Parker Actuators are pivotal components in industrial automation, providing precise control and movement in various industrial applications. These sophisticated devices are integral in sectors ranging from manufacturing to aerospace, ensuring enhanced performance and reliability. This article delves into the functionalities, types, and benefits of Parker Actuators, offering insights into their role in optimizing operations.

Parker Actuators are renowned for their precision and robustness in the industrial sector. These devices are integral to automating processes that require exact control and movement, thereby enhancing the efficiency and reliability of various systems. Industrial applications range from manufacturing setups to advanced aerospace machinery, all benefiting from the exactitude and resilience provided by these actuators. The technology has evolved significantly over the years, transitioning from simple mechanical systems to sophisticated digital solutions that can adapt to various operational demands.

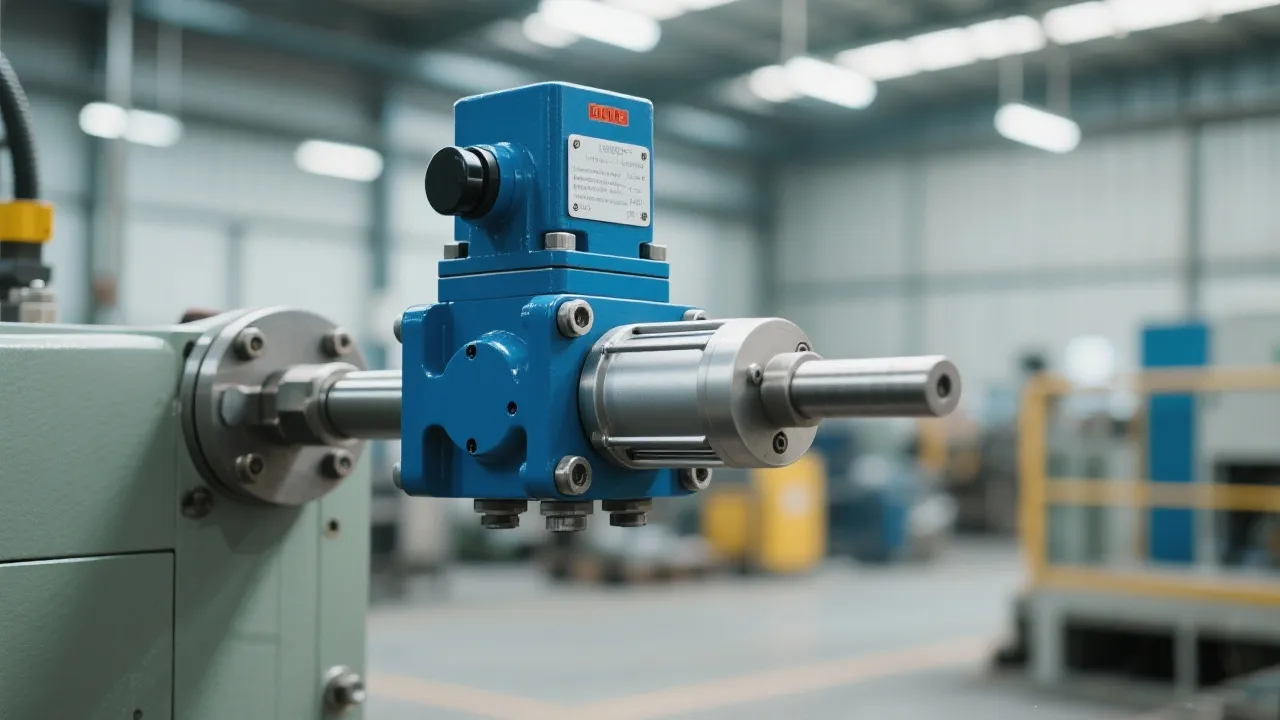

Parker offers a considerable variety of actuators, each designed to meet specific industrial needs. This extensive range includes hydraulic actuators, pneumatic actuators, and electric actuators, ensuring that all types of power sources and force requirements are addressed. Hydraulics are known for their power-dense nature, making them ideal for applications that require significant force over short distances; pneumatics are recognized for their easy installation and fast operation, suitable for applications that require quick movements; and electric actuators stand out for their precision and energy efficiency, perfect for intricate processes that necessitate fine control.

Additionally, Parker's range extends to specialized actuators such as linear and rotary models, each with its strengths tailored to specific tasks. Linear actuators convert rotational motion into straight-line motion, while rotary actuators are designed for turning applications, providing motion in a circular direction. This variety allows engineers to choose the most suitable actuator based on the unique requirements of their projects, ensuring optimized performance without unnecessary compromises. Whether it’s for heavy lifting in offshore oil platforms or precise positioning in robotic assemblies, Parker’s catalog caters to both common and highly specialized needs.

The decision to implement Parker Actuators is often driven by their robust design, high efficiency, and reliable operation across demanding environments. Parker is a brand synonymous with quality and performance, with its actuators designed to provide durable solutions tailored to meet complex industrial challenges. Their products are engineered to withstand stringent industry demands while enabling seamless integration into existing systems. This adaptability is crucial in industries where downtime can lead to significant financial losses.

Parker Actuators are built with advanced materials and technologies that enhance their durability. For instance, many hydraulic models utilize advanced seals and tubing that resist wear and tear, thereby extending the actuator's life cycle. In environments where dust, moisture, and chemicals are present, Parker's protective coatings and enclosures can prevent corrosion and damage, making them highly reliable even in the most challenging conditions. Furthermore, Parker’s commitment to continuous innovation ensures that their actuators incorporate the latest technological advancements, allowing users access to state-of-the-art solutions that keep pace with the rapid advancement of industrial technology.

Industries such as manufacturing, automotive, aerospace, and material handling benefit greatly from the precision and reliability of Parker Actuators. In manufacturing, these actuators facilitate automation in production lines, helping maintain consistent quality and increasing operational speed. They are used to control conveyors, robotic arms, and assembly systems, significantly enhancing overall productivity.

Aerospace utilizes their precision for control systems, ensuring high safety standards are maintained. Aircraft control surfaces, landing gear systems, and cargo door mechanisms often rely on Parker’s electric and hydraulic actuators. The reliability and lightweight design of these actuators prove vital in aerospace applications, where even the smallest efficiency improvements can have substantial impacts on performance and fuel management.

Material handling applications rely on this technology for efficient load manipulation, reducing downtime and improving system throughput. Automated guided vehicles (AGVs), palletizers, and sorting systems benefit from the speed and responsiveness of Parker actuators, facilitating smoother operations while minimizing labor costs. In fact, the integration of Parker Actuators into such systems often leads to a significant increase in operational flexibility, allowing for quick reconfiguration and adaptability to changing production demands.

Opting for Parker Actuators offers multiple advantages, including enhanced control, increased productivity, and reduced energy consumption. The actuation solutions provided by Parker ensure precise control over movements, thus lowering error rates and increasing output quality. By automating repetitive tasks, these actuators minimize the need for manual intervention, elevating productivity levels while reducing energy consumption associated with manual processes.

Another vital benefit is the actuator's compatibility with advanced control systems, including programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems. This integration allows for real-time monitoring and adjustments, ensuring optimal performance across various processes. By leveraging data gathered from sensors and control systems, businesses can further enhance their efficiency and respond quickly to potential issues before they escalate, ensuring smooth and efficient operations.

Parker also stands out due to its customer-centric approach, providing comprehensive support and expertise throughout the lifecycle of their actuators. From initial selection and installation through to maintenance and troubleshooting, customers can rely on Parker’s extensive resources and knowledgeable staff to maximize the benefits of their products. This level of service is invaluable in today’s fast-paced industrial landscape, where operational disruptions must be minimized, and efficiency maximized.

| Actuator Type | Advantages | Ideal Applications |

|---|---|---|

| Hydraulic Models | High force density, robust design, suitable for heavy loads | Heavy machinery, construction equipment, aerospace applications |

| Pneumatic Models | Rapid response, easy maintenance, cleaner operation | Assembly lines, material handling, food processing |

| Electric Models | Precision, energy-efficient, quiet operation | Automation systems, robotics, medical devices |

According to industry experts, the choice of actuator significantly impacts the efficiency and productivity of industrial operations. Investing in Parker Actuators is considered a strategic move for businesses aiming to optimize their performance and maintain a competitive edge in a rapidly evolving market. Experts advocate for careful assessment of application needs and environmental conditions when selecting actuator technology, ensuring alignment with organizational goals and operational requirements.

Furthermore, industry analysts note that the trend toward automation and smarter manufacturing processes has made the selection of appropriate actuator technology even more critical. As businesses transition to Industry 4.0 models, the integration of intelligent actuators capable of communicating with other system components is becoming essential. Parker Actuators not only offer physical motion control but are designed to integrate with various IoT platforms, thus ensuring that businesses can harness data analytics and improve overall performance.

Experts also emphasize the importance of considering long-term support and product longevity when selecting actuators. Parker's reputation for reliability and durability means that organizations can expect their systems to perform at a high level over extended periods with minimal maintenance, thus lowering operational costs. In an era where downtime is extremely costly, this assurance can significantly influence purchasing decisions.

Q1: What factors should be considered when selecting a Parker Actuator?

A: Key considerations include the application's force requirements, speed, precision, and environmental conditions. It’s crucial to evaluate the specific operational requirements and select the actuator type that aligns best with these needs. Industry experts recommend evaluating power source compatibility and maintenance ease as additional factors in the decision-making process.

Q2: How do Parker Actuators contribute to energy efficiency?

A: Parker Actuators are designed to optimize energy usage by reducing unnecessary mechanical processes and enhancing precision in operations, thereby minimizing energy waste. The integration of smart technology allows for adjustments based on load and speed requirements, further contributing to energy conservation.

Q3: Are Parker Actuators customizable for specific industrial needs?

A: Yes, Parker provides solutions tailored to specific requirements, allowing modifications to meet particular operational demands. Customization options include alterations in size, power ratings, and even the integration of specific control technologies, ensuring seamless integration within existing systems. This flexibility is particularly advantageous for industries with unique requirements or for those operating under specialized conditions where standard products may not suffice.

Q4: What is the expected lifecycle of Parker Actuators?

A: The expected lifecycle of Parker Actuators can vary based on their specific application, load, and maintenance practices, but they are designed for long service life in demanding environments. With proper installation and routine maintenance, many Parker actuators can function reliably for several years, often exceeding competitive offerings in the market.

Q5: Can Parker Actuators be used in harsh environments?

A: Yes, Parker Actuators are designed to operate in various harsh environments including extreme temperatures, moisture, dust, and corrosive settings. For applications in such conditions, Parker provides additional options like enhanced sealing technologies and specialized coatings that help protect the actuator and ensure continued operational integrity.

Parker Actuators exemplify industry-leading innovation in motion and control technologies. They provide reliable, efficient, and precise control solutions for diverse applications, offering significant benefits to enterprises aiming for excellence in their operational dynamics. By understanding the types and applications of Parker Actuators, businesses can leverage these tools to optimize systems and gain a distinct advantage in today's competitive market landscape.

In conclusion, the role of actuators in industrial automation cannot be overstated. As technology continues to advance, the demand for more efficient, adaptable, and precise actuator solutions will only grow. Parker's ongoing commitment to research and development ensures that they remain at the forefront of actuator technology, continually meeting the evolving demands of various industries. Organizations looking to enhance their operational capabilities must consider the potential of Parker Actuators as part of their comprehensive automation strategy, thereby positioning themselves for success in a rapidly changing industrial environment.

To further demonstrate the impact of Parker Actuators, consider case studies from multiple sectors where these solutions have been employed. In the automotive industry, automated assembly lines that utilize Parker pneumatic actuators have reported productivity increases of up to 30% thanks to improved speed and precision in handling components. Likewise, in the packaging sector, the integration of Parker electric actuators in robotic packaging systems led to lower energy consumption and reduced operational costs, allowing companies to pass savings onto consumers while maintaining high-quality output. Such evidence of effectiveness underscores the necessity of choosing Parker Actuators for future-proof operational excellence.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!