This article delves into the versatile applications and benefits of polysulfide adhesive, a robust sealing solution used widely across industries. Known for its excellent resistance to chemicals and weathering, polysulfide adhesive is a preferred choice in aerospace, automotive, and construction sectors, offering durability and flexibility in various conditions.

Polysulfide adhesive is a synthetic polymer known for its exceptional sealing properties and flexibility. It is frequently used in industries where durability and resistance to environmental factors are paramount. With its unique chemical composition, polysulfide adhesive remains a staple in sectors such as aerospace, automotive, and construction. Understanding its formulation and the science behind its properties is crucial for professionals who rely on these adhesives in their projects.

The chemistry of polysulfide adhesives involves long chains of sulfur atoms, which contribute to their unique characteristics. These chains create a flexible network that allows for movement while retaining strength. This property is particularly beneficial in applications where materials may expand, contract, or otherwise change shape due to thermal or mechanical stress. In addition to its flexibility, polysulfide adhesive exhibits excellent adhesion to a variety of substrates, including metals, plastics, and glass, making it a versatile choice for many applications.

Polysulfide adhesive stands out due to its resistance to fuels, chemicals, and weathering. This makes it particularly useful in applications that demand longevity and reliability under harsh conditions. Its elasticity allows it to accommodate movement, making it ideal for sealing joints and surfaces that may undergo expansion or contraction. Moreover, polysulfide adhesive retains its performance over time, which is crucial for long-term projects.

Another significant benefit of polysulfide adhesives is their ability to seal effectively against moisture and air infiltration. This characteristic is critical in applications such as window sealing, where preventing water ingress can protect structural integrity and improve energy efficiency. Additionally, polysulfide adhesives are often resistant to UV light, further extending their lifespan in outdoor applications.

Polysulfide adhesives typically have a longer curing time than some other adhesive types, which can be an advantage in certain contexts. The extended working time allows for adjustments during application, ensuring that the adhesive can be positioned correctly before it begins to set. This feature is especially beneficial in complex assemblies where precise alignment is crucial.

The versatility of polysulfide adhesive allows it to be implemented across various industries. In aerospace, it is used to seal fuel tanks and aircraft windows due to its resistance to aviation fuels. The aerospace sector demands materials that can withstand extreme conditions, including high altitudes and significant temperature variations, making polysulfide an ideal choice.

In the automotive industry, it provides a reliable seal for windshields and body panels. The flexibility and durability of polysulfide adhesives help ensure that these seals maintain their integrity over time, even when exposed to harsh weather conditions and road vibrations. Additionally, polysulfide adhesives are used in bonding various automotive components, contributing to overall vehicle safety and performance.

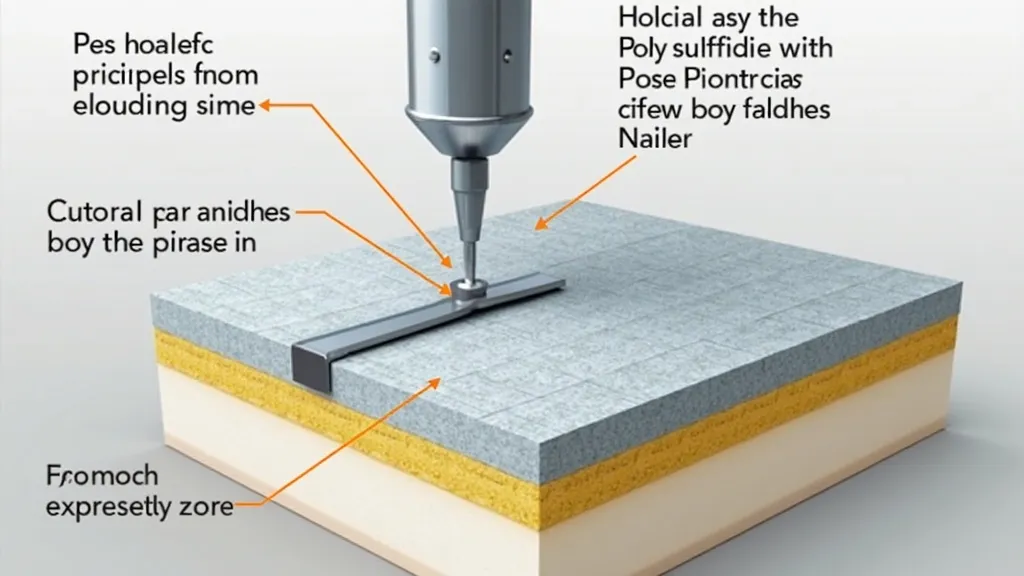

The construction sector utilizes polysulfide adhesives for sealing expansion joints and curtain wall systems, ensuring longevity and structural integrity. These adhesives are particularly beneficial in high-rise buildings where movements due to wind and thermal expansion can be significant. By accommodating these movements, polysulfide adhesives help prevent cracking and other forms of damage to both the facade and the structural elements of the building.

Furthermore, polysulfide adhesives are also employed in the manufacturing of electronic devices, where sealing components against moisture is crucial. In these applications, the adhesive’s electrical insulation properties are essential, as they help protect sensitive electronic parts from corrosion and damage.

| Property | Polysulfide Adhesive | Silicone Sealant | Polyurethane Sealant |

|---|---|---|---|

| Elasticity | High | Moderate | Moderate |

| Chemical Resistance | Excellent | Good | Good |

| Weather Resistance | Excellent | Excellent | Good |

| Durability | High | Moderate | High |

| Cost | Moderate | Low | Moderate |

When comparing polysulfide adhesive to silicone and polyurethane sealants, it is essential to consider the specific requirements of the application. While silicone sealants are often favored for their ease of use and lower cost, they may not provide the same level of chemical resistance as polysulfide adhesives. Silicone is also less effective in applications where high movement accommodation is necessary.

Polyurethane sealants, on the other hand, offer strong adhesion and excellent durability, but they can be more sensitive to moisture during the curing process. This is where polysulfide adhesives provide a unique advantage; they can cure effectively in moist environments, making them suitable for various applications where humidity is a concern.

Cost is another factor that influences the choice of adhesive. While polysulfide adhesives may be priced higher than silicone sealants, the long-term benefits and durability often justify the investment, especially in critical applications where failure is not an option.

Industry experts highlight the importance of choosing the right adhesive based on specific application needs. Polysulfide adhesive is recommended for projects that require strong chemical resistance and elasticity. However, it is crucial to consider factors such as curing time and compatibility with different materials. Experts advise conducting adhesion tests when applying polysulfide adhesive to new substrates to ensure optimal performance.

Additionally, it is essential to prepare surfaces properly before applying polysulfide adhesive. Cleaning and priming surfaces can significantly enhance adhesion and ensure that the adhesive performs as expected. Manufacturers often provide specific guidelines on surface preparation, which should be followed closely to avoid potential issues.

In applications where movement is anticipated, such as in expansion joints, polysulfide adhesives should be selected with the appropriate modulus to accommodate the expected deformation. A low modulus adhesive will provide greater flexibility, while a high modulus adhesive may offer more strength but less movement accommodation. Understanding the movement characteristics of the materials being bonded is critical for selecting the right polysulfide adhesive.

Polysulfide adhesive typically cures at room temperature, but the process can be accelerated with heat. It is important to follow the manufacturer's guidelines for optimal curing conditions. The curing time can vary significantly based on the thickness of the application and environmental conditions, such as humidity and temperature.

Yes, once fully cured, polysulfide adhesive can be painted over. It is advisable to use paint that is compatible with the adhesive to ensure adhesion and durability. Some paints may not adhere well to polysulfide surfaces, so conducting a test on a small area before applying paint to the entire surface is a wise decision.

While polysulfide adhesive offers excellent performance, it is essential to handle and dispose of it responsibly to minimize environmental impact. Many manufacturers are working towards more sustainable formulations, and some products are now available with reduced volatile organic compounds (VOCs). It is advisable to check for eco-friendly options if environmental considerations are a priority for your project.

Polysulfide adhesives are known for their stability and performance across a broad temperature range. They can typically withstand extreme temperatures from -60°F to 250°F (-51°C to 121°C) without losing their adhesive properties. This makes them suitable for applications in environments subject to fluctuating temperatures, such as outdoor settings and industrial environments.

Yes, when working with polysulfide adhesive, it is essential to follow safety precautions. This includes wearing protective gloves and eye protection to prevent skin and eye contact. Adequate ventilation is also crucial, especially in enclosed spaces, to avoid inhaling fumes. Always refer to the safety data sheet (SDS) provided by the manufacturer for specific handling and safety instructions.

Polysulfide adhesive remains a critical component in various industrial applications due to its outstanding properties. Whether it's in aerospace, automotive, or construction, its ability to withstand harsh environments and maintain flexibility makes it an invaluable tool for professionals seeking reliable sealing solutions. As industries continue to evolve and demand higher performance materials, polysulfide adhesives are likely to remain at the forefront, adapted for new applications and innovations.

In summary, the unique formulation of polysulfide adhesive provides advantages that are difficult to replicate with other adhesive types. Its superior chemical resistance, durability, and flexibility make it suitable for critical applications where reliability is non-negotiable. As advancements in adhesive technology continue, the role of polysulfide adhesives in various sectors will likely expand, offering even more innovative solutions to meet the challenges of modern engineering and construction.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!