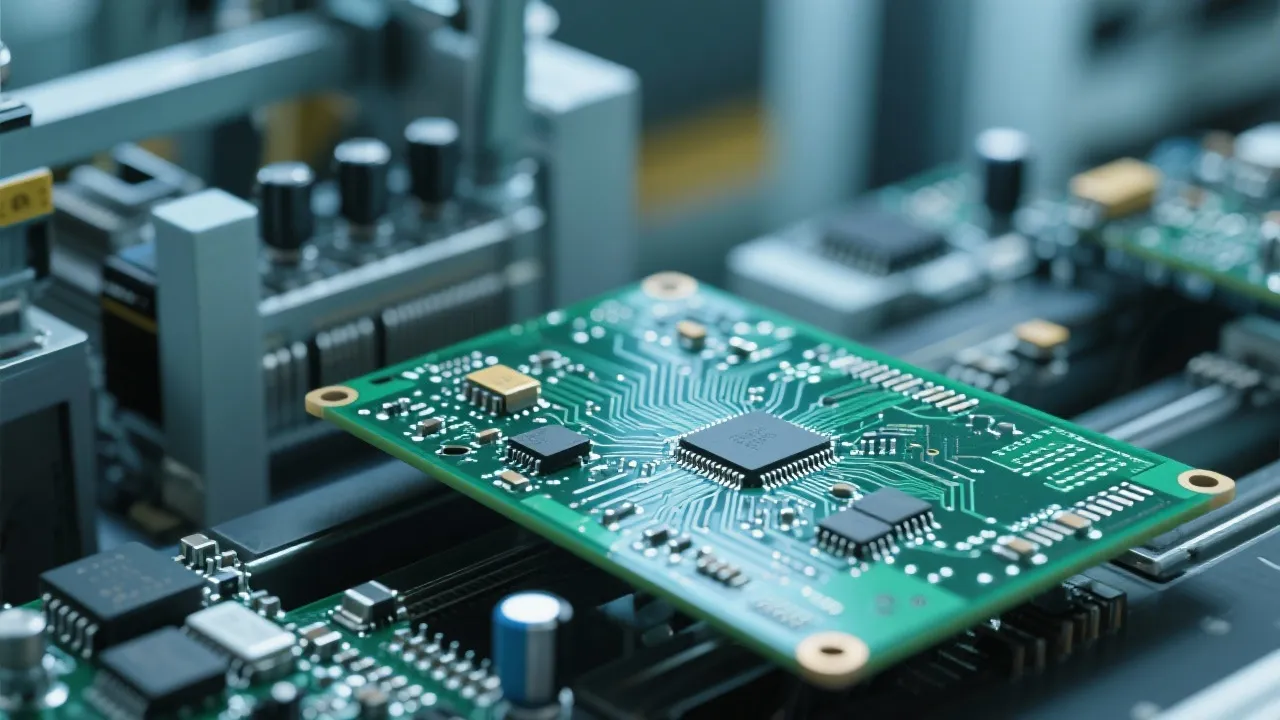

This comprehensive guide dives into the world of Jac Pcd, a specialized component in the electronics industry, known for its role in enhancing device functionality. Jac Pcd stands as a testament to technological advancement, often integrated into complex electronic systems due to its efficiency and reliability. This analysis provides insight into its applications, benefits, and why it's a choice component among manufacturers.

The evolution of electronics has brought forth various components that significantly impact device performance and reliability. Among these is Jac Pcd, a prevalent choice in the industry for its unparalleled precision and efficiency. Jac Pcd, known for its application in high-quality electronic assemblies, enhances device functionality through its unique properties. This article provides a comprehensive look into Jac Pcd, exploring its applications, benefits, and its positioning in the global electronics market.

Jac Pcd refers to a component used extensively in electronic circuit designs. It is renowned for its durability, thermal stability, and ability to withstand harsh environmental conditions. Jac Pcd is often utilized in applications requiring high precision and reliability, making it a favored choice for manufacturers striving for excellence in their electronic devices.

This component is designed to operate optimally under various operational stresses, thereby increasing the product's lifespan in which it is integrated. The precision engineering of Jac Pcd allows for minimal disruption in electronic signals, leading to enhanced performance and user satisfaction.

Moreover, Jac Pcd’s design enables seamless integration with various electronic systems, ensuring compatibility and functionality across different device platforms. Its versatility extends to various fields, making it a crucial player in the advancement of technology.

So, what makes Jac Pcd a preferred choice for manufacturers? It is primarily its reliability and performance enhancement capabilities. It supports the seamless transmission of signals while being resistant to high temperatures and electrical interference. These features contribute to a smoother operation and extended lifespan of devices. Additionally, Jac Pcd components often require less maintenance, saving costs in the long run for both manufacturers and end-users.

Jac Pcd also presents advantages in terms of weight reduction in electronic designs, which is increasingly important in consumer electronics and automotive applications where weight plays a critical role in performance and energy efficiency. By reducing the overall weight of electronic assemblies, manufacturers can create lighter and more efficient devices, contributing to better fuel efficiency in vehicles and improved ergonomics in handheld gadgets.

Additionally, the biocompatibility of Jac Pcd materials makes them especially valuable in medical applications, as they can be safely used in contact with biological tissues. This property opens the door to innovations in medical device designs, enabling the development of safer and more effective patient care solutions.

Manufacturing processes integrating Jac Pcd are sophisticated. Precision engineering and state-of-the-art technology ensure each component meets strict quality and performance standards. The production environment must be impeccably controlled, and components are tested rigorously to guarantee optimal performance.

Implementing Jac Pcd in manufacturing involves several steps:

1. Design and Specification: Detailed specifications determining the component's functional requirements are developed, including dimensions, thermal properties, and electrical characteristics.

2. Material Sourcing: High-quality materials are sourced for producing the reliable Jac Pcd components. Suppliers are vetted to ensure compliance with industry regulations and standards.

3. Fabrication: Advanced machinery precisely fabricates the components to meet detailed specifications, incorporating processes such as CNC milling, laser cutting, and molding technologies.

4. Quality Testing: Each Jac Pcd component undergoes stringent testing to ensure it surpasses industry standards before being approved for use. Tests typically involve thermal cycling, vibration resistance, and electrical integrity assessments.

Furthermore, the integration of automation and robotics in Jac Pcd manufacturing significantly enhances productivity and reduces human error. Automated systems can efficiently handle tasks such as assembly, inspection, and packing, ensuring consistency and quality across batches of components. These advancements in manufacturing processes not only streamline operations but also contribute to a more sustainable approach by minimizing waste and energy consumption.

| Industry | Benefits of Jac Pcd |

|---|---|

| Consumer Electronics | Enhances functionality, durability, and longevity of devices. |

| Industrial Equipment | Improves efficiency and reliability in demanding environments. |

| Automotive Systems | Increases sensor accuracy and system reliability. |

| Medical Devices | Ensures precision and safety in medical diagnostics. |

| Aerospace Applications | Provides weight savings and withstands extreme conditions for enhanced performance. |

Q: Why is Jac Pcd favored over other components?

A: Jac Pcd is favored due to its stability, durability, and ability to enhance device performance even under adverse conditions.

Q: What are the primary challenges in manufacturing Jac Pcd components?

A: The challenges include maintaining precision in manufacturing, ensuring quality control, and sourcing premium materials. Additionally, adapting to new technologies and manufacturing techniques to keep up with industry demands poses continual challenges for manufacturers.

Q: How does Jac Pcd contribute to the sustainability of electronic devices?

A: By offering enhanced durability and reducing the need for frequent replacements, Jac Pcd contributes to the sustainability of devices, reducing electronic waste over time. Its longevity minimizes the environmental impact associated with product disposal and production, further solidifying its role in eco-friendly electronics development.

Q: Can Jac Pcd be recycled?

A: Yes, Jac Pcd materials are often recyclable. As recycling processes and technologies improve, there is an increasing focus on recovering and repurposing electronic components, including Jac Pcd, to promote a circular economy in the electronics industry.

In conclusion, Jac Pcd stands as a cornerstone in modern electronics, offering reliability and superior performance characteristics critical for technological advancement. As industries continue to demand robust and efficient components, Jac Pcd will undoubtedly remain integral to reaching future advancements in electronic design and functionality. The rising trend toward sustainability will further cement its importance, as manufacturers seek components that not only provide top-notch performance but also contribute positively to our environmental footprint.

As the electronics landscape evolves, researchers and engineers are also exploring new materials and technologies that build upon the foundational benefits of Jac Pcd. Innovations such as biodegradable electronic materials and smart components that can self-assess their performance and health may emerge, pushing the boundaries of what is currently possible in electronic design.

Furthermore, with the integration of Internet of Things (IoT) technology in devices, the role of Jac Pcd in enhancing connectivity, functionality, and data transmission will become even more pronounced. As devices become more interconnected, the demand for reliable and high-performance components will only increase, ensuring that Jac Pcd retains its pivotal role in the future of electronics.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!