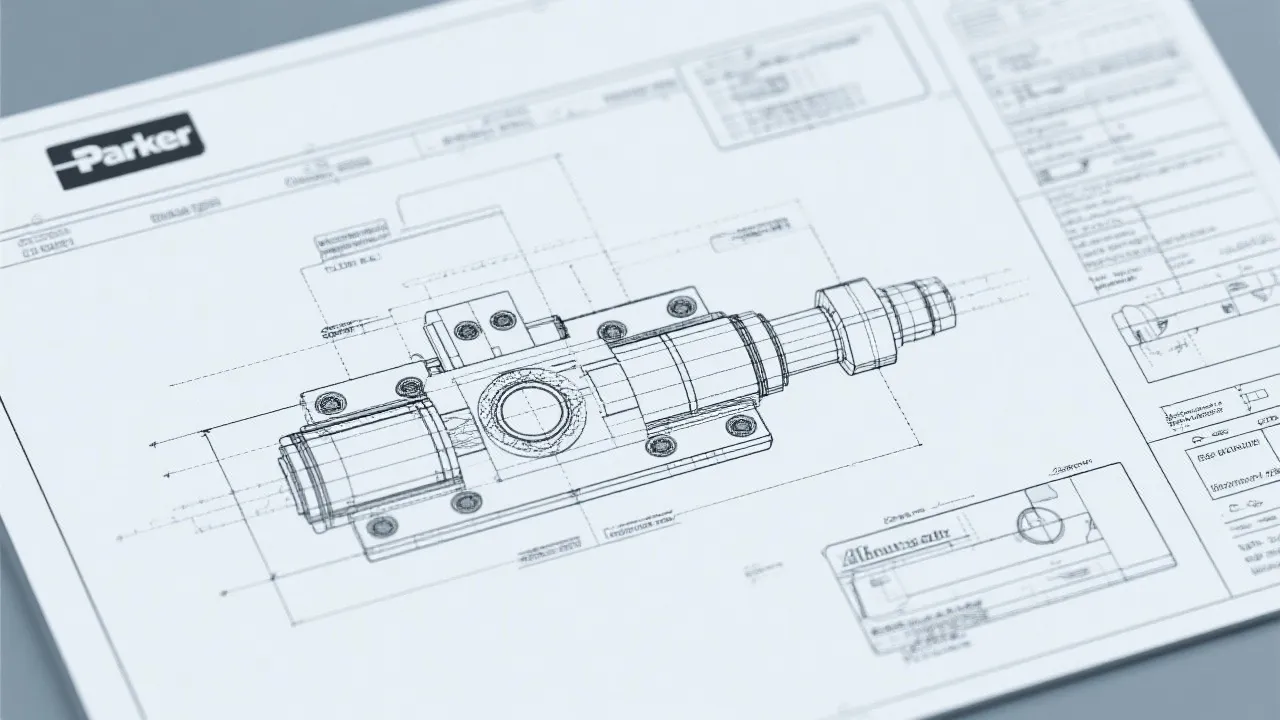

The Parker Actuator is a precision-engineered device integral in various industries for managing movement and force. This article delves into its features, benefits, and applications, offering insights into why it stands as a crucial component in industrial and automation settings.

The Parker Actuator is a high-precision device that plays a critical role in various industries, including automation, manufacturing, and aerospace. Known for its reliability and versatility, this actuator serves as a cornerstone in systems where controlled motion and force are paramount. In an ever-evolving industrial landscape, the ability to manage these elements with precision can define productivity, efficiency, and innovation.

Actuators like those from Parker function by converting energy into motion, typically through hydraulic, pneumatic, electric, or mechanical means. The Parker Actuator is particularly celebrated for its robust design, which ensures longevity and dependability in demanding environments. It is crafted to perform with exceptional precision, thereby minimizing errors and enhancing the overall output quality.

The integration of advanced materials and cutting-edge technology in Parker Actuators allows them to withstand high pressures and temperatures which are often encountered in industrial applications. For instance, in environments such as oil drilling or chemical processing, where conditions can be extreme, the actuator must maintain functionality to prevent system failures. This attribute makes them indispensable in fields requiring stringent operational standards.

Mechanically, Parker Actuators can utilize different operation modes based on their design—such as linear actuation for pushing or pulling, rotary actuation for turning tasks, or unique combinations thereof to fit specific applications. Each design not only addresses needs but also optimizes the energy required to perform the desired tasks, essentially enhancing machine efficacy further.

One of the standout features of the Parker Actuator is its adaptability. It can be tailored to meet specific requirements across diverse sectors, offering solutions that align with unique operational needs. This flexibility is paired with high performance, ensuring that processes are not only effective but also efficient.

Moreover, the Parker Actuator is designed with sustainability in mind. By optimizing energy consumption and reducing wear and tear on machinery, these actuators contribute to a reduction in operational costs and environmental impact, aligning well with contemporary calls for sustainable industrial practices. In a world increasingly focused on reducing carbon footprints, the introduction of efficient actuator technology can assist companies in meeting their sustainability goals while maintaining productivity and profitability.

| Feature | Advantage |

|---|---|

| High Precision | Ensures minimal errors and quality output. |

| Durability | Long-lasting performance in harsh conditions. |

| Energy Efficiency | Reduces operational costs and supports sustainability. |

The applications of Parker Actuators are extensive and varied, ranging from heavy machinery to sophisticated robotic systems. In the aerospace industry, for instance, these actuators are used to manage aerodynamic surfaces and landing gear. By leveraging their precise control capabilities, the actuation systems play a vital role in enhancing flight safety and performance.

Similarly, in manufacturing, they provide the precise control needed for assembly lines and automation systems. Here, the ability to cycle quickly while maintaining accuracy ensures that production volumes remain high without compromising on quality. For example, in automotive assembly, components can be positioned and tightened with precision, reducing the likelihood of defects and rework.

Additionally, in the energy sector, where efficiency and reliability are critical, Parker Actuators are utilized in applications such as pipeline operations, renewable energy systems (like wind turbines), and even in nuclear reactor control systems. Such widespread application underlines the versatility and indispensability of Parker Actuators in achieving high-performance standards across the board. By facilitating smooth and controlled motion, they ensure that machinery operates at optimal efficiency, which is vital in a landscape increasingly defined by competition and consumer demand for quality.

When considering the selection of the appropriate Parker Actuator for a specific application, various factors need to be taken into account. These may include load requirements, speed of actuation, environmental conditions, and the specific motion type required. Understanding these elements will contribute to the longevity and effectiveness of the actuator being utilized.

For instance, when selecting an actuator for a high-speed conveyor system, one would prioritize responsiveness and speed, alongside accuracy. In contrast, for applications requiring higher torque and force, one would select a model designed specifically to maintain efficiency under those conditions. Beyond operational characteristics, compatibility with existing systems must also be considered to avoid installation issues or inefficient workflow transitions.

Consulting with Parker’s technical resources or their network of distributors can provide value in the decision-making process. Their expertise can assist in forecasting potential issues and determining if specific enhancements or custom solutions are necessary based on the machinery's overall design.

In today's increasingly interconnected world, the integration of Parker Actuators with modern technology is becoming more prevalent. The advent of Industry 4.0 has introduced opportunities for smart automation, where devices communicate with one another and adapted IT systems for seamless operations. Parker Actuators can be integrated with IoT (Internet of Things) platforms, allowing for real-time monitoring and feedback on performance metrics, which can be invaluable for predictive maintenance.

For example, sensors can be installed to monitor the operational status of the actuator, collecting data on temperature, load, and performance. This data can then be analyzed to foresee failures before they occur, thus preventing unplanned downtime. Such integration not only enhances reliability but also supports overall system efficiency.

Furthermore, with the implementation of advanced control systems that utilize AI (Artificial Intelligence), Parker Actuators can be programmed to optimize their performance based on real-time conditions. By dynamically adjusting their operation parameters, they can adapt to variations in load or process requirements, accommodating fluctuations without human intervention.

The Parker Actuator exemplifies the fusion of engineering excellence with industry needs. Its reliability, efficiency, and adaptability make it a preferred choice among professionals seeking to enhance their systems’ performance and longevity. As industries evolve and demand more sophisticated solutions, the role of Parker Actuators in driving innovation and efficiency cannot be overstated, making them integral to futuristic industrial applications.

In conclusion, the continued development of Parker Actuators illustrates the manufacturer's commitment to leading the field of actuation technology. Industries are increasingly relying on such advanced devices to maintain competitiveness and ensure operational excellence. As technological advancements unfold, it is likely that we will witness even more innovative applications and capabilities emerging from products like the Parker Actuator, setting new benchmarks for performance, sustainability, and integration in various fields.

As we look into the future, several trends are expected to shape the landscape of actuation technology. The ongoing evolution of materials science is anticipated to bring forth materials that are lighter yet more robust, allowing for the construction of even more powerful and compact actuators. This will have significant implications in industries like aviation and automotive, where weight reduction is paramount for enhancing performance and fuel efficiency.

Moreover, the push towards automation and smart factories will likely lead to the further integration of artificial intelligence with actuators. This partnership has the potential to revolutionize manufacturing environments, enabling machines to learn and adapt in real-time. With the advent of sophisticated algorithms that can analyze data from actuators, we can expect a new era of autonomous production systems that continuously optimize their routines for maximum output and minimal waste.

The increase in sustainability-focused policies will also play a crucial role in shaping the design and implementation of future actuators. Manufacturers like Parker are already leveraging research into renewable energy sources to propose actuators that not only consume less energy but can also harness energy from their operational surroundings. Such developments could lead to self-sustaining systems where the need for external power sources is significantly reduced, aligning with global sustainability goals.

Furthermore, advancements in precision motion control technologies will enable actuators to operate at sub-micron levels, which is particularly beneficial in sectors such as semiconductor manufacturing and micro-assembly. The ability to manipulate parts at this level of precision opens up new opportunities for innovation, leading to products that were previously unimaginable.

Lastly, the interplay between the rise of electric vehicles and advancements in actuator technology highlights the importance of compact, efficient actuation solutions. As electric vehicles become mainstream, the demand for specialized actuators to control everything from braking systems to mobility functions will surge, paving the way for innovations that can meet these challenges.

In conclusion, the Parker Actuator stands as an exemplary model of engineering innovation, offering a blend of performance, adaptability, and sustainability that meets the demands of today’s industrial applications. As future trends in technology continue to unfold, these actuators will remain at the forefront, driving advancements that not only enhance efficiency and productivity but also contribute to a sustainable industrial ecosystem. The pathway laid by Parker in the actuator domain points towards a future where automation and precision will become seamlessly intertwined, reshaping industries across the globe.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!