Polysulfide adhesives are versatile compounds used for their excellent sealing and adhesive properties. Originating in the mid-20th century, they are known for their resistance to chemicals, weathering, and flexibility. This article delves into their applications, benefits, and considerations for use, providing a comprehensive overview for industries relying on robust adhesive solutions.

Polysulfide adhesives stand out in the adhesive industry due to their unique properties. Known for their resilience and adaptability, these adhesives are widely used in sectors requiring strong, durable bonds. Their ability to withstand harsh environmental conditions makes them indispensable in industries such as construction, automotive, and aerospace. Unlike many other adhesive types, polysulfide adhesives can maintain their performance over time, even when subjected to extreme conditions. This quality is what sets them apart and makes them a preferred choice for many critical applications.

The intrinsic properties of polysulfide adhesives include chemical resistance, flexibility, and weatherproofing. These characteristics ensure they maintain their bond strength even when exposed to aggressive chemicals, temperature fluctuations, or moisture. Consequently, they are often the adhesive of choice for applications that demand longevity and reliability. Furthermore, polysulfide adhesives exhibit excellent adhesion to a wide variety of substrates, including metals, glass, and plastics, enhancing their versatility across different applications.

One of the most significant benefits of polysulfide adhesives is their flexibility. This flexibility allows them to absorb shock and vibration, making them suitable for applications in dynamic environments. Additionally, their low shrinkage rate during curing means that the adhesive does not pull away from the bonded surfaces, maintaining a strong bond over time. The curing process itself can take place at room temperature, although the use of heat can accelerate it, providing manufacturers with options depending on their production schedules.

Moreover, polysulfide adhesives are also resistant to various environmental factors such as ozone, saltwater, and extreme temperatures, making them ideal for marine applications as well. Their ability to perform in challenging conditions means they are often used in infrastructure projects, including bridges and tunnels, where longevity and durability are critical. The ease of application and the availability of various formulations further add to their appeal, allowing for tailored solutions based on specific project requirements.

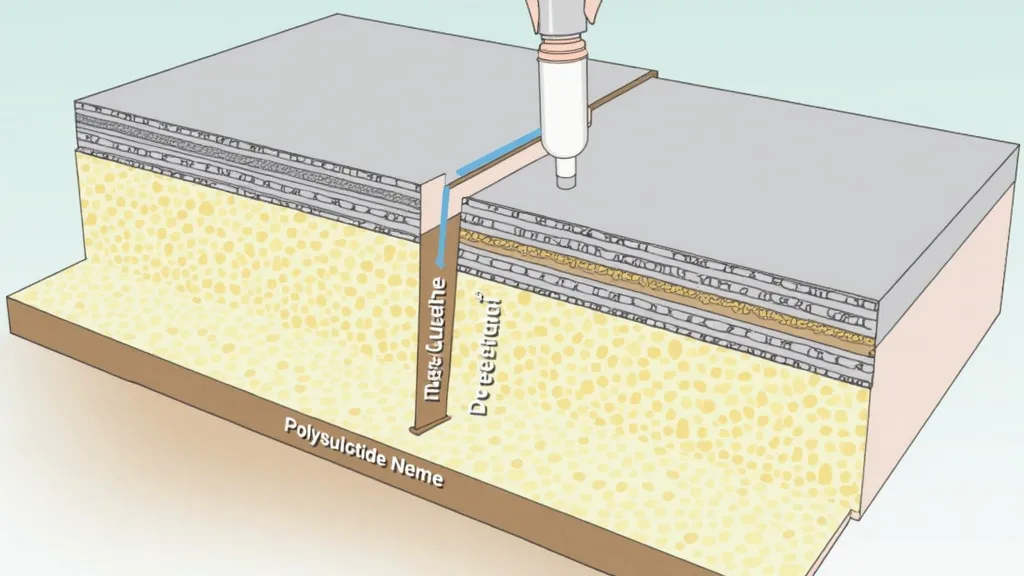

In the construction industry, polysulfide adhesives are primarily used for sealing joints and insulating glass units. Their ability to form a flexible seal that can accommodate movement makes them ideal for applications in building facades and window glazing. This flexibility is crucial in preventing water ingress and ensuring energy efficiency in buildings, which is a growing concern in modern architecture. Additionally, polysulfide adhesives are often used in the installation of curtain walls, skylights, and other architectural features that require a reliable, weather-resistant seal.

In the automotive sector, these adhesives are used for sealing fuel tanks and other components exposed to fuels and oils. The automotive market also utilizes polysulfide adhesives for bonding windshields and other glass parts, where a durable, flexible bond is necessary to withstand the stresses of driving. Their resistance to harsh automotive chemicals, including gasoline and oils, ensures that the bond remains intact over the vehicle's lifespan, contributing to vehicle safety and structural integrity.

The aerospace industry also benefits from polysulfide adhesives due to their resistance to fuel and hydraulic fluids. They are used in the sealing of aircraft fuel tanks and in other areas where exposure to such substances is a concern. The lightweight nature of polysulfide adhesives is an additional advantage in aerospace applications, where weight reduction is critical for improving fuel efficiency. Furthermore, the ability to bond dissimilar materials like metals and composites is vital in aerospace, making polysulfide adhesives an integral part of modern aircraft design.

Beyond these primary industries, polysulfide adhesives find applications in the manufacturing of electrical and electronic devices, where their insulating properties can protect sensitive components from moisture and environmental damage. They are utilized in potting applications, where electronic components are encased in a protective resin to prevent failure due to exposure to water or contaminants. This versatility extends to the medical field, where polysulfide adhesives can be found in certain medical devices and equipment, given their biocompatibility and ability to bond various materials.

| Adhesive Type | Key Properties | Typical Uses |

|---|---|---|

| Polysulfide | Flexible, chemical resistant, weatherproof | Construction, automotive, aerospace |

| Epoxy | High strength, rigid, heat resistant | Structural bonding, electronics |

| Polyurethane | Elastic, moisture resistant, versatile | Flooring, automotive, footwear |

| Cyanocrylate | Fast curing, strong adhesion, brittle | Quick repairs, light-duty applications |

| Silicone | High elasticity, temperature resistant, waterproof | Sealing, gaskets, plumbing applications |

This comparative analysis highlights the unique advantages of polysulfide adhesives, particularly in environments where flexibility and chemical resistance are critical. While epoxy adhesives provide high strength and rigidity suitable for structural applications, they may not offer the same level of flexibility as polysulfide adhesives. Polyurethane adhesives are versatile and moisture resistant, making them suitable for a variety of applications; however, they can sometimes lack the chemical resistance offered by polysulfides. Understanding the properties of different adhesives is essential for selecting the right material for a specific application.

Selecting the appropriate adhesive requires an understanding of the specific demands of the application, including environmental exposure, mechanical stress, and material compatibility. Polysulfide adhesives are particularly suitable for scenarios where flexibility and chemical resistance are paramount. For instance, in construction projects that involve exposure to severe weather conditions, polysulfide adhesives can provide the necessary durability and long-term performance.

When choosing an adhesive, it is also essential to consider the curing time and conditions. Polysulfide adhesives typically cure at room temperature, but the speed of curing can be affected by humidity and temperature. In situations where a faster cure time is required, selecting a formulation with accelerated curing properties may be beneficial. Additionally, it is important to assess the bonding surfaces; polysulfide adhesives bond well to porous and non-porous materials alike, but surface preparation can enhance adhesion. Cleaning surfaces to remove dust, grease, and contaminants is crucial for achieving optimal bond strength.

The application method is another critical consideration. Polysulfide adhesives are often dispensed using caulking guns, allowing for easy application in various configurations. For larger surfaces, bulk application methods may be employed, enabling efficient coverage. Tooling the adhesive after application can help achieve a smooth finish and ensure complete contact with the surfaces being bonded. Depending on the application, it may also be beneficial to conduct tests or trials to evaluate the adhesive's performance under expected conditions.

Their resistance to UV light and weathering ensures that polysulfide adhesives maintain their integrity when exposed to outdoor elements. This quality is particularly important in construction and automotive applications, where long-term exposure to sunlight and rain can degrade other adhesive types. The flexibility of polysulfide also helps it to accommodate thermal expansion and contraction, reducing the risk of bond failure over time.

While they can endure a range of temperatures, for extremely high-temperature applications, other adhesives like epoxies might be more suitable. Polysulfide adhesives typically perform well in moderate temperature ranges, but their performance can diminish at temperatures exceeding their specified limits. It's crucial to consult technical data sheets for specific formulations to ensure they meet the temperature requirements of the intended application.

Application typically involves the use of a caulking gun for even distribution, followed by tooling to ensure a smooth, consistent seal. Depending on the specific formulation, some polysulfide adhesives may be applied using spray equipment for larger projects. It is essential to follow the manufacturer's instructions regarding curing times, application temperatures, and surface preparation to achieve optimal performance.

Polysulfide adhesives are known for their superior chemical resistance and flexibility compared to many other types of sealants. For instance, while silicone sealants offer excellent flexibility and weather resistance, they may not provide the same level of chemical resistance needed in certain applications such as automotive or industrial environments. Conversely, polyurethane sealants can be more elastic than polysulfides but may not withstand harsh chemicals as effectively. Therefore, the choice between these materials depends on the specific needs of the project.

Yes, while polysulfide adhesives are durable and effective, they can contain solvents and other chemicals that may have environmental impacts. It is advisable to check for low-VOC (volatile organic compounds) formulations or eco-friendly alternatives if environmental considerations are a priority. Moreover, proper disposal methods should be followed to minimize environmental harm once the adhesive has reached the end of its lifecycle.

The future of polysulfide adhesives looks promising, with ongoing research aimed at enhancing their properties and broadening their applications. Innovations in formulations may lead to improved curing times, better adhesion to a wider range of substrates, and enhanced environmental resistance. Additionally, as industries seek more sustainable solutions, the development of bio-based polysulfide adhesives could become a significant trend, reducing reliance on petroleum-based chemicals.

Another area of advancement may focus on the integration of polysulfide adhesives with smart technologies. For example, adhesives that can change properties based on environmental stimuli (like temperature or humidity) could open up new possibilities in various industries, including construction and electronics. These smart adhesives could potentially provide real-time feedback on adhesive integrity and environmental conditions, further enhancing safety and performance in critical applications.

Furthermore, the growing emphasis on energy efficiency and sustainability in construction and manufacturing is likely to drive demand for high-performance adhesives like polysulfides. As buildings and vehicles become more complex, the need for reliable bonding solutions that can withstand diverse environmental challenges will continue to rise. This trend underscores the importance of ongoing research and development in the field of polysulfide adhesives, ensuring that they remain at the forefront of adhesive technology.

In conclusion, polysulfide adhesives offer a robust solution for industries that demand durable, flexible bonding agents. Their adaptability to various conditions and compatibility with different substrates underscore their value in modern industrial applications. Whether it's in the construction of energy-efficient buildings, the manufacturing of high-performance vehicles, or the advancement of aerospace technology, polysulfide adhesives play a critical role in ensuring the reliability and longevity of bonded structures and components.

As technology continues to advance, the role of polysulfide adhesives will likely expand, paving the way for innovative applications and enhanced performance in a variety of fields. Industry professionals must remain informed about the latest developments and best practices in adhesive selection and application to fully leverage the benefits that polysulfide adhesives have to offer.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!