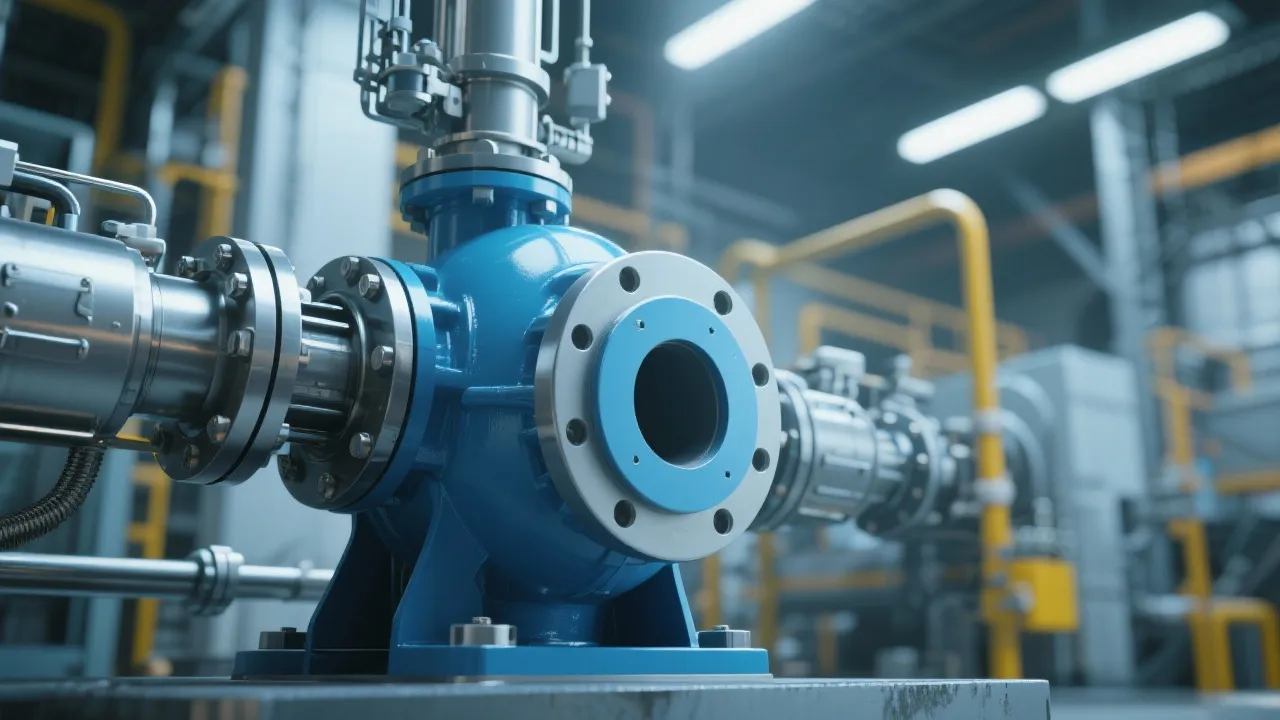

KSB's Wk series pumps are engineered for excellence in industrial liquid handling, integrating state-of-the-art design with robust materials for durability and efficiency. As a global leader in pump manufacturing, KSB delivers innovative solutions for various sectors, focusing on meeting diverse needs with precision and reliability.

The KSB Wk series pumps represent a pinnacle of engineering excellence in industrial pumps, designed to cater to diverse applications across various sectors. These pumps are renowned for their robust construction, efficient performance, and adaptability, making them a preferred choice for industries that require reliable liquid handling solutions. Their extensive design and engineering are the results of decades of experience and innovation in pump technology, ensuring they meet the demanding needs of modern industries. As part of KSB's trusted portfolio, the Wk series integrates advanced hydraulic principles with modern materials technology to provide a superior pumping solution that stands the test of time.

KSB, a global leader in pump manufacturing, has a reputation for delivering high-performance products that excel in challenging environments. The Wk series is engineered with precision to ensure low operational costs, minimal maintenance, and superior efficiency. These pumps are crafted using high-quality materials that enhance longevity and resistance to wear and tear, ensuring they can withstand the very demanding conditions. In addition to their robust construction, the Wk series incorporates innovative design features aimed at enhancing performance. Features such as optimized impeller geometry contribute to improved flow rates and energy efficiency. This attention to detail ensures that choosing KSB Wk series pumps translates to substantial long-term savings in terms of both energy consumption and maintenance efforts.

The versatile design of the Wk series enables their use in a wide range of applications, including water supply, wastewater management, and chemical processing. Their ability to handle various fluids, from potable water to corrosive chemicals, makes them indispensable in sectors such as agriculture, municipal services, and industrial manufacturing. The series is especially valued in settings where uninterrupted operations are crucial, such as power plants and large-scale industrial facilities. Additionally, the Wk series finds applications in HVAC systems, mining operations, and oil and gas industries, demonstrating the breadth of its applicability. This versatility allows plant managers and engineers to implement a single pump series across various operations, simplifying maintenance and procurement processes.

| Model | Capacity | Max Pressure | Material | Application |

|---|---|---|---|---|

| Wk 1.0 | 1000 m3/h | 16 bar | Stainless Steel | Water Supply |

| Wk 2.0 | 2000 m3/h | 20 bar | Cast Iron | Chemical Processing |

| Wk 3.0 | 3000 m3/h | 25 bar | Alloy Steel | Wastewater Treatment |

| Wk 4.0 | 1500 m3/h | 18 bar | Polypropylene | Food Processing |

KSB's Wk series pumps are available through an extensive network of authorized suppliers. Prices may vary based on model specifications, configurations, and market demands. It's advisable to contact local distributors for detailed price quotes and potential customizations tailored to specific project requirements. Additionally, many suppliers offer installation services and support, which can be invaluable in ensuring that the pumps are correctly integrated into existing systems. Furthermore, when considering the total cost of ownership, it’s worth considering not just the initial purchase price but also the operational efficiency and maintenance costs associated with each model over its lifetime.

In real-world settings, the KSB Wk series pumps have demonstrated their efficacy and reliability in numerous projects across various industries. One notable application is in the municipal water supply sector, where the ability to transport large volumes of potable water efficiently is crucial for community health and safety. In these settings, Wk series pumps are used to boost water pressure, ensuring consistent flow rates to homes and businesses.

In wastewater management, KSB Wk pumps play an essential role in transporting sewage and effluent to treatment facilities. Their robust construction handles varying waste compositions and the challenging environmental conditions typically found in these settings. Utilizing the Wk series ensures that municipalities can manage wastewater streams effectively, reducing the risk of overflow and contamination, thus safeguarding public health.

Moreover, in chemical processing, these pumps are instrumental in transferring aggressive fluids that can erode ordinary materials. Models constructed from specialized alloys or corrosion-resistant plastics are designed to handle these scenarios, maintaining operational integrity and reliability even when processing harsh chemicals. By selecting the appropriate model, businesses can enhance operational efficiencies and reduce the likelihood of equipment failures.

The modern industrial environment necessitates not just efficiency and reliability, but also a commitment to sustainability. The KSB Wk series pumps are designed with environmental impact in mind, incorporating energy-efficient technologies that contribute to reduced carbon footprints. By optimizing energy usage and minimizing waste, the pumps align with global standards for sustainable industrial practices.

Furthermore, the use of materials that can last longer and resist wear contributes to less waste in the long term. Durable materials reduce the frequency of replacements, leading to fewer manufacturing processes and decreased material consumption. KSB actively promotes recycling initiatives, encouraging the proper disposal of any obsolete pumps, which reflects their commitment to environmental stewardship.

KSB continues to invest in research and development to push the boundaries of what is possible with the Wk series pumps. Efforts are underway to integrate advanced monitoring systems, which would allow operators to continuously track performance and predict maintenance needs proactively. This predictive maintenance capability minimizes unexpected downtime and extends the life of the pumps.

Additionally, there is a growing focus on integrating smart technologies, including IoT (Internet of Things) capabilities, into the pumps. This would enable seamless communication with control systems, allowing for real-time optimization of pump operations based on changing demands and conditions. As industries become more interconnected, the ability for pumps to communicate with other machinery and systems will be paramount in achieving higher efficiency levels and reduced operational costs.

The KSB Wk series stands out as a versatile and robust solution for industrial liquid handling needs. Its combination of efficiency, durability, and adaptability positions it as a leader in the pump industry. Whether for large-scale applications or specialized needs, the Wk series is designed to deliver reliable performance where it matters very much. As industries evolve and face new challenges, the Wk series will undoubtedly play a pivotal role in shaping the future of fluid management, paving the way for innovations that further enhance productivity and sustainability in industrial operations.

Feedback from users of KSB Wk series pumps often highlights their exceptional performance and reliability. For instance, a manager at a large municipal water service remarked, "Since integrating the KSB Wk pumps into our operation, we've seen a dramatic reduction in energy costs and a significant improvement in flow consistency across our pipeline system. The robustness of the pumps has translated into fewer service disruptions, which has been invaluable for maintaining service levels to our community."

Similarly, a chemical processing plant supervisor stated, "The Wk series pumps have proven to be a game changer for our operations. We deal with highly corrosive fluids, and the specialized materials used in these pumps have offered us unparalleled durability. We've minimized downtime significantly, and the energy savings have had a positive impact on our overall operational costs." This type of positive feedback reflects the commitment KSB has to customer satisfaction and the high standards of quality they uphold in their pump solutions.

As we look towards the future, the world of pump technology will continue to evolve in response to changing industrial demands and environmental challenges. Innovations in materials science may soon lead to even more resilient pumps, capable of handling a wider range of fluids and conditions than ever before. Additionally, advancements in robotics and automation can redefine maintenance practices and reduce the labor costs associated with upkeep.

The KSB Wk series is already paving the way for smarter, more responsive pump technologies that not only meet but exceed industry expectations. The incorporation of AI-driven analytics into pump operation systems could revolutionize how industries approach fluid management, leading to unprecedented efficiencies and sustainability practices.

Throughout its operation, KSB has consistently placed a strong emphasis on customer support. Understanding that the performance of its products is just one facet of user experience, KSB has developed a dedicated team focused on ensuring clients have access to the information and assistance they need. From initial inquiries about the right pump model to ongoing support with installation and maintenance, the KSB customer service team is poised to assist every step of the way.

This emphasis on customer service extends to comprehensive training for staff on using and maintaining KSB Wk pumps effectively. Training sessions can be organized on-site or remotely to cater to the needs of every client. Such training not only enhances employee confidence in using the equipment but also contributes to the overall safety and efficiency of operations.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!