Aerospace vibration isolators play a crucial role in maintaining the structural integrity and operational functionality of aerospace systems. These components are essential for minimizing unwanted vibrations that can affect both performance and safety. Engineered to endure extreme conditions, they are integral to the aerospace industry's continuous push for enhanced efficiency and reliability.

Aerospace vibration isolators are a vital component in the design and functionality of modern aircraft. They are engineered to mitigate vibrations and shocks that may arise during flight, ensuring that sensitive components and passengers remain unaffected by these disruptive forces. Vibration isolators help maintain the integrity and longevity of aerospace systems, which face unique challenges due to the broad range of frequencies and intensities experienced in flight conditions.

The role of aerospace vibration isolators is primarily to protect delicate avionics, instrumentation, and control systems from mechanical vibrations that could lead to malfunction or failure. Vibrations in aircraft can arise from engines, aerodynamic forces, and other factors, and if not properly managed, they can lead to fatigue and wear in key components, reducing the aircraft's operational lifespan.

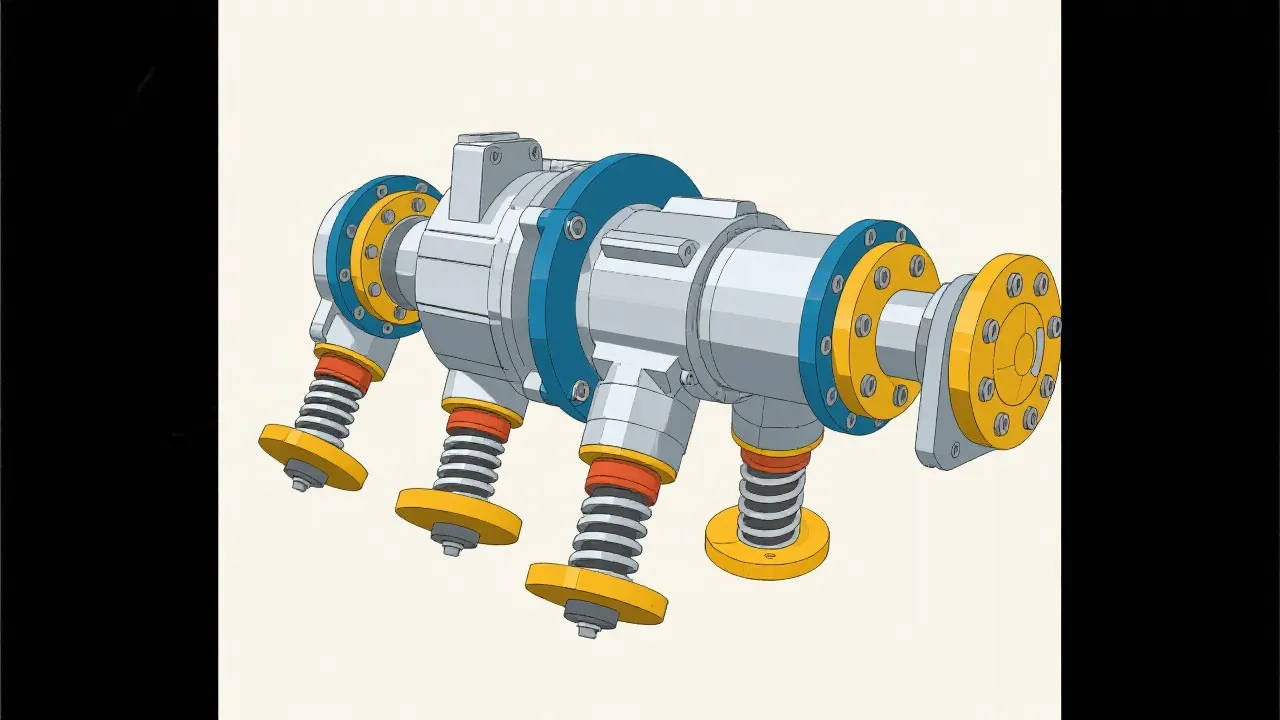

Aerospace vibration isolators are available in various types, each suited to different applications and environments. These include:

The choice of materials for aerospace vibration isolators is critical due to the demanding conditions of flight and the need for reliability. Common materials include:

Selecting the appropriate vibration isolators involves evaluating several factors, including:

| Type | Applications | Materials | Advantages |

|---|---|---|---|

| Elastomeric | General aviation, commercial aircraft | Rubber, neoprene | Cost-effective, efficient |

| Wire Rope | Military and high-performance aircraft | Stainless steel | Robust under extreme conditions |

| Metal Mesh | High-temperature applications | Metal wire mesh | High damping capacity |

| Active Control | Advanced military jets, civil aircraft | Sensors and actuators | Real-time adjustments, superior control |

| Foam and Composite | Commercial and private aircraft | Foam, composites | Lightweight, flexible damping |

The development and application of aerospace vibration isolators face several challenges, primarily due to the complexity and variability of the vibrational environment in aircraft. Advances in materials science and engineering continue to drive improvements in isolator performance, with a focus on reducing weight and size without compromising on effectiveness. Future prospects include the integration of smart materials and adaptive systems that can adjust to changes in vibration patterns during flight.

As the aerospace industry continues to innovate, engineers are exploring novel materials like shape memory alloys and piezoelectric materials that can provide more responsive damping solutions. Furthermore, advances in computational modeling allow for better predictions of vibrational behavior, improving the design of isolators before manufacturing.

In addition to these technological advancements, regulatory considerations are also becoming increasingly significant. Manufacturers must align their designs with stringent aviation standards and testing protocols, ensuring reliability and safety in demanding operational scenarios. Collaboratives and partnerships between academic institutions and industry leaders are fostering the research and development necessary to push these boundaries further.

The primary functions include minimizing vibrations to protect sensitive equipment, ensuring passenger comfort, and extending the lifespan of aircraft components. They also play a crucial role in enhancing the overall reliability of aircraft systems, thus contributing to safe flight operations.

Elastomeric isolators use rubber materials for damping, relying on elasticity and deformation to absorb vibrations. In contrast, wire rope isolators use coiled metal wires that provide superior damping capabilities in extreme conditions, making them suitable for military applications and high-performance environments.

Material selection is essential to ensure that isolators can withstand environmental conditions and perform effectively over a wide range of frequencies and loads. The right materials help in achieving the desired combination of strength, elasticity, thermal resistance, and durability necessary for aerospace applications.

Future developments are expected to focus on integrating smart materials and responsive systems that can adapt to real-time vibration conditions. The use of advanced computational methods for predictive analysis and testing protocols will also enhance the design of vibration isolators, paving the way for lighter, more effective solutions.

Examining real-world applications of aerospace vibration isolators provides valuable insights into their effectiveness and the benefits they deliver across various aircraft platforms. Below, we present a few notable case studies:

The Airbus A380 is renowned for its cutting-edge technology and passenger comfort features. One critical aspect of its design includes the implementation of advanced vibration isolators between the engines and the wing structure. The elastomeric isolators used in this aircraft were specifically designed to manage vibrations while simultaneously reducing noise transmission to the passenger cabin. This design consideration resulted in a significantly quieter and more comfortable flying experience, demonstrating the effectiveness of isolators in commercial aviation.

In military aircraft like the F-35, vibration control is vital due to the high operational speeds and complex maneuvers they perform. Wire rope isolators have been integrated into the structural framework and various onboard systems in the F-35 to manage the extreme vibrations experienced during combat and aerial maneuvers. These isolators not only protect sensitive avionics but also contribute to the aircraft's stealth capabilities by mitigating noise and vibrations that could betray its position.

During launch and re-entry, spacecraft like the Space Shuttle experience intense vibrations. To counteract these forces, NASA employed specially engineered isolators in various components, such as onboard instruments and control systems. The combination of high-damping elastomeric materials and metallic support structures allowed these systems to survive the rigors of launch while maintaining operational integrity. This case underscores the importance of vibration isolation in environments where traditional solutions may fail due to the extreme dynamic conditions.

Implementing effective vibration isolation solutions involves careful planning, rigorous testing, and ongoing maintenance. Here are some best practices:

In conclusion, aerospace vibration isolators are critical to the safe and efficient operation of modern aircraft. Their role in protecting sensitive systems, enhancing passenger comfort, and maintaining aircraft integrity cannot be overstated. As technology advances, the industry will continue to innovate, incorporating new materials and methods for vibration isolation that lead to even greater efficiency and reliability. These developments will not only improve aircraft performance but also pave the way for the next generation of aviation technology, contributing to a safer, quieter, and more sustainable future in flight.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!