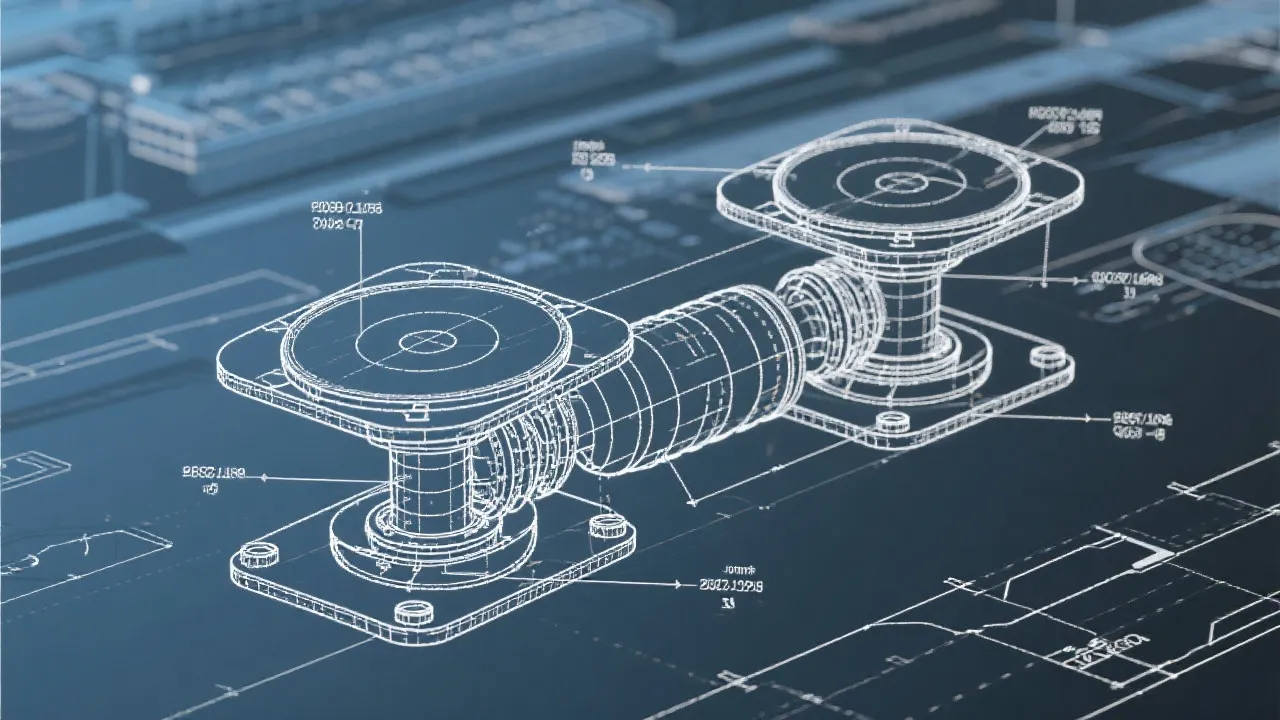

Aerospace vibration isolators are crucial components in the aviation and aerospace industries that mitigate unwanted vibrations, ensuring structural integrity and passenger comfort. These devices utilize advanced materials and engineering to minimize the transmission of vibrational forces from aircraft and spacecraft engines, contributing significantly to safety and efficiency.

In the high-stakes world of aerospace engineering, precision and reliability are pivotal. Aerospace vibration isolators play a vital role in this ecosystem by addressing the challenges posed by unwanted vibrations. By dampening and controlling these vibrational forces, these isolators enhance not only the structural integrity of aerospace vehicles but also the comfort and safety of passengers and crew. The need for effective vibration isolation systems has become increasingly important with the growing demand for more advanced, efficient aircraft and the need for safety in high-stress environments like space travel.

The primary function of aerospace vibration isolators is to absorb and effectively dissipate vibrational energies. These energies often originate from the engines and can otherwise propagate through the structure, leading to mechanical fatigue or damage. By mitigating these effects, isolators ensure the longevity and reliability of aircraft and spacecraft components. Without the application of these vital isolators, vibrations could resonate within the structure, potentially leading to catastrophic failures, decreased performance, and compromised safety protocols. Isolators, therefore, not only enhance the lifespan of aircraft systems but are also a critical component in meeting regulatory standards imposed by aviation authorities across the world.

Aerospace vibration isolators operate on principles of mechanical engineering and material science. Typically, they are made from specialized elastomers or metals tailored to specific vibration frequencies and amplitudes. The materials are selected based on their inherent damping properties and resistance to environmental factors, such as temperature extremes and chemical exposures typical in aerospace contexts. To achieve optimal performance, engineers perform extensive testing and simulations to ensure that isolators can handle the specific vibration profiles encountered in their intended applications. Advanced computational models help predict how isolators will behave under various operational stresses and conditions, enabling the development of robust solutions for complex aerospace applications.

The selection of materials for vibration isolators is critical. Common materials include rubber composites, silicone, and advanced polymer blends for applications requiring flexibility and thermal resistance. Metal, such as titanium or steel, can be used when strength and durability are prioritized over extreme weight considerations. Each of these materials comes with its own set of benefits and trade-offs. For example, while rubber compounds offer excellent damping properties and cost-effectiveness, they may not perform well in extreme temperature ranges compared to metal-based isolators. Conversely, metallic isolators can handle more significant loads and harsher environments but often increase the overall weight of the assembly, a critical factor in aerospace design where weight savings can significantly impact fuel efficiency and performance. Moreover, ongoing research into new materials, such as nanocomposites, promises to enhance the performance characteristics of isolators further.

These isolators are utilized in various aerospace applications, from commercial passenger jets to space exploration vehicles. In airplanes, isolators are crucial in engine mounts, reducing noise and protecting avionics systems from destructive resonance. In spacecraft, they provide essential protection against the intense vibrational forces encountered during launch and flight through the Earth’s atmosphere. For example, the rigorous conditions during rocket launches involve extreme vibration levels that can threaten the structural integrity of critical systems, hence making vibration isolators indispensable. They are also employed in sensitive instruments and payloads carried in space, including satellites and scientific devices, ensuring that vibrations generated by the launch vehicle do not affect the performance of these delicate systems. The importance of vibration isolators becomes increasingly magnified in advanced aerospace systems such as unmanned aerial vehicles (UAVs) and electric propulsion concepts, which incorporate various novel technologies necessitating refined vibration management.

| Solution Type | Material | Application Suitability |

|---|---|---|

| Rubber Isolators | Natural and synthetic rubber compounds | Cost-effective, ideal for moderate environments, and effective in vibration damping |

| Metal Spring Isolators | Titanium, Aluminum | High load-bearing capacity, suitable for harsh conditions, provides better durability |

| Composite Material Isolators | Advanced polymers and composites | Lightweight and robust, ideal for space applications and dynamic loading scenarios |

| Pneumatic Isolators | Air cushion systems | Used in applications requiring variable stiffness and often in research facilities or experimental vehicles |

| Active Vibration Control Systems | Electromechanical systems with sensors and actuators | Real-time adjustment to vibration profiles for enhanced damping in sophisticated systems |

As aerospace technology progresses, so does the innovation within vibration isolation solutions. Research and development are intensely focused on improving material performance and creating smart isolators that can adapt to changing environmental and operational conditions, further optimizing vibration control dynamically. These smart isolators utilize sensors to detect vibration levels and actuators to adjust their damping properties in real-time, ensuring optimal performance under varying circumstances. An example of these advancements is the exploration of piezoelectric materials, which can generate energy in response to mechanical stress and provide the potential for self-powered monitoring systems. This integration of technology into vibration isolation not only promises improved performance but also enhances the safety measures surrounding aerospace vehicles.

Despite the advancements being made in aerospace vibration isolators, several challenges persist. One primary concern involves the need for lightweight solutions that do not sacrifice performance. As the aerospace industry pushes toward more efficient designs and sustainable technologies, isolators must meet stringent weight requirements while still providing the necessary damping performance. Additionally, the challenge of maintaining performance over time in the harsh environments of space and aeronautical operations is significant. Engineers are tasked with ensuring that materials and designs can withstand prolonged exposure to temperature variations, UV radiation, and mechanical wear-and-tear without degradation.

Aerospace vibration isolators are devices designed to reduce the amplitude of vibrational energy in aircraft or spacecraft structures, safeguarding their structural integrity and operational efficiency. Their design and effectiveness are critical to ensuring the long-term performance of vital systems during operation.

By mitigating vibrational forces, these isolators contribute to reduced maintenance needs, improved longevity of components, and enhanced passenger comfort. They also play a role in noise reduction, which is critical for enhancing the overall passenger experience during flight.

Yes, isolators vary significantly, including rubber, metal, and composite types, each selected based on specific performance requirements and operational environments. Moreover, their application can differ greatly across various types of vehicles, such as commercial airliners versus military aircraft or space-bound systems.

Researchers are focusing on smart isolators equipped with sensors and real-time adjustment capabilities, utilizing advanced materials and designs to address specific vibration profiles. There are also ongoing efforts to reduce the weight of these isolators while maintaining their effectiveness, as well as exploring new materials such as nanocomposites and bio-inspired materials.

Absolutely. By extending the life of components and preventing mechanical damage due to vibrations, isolators can help reduce the overall maintenance costs of aircraft and spacecraft. Effective vibration control contributes to fewer unscheduled repairs and longer intervals between maintenance checks.

The evolution and continuing development in aerospace vibration isolators are a testament to their significance in the aerospace domain. They are not just components, but pivotal elements that drive the safety, reliability, and efficiency of modern aerospace vehicles. Adopting advancements in this field promises a future where aerospace vehicles can be lighter, faster, and even more resilient than ever before. The push for enhanced performance and lower operational costs mandates an unwavering focus on innovation in vibration isolation solutions, making this an exciting time to be a part of the aerospace engineering field. As technology evolves and integrates with aerospace systems, vibration isolators will continue to play a crucial role in shaping the future of flight and space exploration.

Looking forward, several key areas warrant further research and development in the field of aerospace vibration isolators. One is the exploration of self-healing materials, which can recover their structural integrity after experiencing damage, potentially prolonging the lifecycle of isolators significantly in harsh environments. Another promising direction is the integration of advanced computational techniques like machine learning and artificial intelligence, which could predict failures and optimize the performance of vibration isolation systems in real-time based on operational data. Furthermore, as electric and hybrid propulsion systems become more prevalent, researchers must consider how different vibration signatures can impact these systems to ensure proper design of isolation solutions applicable to these new technologies.

To ensure the effectiveness of vibration isolators, rigorous testing and validation protocols are essential. This includes simulations that replicate the anticipated operational conditions, as well as physical testing using prototype isolators under controlled conditions. Industry standards play a significant role in guiding these testing processes, but advancements in sensor technology can enhance the reliability of results by providing real-time feedback. Continuous improvement in testing methodologies will help engineers develop isolators that not only meet current demands but also anticipate future challenges posed by emerging aerospace technologies.

In sum, aerospace vibration isolators are a crucial aspect of aerospace engineering, contributing significantly to the safety, comfort, and performance of aircraft and spacecraft. As the industry continues to innovate and push boundaries, the challenge will be to enhance the capabilities of these isolators while meeting new standards for sustainability and efficiency. By focusing on advancements in materials, technology integration, and predictive modeling, the future of aerospace vibration isolation looks promising. Ensuring that these devices continue to evolve in line with the cutting-edge developments in aerospace technology will be crucial to achieving higher levels of performance and safety in the skies and beyond.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!