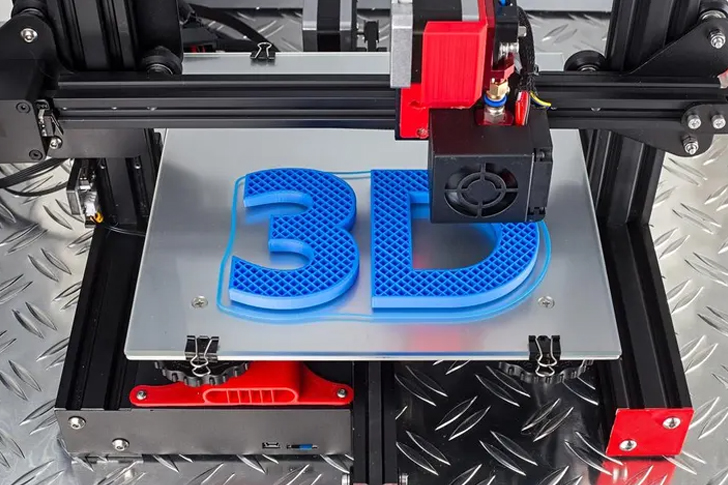

Understanding and managing your 3D printing materials cost is crucial for efficient and budget-friendly 3D printing operations. This guide offers actionable advice and essential tips for reducing costs.

To manage 3D printing materials cost effectively, you need to understand the different types of materials available and their associated costs. Here are some common materials:

Selecting the very cost-effective material that meets your project requirements is key:- Opt for PLA for general-purpose printing when strength and flexibility are not critical.- Use ABS for more durable items but be prepared to handle its printing challenges.- Consider PETG for a combination of durability and ease of use.

Efficient use of material can significantly reduce your costs:-

A well-maintained printer will produce better quality prints, reducing waste:- Regularly clean and lubricate moving parts.- Calibrate your printer often to ensure dimensional accuracy.- Ensure the print bed is level to avoid warping and failed prints.

Purchasing materials in larger quantities usually results in cost savings:- Very suppliers offer discounts on bulk purchases.- Look for deals and discounts during sales or from suppliers offering loyalty programs.

Improper storage can degrade materials, leading to wasted prints:- Keep filament in airtight containers with desiccant packs to prevent moisture absorption.- Store resin in cool, dark places to extend its shelf life.

Recycling can significantly lower your 3D printing materials cost:- Use failed prints and excess filament to create new spools using a filament recycler.- Many companies offer recycling programs for used resin bottles and cartridges.

Reducing design costs also impacts your overall expenses:- Leverage affordable and open-source design repositories like Thingiverse or MyMiniFactory.- Customizing existing designs can save time and material versus creating completely new models.

Reducing the energy consumed during printing also lowers overall costs:- Print at lower temperatures when possible, as this reduces energy consumption.- Shorter print times also mean less electricity used.

Keep an eye out for additional ways to save:- Join online forums and communities to share tips and resources.- Consider used or refurbished equipment and materials.

Managing 3D printing materials cost involves selecting the right material, optimizing print settings, proper maintenance, and smart purchasing practices. By following these tips, you can significantly reduce your 3D printing expenses while maintaining high quality. Reducing waste and recycling not only helps in cost management but also contributes to a more sustainable practice. Stay informed and make strategic choices to keep your 3D printing projects efficient and cost-effective.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!