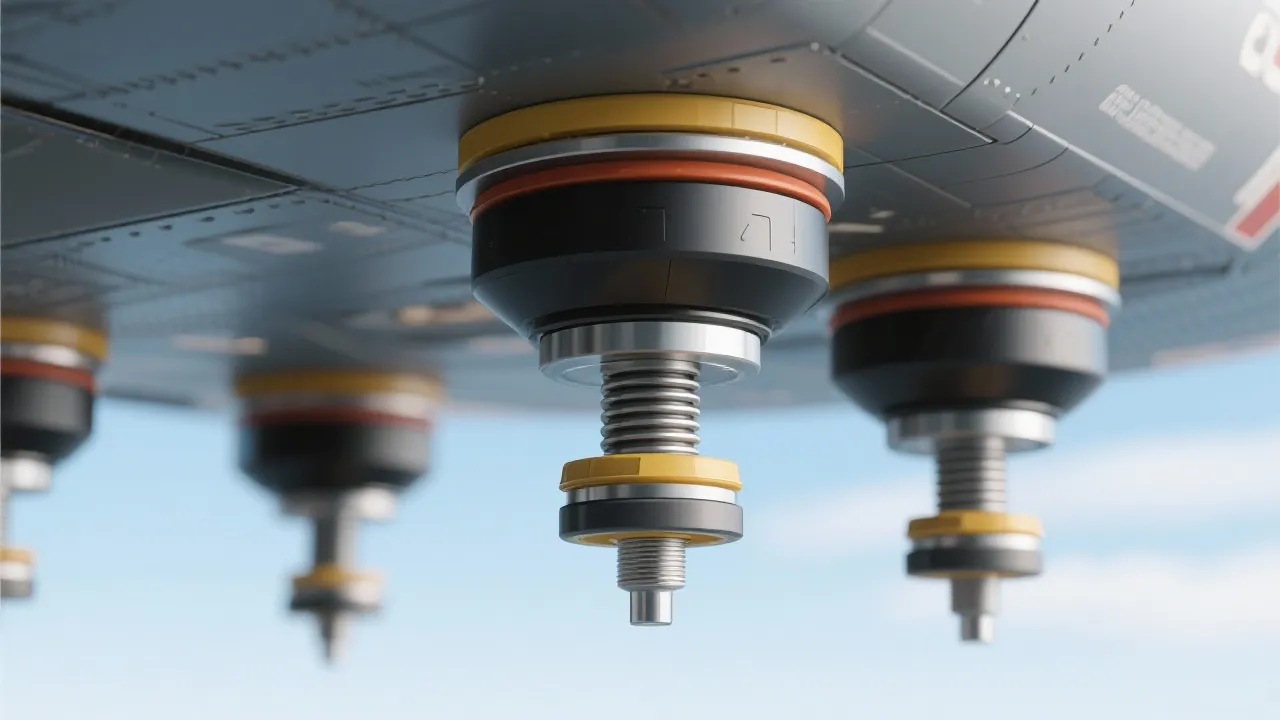

This article provides a comprehensive exploration of aerospace vibration isolators, highlighting their significance in minimizing structural vibrations within aircraft and spacecraft. These components are crucial for ensuring the longevity and functionality of aerospace systems by protecting sensitive equipment from potential damage caused by vibrational forces.

Aerospace vibration isolators are vital components in the aviation and spacecraft industries, designed to mitigate vibrations that can affect the performance and safety of various systems. In environments where precision and reliability are paramount, these isolators play a critical role in maintaining equipment integrity and enhancing the overall operational lifespan. The importance of vibration control in such specialized domains cannot be overstated, as the impact of vibrations poses significant risks, not only to equipment but also to the safety of crew and passengers onboard aircraft, as well as the success of space missions.

Vibration in aerospace applications arises from numerous sources, such as engine operations, aerodynamic forces, and mechanical movements. These disturbances can lead to resonance, particularly in lightweight structures where the materials used are sensitive to dynamic stressors. If left unaddressed, these vibrations can lead to fatigue, material failure, or even catastrophic system failures. An effective vibration isolation system reduces the transmission of energy through components and systems, allowing sensitive instruments to function correctly without interference. Aerospace vibration isolators are engineered to absorb these vibrations; they provide essential stabilization, thereby minimizing their impact on sensitive instruments and machinery. Moreover, the degradation of structural integrity over time due to constant vibrations can result in expensive maintenance and repairs, making the investment in robust isolators worthwhile.

These isolators are crafted with precision and incorporate advanced materials that offer durability and reliability. Key features include:

Aerospace vibration isolators are utilized across various applications, including:

The materials used in aerospace vibration isolators must meet stringent standards to handle the demanding conditions of flight. Common materials include rubber compounds, elastomers, and specialized metallic alloys, each offering a unique set of properties tailored to specific isolation requirements.

Among these materials, natural rubber offers good elasticity and damping properties, making it effective for a range of isolation tasks. Silicone rubber is also selected for its durability over a wide temperature range, providing reliable performance in extreme conditions. For applications requiring higher strength, metallic springs combined with damping materials can provide superior vibration control. Moreover, advancements in polymer blending have led to the development of composite materials that offer enhanced damping capabilities, which are beneficial especially in high-frequency vibration mitigation.

Furthermore, aerospace manufacturers are increasingly leveraging advanced materials such as carbon fiber composites and thermoplastic elastomers. Carbon fiber composites are noted for their lightweight properties while maintaining high strength. This is essential for aerospace applications where every gram contributes to fuel efficiency and performance. Thermoplastic elastomers enhance the durability and lifespan of isolators by allowing for better resistance to environmental factors that can degrade traditional materials.

Precision in manufacturing is essential to the production of effective vibration isolators. The process typically involves:

The integration of automation in manufacturing processes, including robotics for assembly and quality control, has significantly enhanced the consistency and precision of isolators being produced. Additionally, the trend towards additive manufacturing is starting to impact the design of isolators, allowing for more complex geometries that traditional manufacturing methods may struggle to achieve.

| Type | Description |

|---|---|

| Passive Isolators | Utilize basic mechanical components like rubber or foam to absorb vibrations regardless of the frequency, suitable for standard applications where dynamic response is not critical. |

| Active Isolators | Feature sophisticated feedback control systems and sensors to adapt to varying vibrational frequencies, making them ideal for sensitive equipment that requires real-time adjustments to maintain stability. |

| Hybrid Isolators | Combine features of both passive and active isolators, offering versatile vibration control solutions that can adjust to different conditions while providing a baseline of isolation. |

Despite advances, challenges remain in designing isolators that effectively perform across a broad temperature range and in variable gravitational forces. Variability in vibrational characteristics from different sources, such as engine vibrations and environmental turbulence, requires isolators that can dynamically adjust their properties while maintaining energy absorption. Continuous innovations are being pursued to improve material resilience and adaptive functionalities.

One of the most significant challenges lies in the dynamic behavior of materials under high-frequency vibrations. As aircraft and spacecraft are subjected to increased speeds, the frequency of vibrations can rise significantly, necessitating isolators that offer effective attenuation across a wider spectrum. Mechanical resonances can cause significant issues if not properly controlled, which leads manufacturers to seek new designs that mitigate or prevent these resonances.

Another notable challenge is the aging of materials. Prolonged exposure to environmental conditions, such as ultraviolet light or high ozone levels encountered in flight, can lead to degradation. Therefore, ongoing research is focused on developing newer materials with enhanced resistance to such conditions, which will lead to longer-lasting and better-performing isolators.

As aerospace technology continues to progress, the focus shifts towards developing smarter, more adaptable isolators. The integration of sensor technology and the Internet of Things (IoT) could offer real-time monitoring and dynamic adjustments, further securing aerospace missions and extending equipment service life. The concept of predictive maintenance is also making its way into the aerospace industry, where data analytics can inform when an aircraft component may fail, thereby enabling timely interventions.

Another avenue of innovation is the development of self-healing materials, which could address wear and tear issues commonly faced in isolators. Research is ongoing into materials that can repair themselves when damaged, significantly enhancing component longevity and reducing maintenance overhead.

Furthermore, advancements in artificial intelligence (AI) may lead to bespoke vibration isolation solutions that tailor responses based on historical vibrational data, environmental conditions, and specific mission parameters. This kind of adaptive technology will ensure vibration isolators remain aligned with the evolving demands of modern aerospace systems, improving not just the safety and effectiveness of aircraft but also contributing to more fuel-efficient designs.

Aerospace vibration isolators are integral to maintaining the functionality and safety of aerospace vehicles. Their ability to absorb and dissipate vibrational energy ensures that critical systems operate without disruption. As technology evolves, these components will likely see even greater sophistication and adaptability, effectively meeting the challenges of future aerospace endeavors. Continuous investment in research and development will not only lead to the creation of advanced materials and designs but will also foster innovation that enhances overall mission success in aviation and space exploration. With each iteration, the commitment to safety and efficiency remains at the forefront, reflecting the aerospace industry’s dedication to pushing the boundaries of what is possible.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!