintenance. This can lead to additional training costs and operational adjustments within the workforce. Nevertheless, the good benefits often outweigh these initial hurdles, especially for firms aiming to produce high-quality microelectronic components capable of competing in a rapidly evolving market. Furthermore, as the technology matures and becomes more widespread, prices are expected to decrease, enabling broader access to Jac Pcd's capabilities for a wider range of manufacturers.

The potential of Jac Pcd continues to grow as technological advancements are made in synthetic diamond production and processing techniques. Innovations targeting the reduction of costs and enhancement of performance metrics are underway, potentially expanding the adoption of these tools in the microelectronic industry and beyond. Emerging methodologies in chemical vapor deposition (CVD) techniques have made the synthetic diamond manufacturing process more efficient and affordable. This continuous evolution of PCD technology promises further miniaturization and enhancement of electronic devices, making it possible for manufacturers to produce safer, faster, and more efficient devices. Look for ongoing research into diamond electronics, which promises to unlock new possibilities in high-power, high-frequency applications. The integration of Jac Pcd with artificial intelligence (AI) and machine learning technologies also signals a leap forward, as these tools can be combined to optimize processes and predict maintenance needs before tool failure occurs.

A: Its exceptional hardness, sharpness longevity, and ability to manage thermal challenges make it essential for precision manufacturing in various microelectronic applications.

A: Yes, while initial costs are high, the extended durability, reduced maintenance requirements, and enhanced productivity contribute to significant long-term savings.

A: The microelectronics, automotive, aerospace, telecommunications, and medical device industries significantly benefit from Jac Pcd applications, leveraging its unique properties for enhanced product performance.

In conclusion, Jac Pcd represents a vital technological advancement in the microelectronics industry. As the demand for more sophisticated and efficient electronic devices continues to rise, the integration of PCD technology will likely play a critical role in meeting these demands, ensuring that industry standards and consumer expectations are not only met but exceeded. It's essential for manufacturers to stay ahead of this technological curve, adopting innovations that enable them to enhance their production capabilities. The strategic investment in Jac Pcd will not only improve their competitive edge but also contribute to a more sustainable technological future.

While Jac Pcd plays a crucial role in the microelectronics landscape, it is equally important to explore the broader context of advanced manufacturing practices that help to propel the industry forward. This includes topics such as automation, Industry 4.0, and sustainable practices which are increasingly relevant in today's environmentally-conscious market. Automated systems have revolutionized manufacturing by integrating robotics and intelligent systems to enhance production efficiency and scalability.

Furthermore, the advent of Industry 4.0 has significantly transformed traditional manufacturing paradigms through the incorporation of the Internet of Things (IoT), big data, and cloud computing. This interconnected framework facilitates real-time data analytics, predictive maintenance, and supply chain optimization, which directly complement the precision achieved with Jac Pcd tools. By analyzing data derived from production processes, manufacturers can make informed decisions leading to improved quality control and waste reduction.

On the sustainability front, the microelectronics industry faces mounting pressure to minimize its environmental footprint and adopt cleaner production methods. Jac Pcd’s durability translates to less frequent tool replacements, resulting in lower material waste and resource usage. Furthermore, manufacturers are now exploring more sustainable approaches in the sourcing of materials used for microelectronics, including ethically produced components that align with the values and expectations of modern consumers. In striving for a balance between advanced technology and sustainability, the industry is not only improving its practices but also enhancing its public image and brand trust.

As technological advancements continue to emerge, the interdisciplinary approach encompassing Jac Pcd and broader manufacturing contexts will be vital in fostering a proactive and innovative microelectronics industry poised for future challenges. Manufacturers are encouraged to not only invest in state-of-the-art tools and technologies but also in their workforce—the true heart of any company—ensuring they are equipped with the skills required to thrive in a constantly evolving landscape.

In summation, the journey of microelectronics is one marked by rapid advancement and an ever-increasing demand for precision, efficiency, and sustainability. Jac Pcd stands at the apex of this evolution, offering unique advantages that cater to a diverse range of applications across various industries. By embracing the benefits of Jac Pcd, manufacturers can not only elevate their production capabilities but also contribute to the larger narrative of technological innovation and sustainability in the world of microelectronics. It is indeed a critical moment for the industry; one that calls for collaboration, knowledge sharing, and a shared vision for the future. Moving forward, staying abreast of technological trends and innovations, like those offered by Jac Pcd, will be essential in redefining the possibilities within microelectronics, ensuring continued growth and success in a competitive landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!