Aerospace vibration isolators are crucial components in modern aviation, designed to absorb and reduce vibrations in aircraft systems. These isolators enhance the performance and lifespan of aviation equipment by minimizing structural stress and noise. Discover their significance, types, and applications, along with industry insights in this comprehensive guide.

Aerospace vibration isolators are pivotal in ensuring the efficient operation and longevity of aircraft components. By dampening vibrations, these isolators prevent wear and tear on both machinery and infrastructure, maintaining the integrity of sensitive aerospace equipment. This guide delves into the mechanics, types, and applications of these indispensable components in aviation. Understanding the crucial role of vibration isolators not only highlights their importance in existing aviation systems but also showcases the ongoing innovations aimed at enhancing aerospace technology.

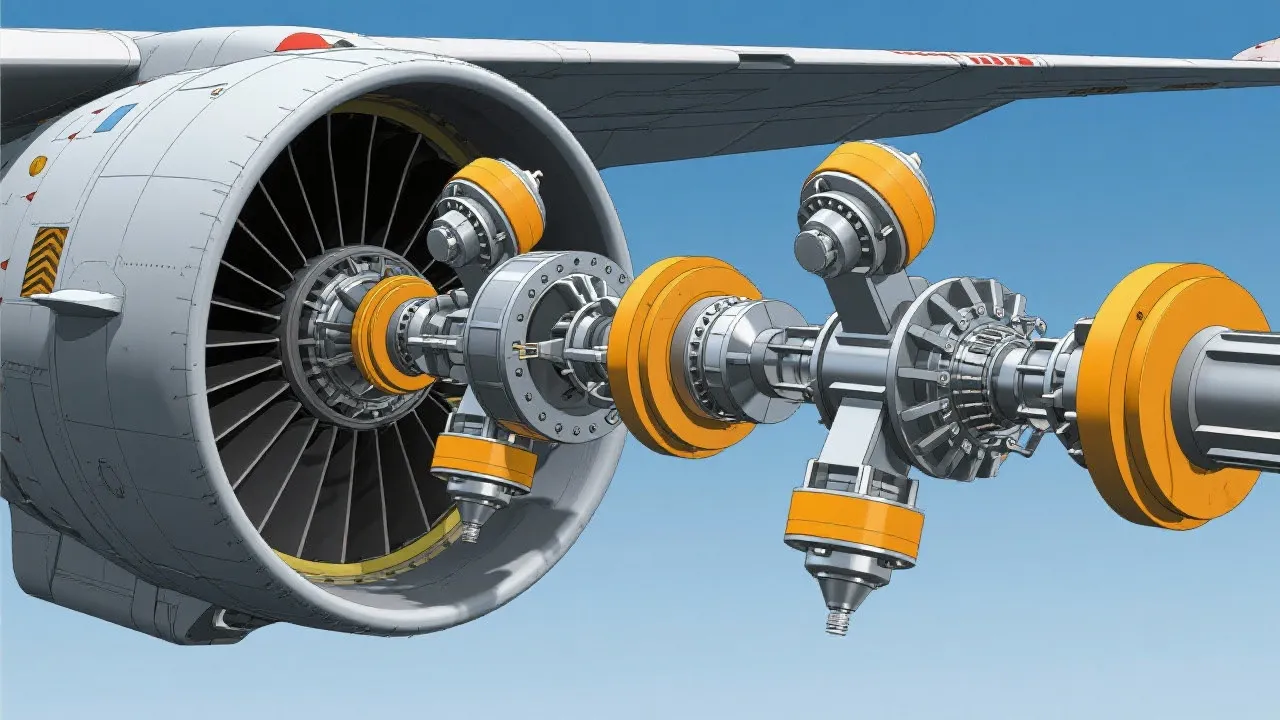

Vibration isolators function by converting kinetic energy from vibrations into heat energy, which is dissipated safely. This process shields equipment from continuous stress. Due to the high-frequency vibrations encountered in aerospace environments—stemming from aerodynamics and engine operations—effective isolation technology is crucial for operational stability and safety. The essential mechanics of vibration isolation rely on physical properties and advanced engineering principles that allow for the efficient management of forces and energy in motion.

In principle, vibration isolators operate on the foundation of mass-spring-damper systems. The isolator's components—including springs and damping materials—are strategically designed to absorb energy. The springs provide the resilient support needed to counteract external forces, while the damping materials, typically made from elastomers or other viscoelastic materials, dissipate energy through internal friction. This combination creates a system that can effectively reduce the amplitude of vibrations transmitted to sensitive equipment.

Moreover, the design of these isolators considers various factors, including the frequency of vibrations, amplitude, and load conditions. Advanced simulation techniques are employed during the design process to predict isolator performance under different scenarios, ensuring they can accommodate the diverse environmental conditions faced in aerospace operations. The balancing act between rigidity and flexibility makes choosing the right isolator critical for achieving optimal vibration isolation.

From engines and airframes to avionics and passenger accommodations, vibration isolators find multifaceted applications in the aerospace sector. In commercial aviation, these isolators are crucial in reducing noise and vibration levels in both the cockpit and passenger cabins. By ensuring minimal vibrations in cockpits, they enhance pilot comfort and control, allowing for more precise navigation and reducing fatigue during long flights.

In passenger areas, vibration isolators contribute to a smoother, quieter experience. Modern aircraft designs are focusing on passenger comfort, and isolators play a critical role in providing a tranquil environment by decreasing low-frequency noise that can be intrusive. This improved acoustics not only enhances passenger satisfaction but can also significantly contribute to overall cabin pressure management by reducing noise levels that may mask important warnings or notifications.

Aerospace vibration isolators are also indispensable in engineering contexts, where they are integrated into test facilities and simulators. In these settings, isolators maintain the precision testing conditions required for developing and validating new aircraft systems. For example, during vibration testing of new aircraft designs, it is essential to isolate the test model from external vibrations to accurately assess its structural integrity and performance under various flight conditions.

Moreover, research and development teams utilize advanced isolation setups to simulate real-world scenarios, enabling them to study how different design features influence overall aircraft behavior. The importance of this application cannot be overstated, as it allows engineers and designers to identify and rectify potential issues before they are implemented in actual aircraft, ultimately improving aviation safety and reliability.

Advancements in material sciences and engineering have spearheaded innovations in vibration isolation technology. The integration of smart materials, such as shape memory alloys and piezoelectric devices, is revolutionizing how isolation systems function. These materials can react adaptively to changing conditions, providing real-time adjustments to their damping properties based on detected vibrations. Such responsive systems enhance overall performance and improve adaptability to different operational scenarios, significantly benefiting aerospace functionality.

As sustainability becomes a central theme in aerospace design, the development of lighter, more efficient isolators promises to enhance fuel efficiency and environmental performance. This trend is evident in the increasing use of advanced composite materials, which can deliver high strength-to-weight ratios and offer greater resistance to fatigue compared to traditional materials. The drive for lightweight designs is not solely about enhancing fuel efficiency; it also translates into increased payload capacities and improved aerodynamic performance, which are critical factors in modern aircraft design.

Another emerging trend is the development of modular vibration isolation systems. These allow for easy replacement and upgrading of components without needing a full system redesign. Such flexibility can significantly reduce maintenance downtimes, improve system longevity, and reduce costs over time. This modular approach enables manufacturers to stay ahead in a rapidly evolving industry by incorporating the latest innovations into their existing systems with minimal disruption.

Furthermore, collaborations between universities, research institutions, and aerospace manufacturers drive much of the innovative research in vibration isolation technology. The focus on interdisciplinary approaches leverages expertise across fields such as materials engineering, structural dynamics, and computer modeling, fostering the development of next-generation isolators that can outperform traditional designs. These collaborative efforts aim to tackle the challenges posed by operating conditions in aerospace, including high-frequency and high-amplitude vibrations, ensuring that isolators continue to meet stringent industry standards.

Before vibration isolators are deployed in aviation applications, they undergo rigorous testing and certification processes to ensure their reliability and performance. Testing procedures are designed to simulate real-world operating conditions to confirm that isolators meet safety standards and performance criteria. Vibration tests typically involve subjecting isolators to controlled vibratory environments, allowing engineers to assess their behavior under various frequencies and amplitudes.

The certification process varies across different aerospace regulatory bodies, such as the Federal Aviation Administration (FAA) in the United States or the European Union Aviation Safety Agency (EASA). Manufacturers must demonstrate compliance with relevant standards such as DO-160, which specifies environmental conditions and test procedures for airborne equipment. This stringency ensures that only the most effective and reliable isolators are utilized in aviation, thereby upholding high safety and operational standards.

In addition to vibration testing, isolators are also evaluated for their durability, fatigue resistance, and environmental stability. These assessments are vital for ensuring that isolators can withstand the demanding conditions of flight, including temperature fluctuations, humidity, and exposure to various chemicals. By adhering to these rigorous testing protocols, manufacturers can provide confidence that their products will perform consistently throughout the lifespan of the aircraft.

Aerospace vibration isolators are integral to the maintenance of aircraft performance and safety. As the industry evolves, the innovation in isolator technologies continues to offer improved solutions that cater to the ever-demanding conditions of modern aviation. By leveraging advancements in materials, design, and engineering, vibration isolators enhance the overall safety and efficiency of aircraft operations. They not only contribute to the longevity and reliability of aircraft systems but also play a critical role in enhancing passenger comfort and operational efficiency. With ongoing research and technological advancements, the future of aerospace vibration isolators promises further enhancements and can significantly contribute to the overall sustainability of aviation.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!