The ZL4460, an advanced industrial component, is integral to modern machinery systems, ensuring efficiency and precision. This article delves into its technical specifications, applications, and potential benefits for industries seeking enhanced operational performance. Discover how the ZL4460 can transform your manufacturing processes with its cutting-edge technology and innovative design features.

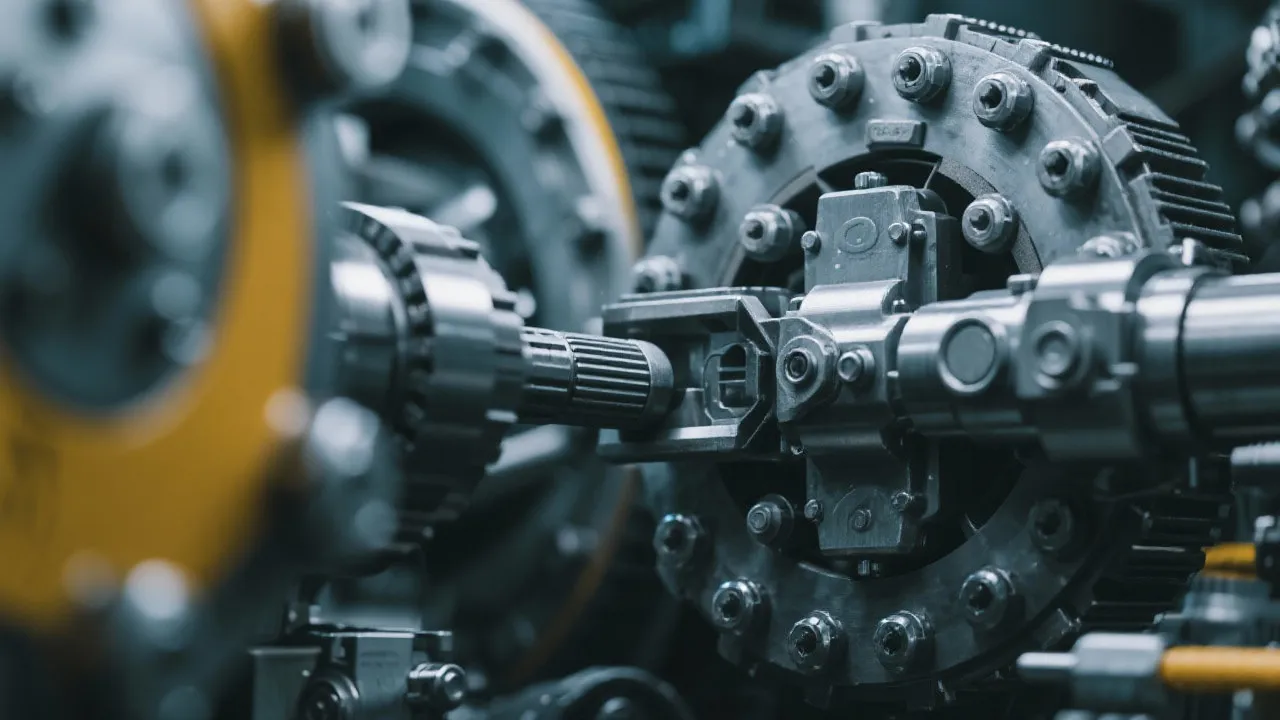

In the world of industrial machinery, precision and efficiency are paramount. The ZL4460 system has emerged as a groundbreaking component, playing a crucial role in advancing these two critical factors. With the ever-increasing demands of modern industries, the ZL4460 offers a level of performance that helps balance productivity with reliability. But what exactly is the ZL4460, and how does it integrate into the larger landscape of industrial technology?

The ZL4460 is not merely a mechanical part; it embodies a sophisticated blend of technology designed to respond dynamically to varying operational demands. This system is built on innovation, combining advanced sensors, computational algorithms, and integration capabilities that enhance overall system performance. As industries face mounting pressure to increase output while minimizing waste, the ZL4460 serves as a beacon of innovation, guiding organizations toward achieving their operational goals more effectively.

The ZL4460 system is characterized by its robust design and versatile functionality. It is crafted to withstand harsh industrial environments while maintaining optimal performance. Key technical specifications include a high tolerance limit, superior thermal efficiency, and adaptive load management. These features combine to make the ZL4460 a preferred choice for industries aiming to minimize downtime while maximizing productivity.

In addition to its standout features, the ZL4460 is equipped with an advanced data analytics module. This module allows for real-time monitoring of performance metrics and system health, essential for industries that rely heavily on predictive maintenance. By aggregating and analyzing data, the ZL4460 enables technicians to identify potential issues before they escalate into costly downtimes, providing invaluable support to maintenance teams.

| Features | Specifications |

|---|---|

| Durability | Constructed from high-grade materials, ensuring longevity under strenuous conditions. |

| Efficiency | Offers advanced power management and energy-saving capabilities. |

| Versatility | Compatible with a variety of industrial systems for diverse applications. |

| Real-Time Monitoring | Features an analytics module for performance tracking and maintenance alerts. |

| Adaptability | Seamlessly integrates with existing systems, minimizing the need for overhaul. |

The adaptability of the ZL4460 makes it suitable for a wide range of applications across industries. It is particularly advantageous in environments where precision and rapid throughput are vital. Common applications include manufacturing, automation, and even in the realms of aerospace technology. Each application benefits uniquely from the ZL4460’s ability to streamline operations and enhance system integrations.

In manufacturing, the ZL4460 can be applied to assembly lines where synchronization between various processes is critical. Its ability to communicate and coordinate with other machinery ensures that manufacturing workflows are optimized, reducing bottlenecks that can hinder productivity. In automation settings, it enhances robotic systems, allowing for greater precision in tasks such as welding, painting, and assembly.

When delving into aerospace technology, the ZL4460 proves invaluable due to its high reliability standards. Aerospace components must adhere to stringent safety and performance regulations, making the ZL4460's design and functionality particularly relevant. Its precision and adaptability are also critical in sectors such as aviation maintenance, where the efficiency of diagnostic systems can significantly affect turnaround times and reduce operational costs.

Integrating the ZL4460 into your existing machinery infrastructure offers numerous benefits. Firstly, it delivers substantial improvements in operational efficiency. This translates into reduced energy consumption and lower operational costs. Moreover, its advanced monitoring capabilities enhance predictive maintenance strategies, thereby prolonging equipment lifespan and reducing unexpected failures.

Secondly, users often report improved safety metrics when employing the ZL4460. With its ability to continuously monitor system parameters, potential hazards can be detected and addressed proactively. This capability is essential, particularly in high-risk environments where equipment malfunctions can lead to severe accidents or catastrophic events.

Additionally, businesses experience a boost in their Return on Investment (ROI) by leveraging the ZL4460’s features. Through improved efficiency and minimized downtime, organizations can focus on expanding their operations rather than expending resources on repairs and maintenance. This financial edge is vital for companies looking to remain competitive in rapidly changing markets.

Experts in the field of industrial manufacturing have noted the ZL4460’s contribution to improving production line capabilities. According to a report by Industry Week, the integration of such advanced machinery components is critical in the current landscape, where the focus is increasingly on sustainability and digital transformation. The ZL4460 supports these trends by providing a seamless interface between traditional manufacturing processes and modern digital frameworks.

Furthermore, industry analysts have observed that the ZL4460 aligns well with the growing trend of smart factories, where interconnected devices work cohesively to optimize production processes. The increase in digital transformation initiatives has highlighted the need for systems like the ZL4460 that can not only integrate with existing machinery but also enhance inter-machine communications.

In an era of manufacturing 4.0, where the Internet of Things (IoT) is reshaping traditional production methods, the ZL4460 stands out as a robust solution. It provides stakeholders with essential data insights that aid in decision-making processes. This capability is further enhanced through real-time analytics, enabling businesses to adapt quickly to market demands and minimize resources' wastage.

The ZL4460 stands out due to its combination of advanced technology and user-friendly integration capabilities. It is engineered to offer both high performance and ease of use, making it a favored option for many manufacturers. Additionally, its ability to adapt to existing systems without extensive modifications sets it apart from traditional components, marking a significant leap forward in the realm of industrial technology.

Yes, one of the advantages of the ZL4460 is its compatibility with both new and existing machinery systems. It is designed to be versatile enough to fit into a wide range of setups without extensive modifications. This not only simplifies the integration process but also saves costs associated with completely overhauling existing systems.

Regular inspections and calibration are recommended to ensure the ZL4460 operates at peak efficiency. However, because of its robust design, it requires minimal maintenance compared to standard components. Users are encouraged to utilize the real-time monitoring features to track system health and performance, which can highlight the need for maintenance before problems become critical.

Yes, manufacturers of the ZL4460 often provide comprehensive training sessions and resources to ensure users can maximize the system's potential. These training programs typically cover operational protocols, troubleshooting tips, and how to leverage data analytics for improved decision-making. Understanding the system fully can significantly enhance its benefits, allowing companies to optimize performance from day one.

Real-world experiences can often provide the best insight into the practical application and effectiveness of the ZL4460 system. Numerous organizations across different sectors have reported positive outcomes following its implementation. Here are a few notable case studies:

One manufacturing facility specializing in automotive parts modified its production line by integrating the ZL4460 system. Within the first month of deployment, managers noted a 25% increase in output. This uptick directly correlated with the ZL4460’s capacity to enhance process timing and reduce transition delays between steps in the assembly line. Furthermore, the predictive maintenance features led to a 30% decrease in equipment failure incidents, drastically reducing downtime and associated costs.

In the food processing industry, a leading company struggled with energy inefficiencies and wastefulness. By incorporating the ZL4460, they experienced a significant transformation in energy management, leading to a remarkable 15% reduction in overall energy consumption. The adaptability of the ZL4460 allowed it to seamlessly integrate with their existing machinery, minimizing the complexity of installation and subsequent training for the company's workforce.

Another case involved an aerospace manufacturer that employed the ZL4460 to enhance its quality assurance processes. Enhanced real-time data analytics permitted immediate quality checks, leading to a 40% increase in the accuracy of output measurements. This improvement not only streamlined the production cycle but also enhanced compliance with rigorous industry standards, ultimately bolstering the company's reputation for quality.

Looking ahead, the potential for the ZL4460 system appears limitless as technological advancements continue to reshape the landscape of industrial operations. As industries drive towards more sustainable practices, the ability of the ZL4460 to minimize energy consumption while optimizing performance positions it as a critical tool in the quest for greener manufacturing solutions.

The advancements in artificial intelligence and machine learning will only refine the capabilities of systems like the ZL4460. Future iterations may include even more sophisticated predictive algorithms that can anticipates issues before they manifest, ensuring smooth operations and further minimizing maintenance needs.

Moreover, as industries grapple with the challenges of supply chain disruptions and labor shortages, systems like the ZL4460 will increasingly play a role in automated systems that can function independently or with minimal human intervention. This shift will not only bolster productivity but also provide a safety net that allows companies to navigate uncertain market conditions more resiliently.

The incorporation of the ZL4460 system into industrial operations represents a significant step forward in manufacturing technology. By enhancing efficiency and reducing operational costs, it stands as a testament to the power of modern engineering. As industries continue to evolve, the ZL4460 will undoubtedly play a critical role in facilitating this progress, making it an essential component for those looking to stay at the forefront of industrial innovation.

With its robustness and adaptability, the ZL4460 is poised not just to meet the present and emerging industrial challenges but also to redefine the benchmarks of performance and reliability in the manufacturing sector. Embracing this technology will not only provide a competitive advantage but also prepare organizations for the future of smart manufacturing.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!