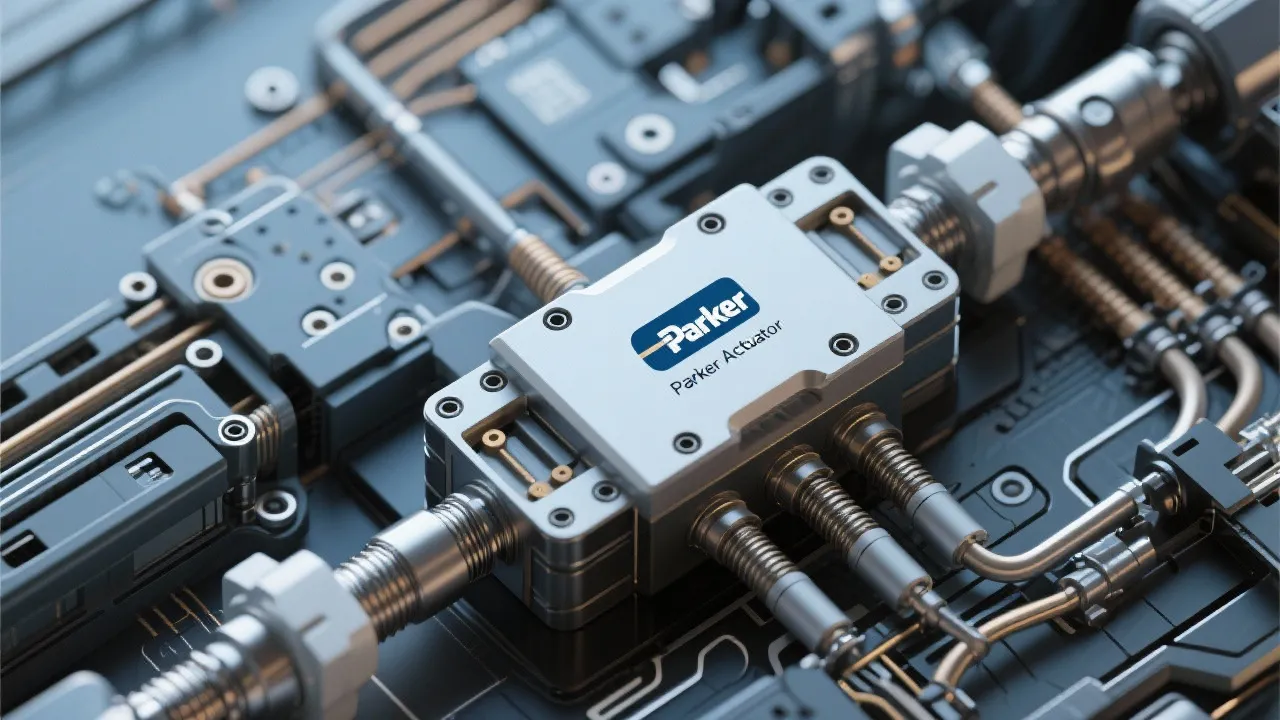

Parker actuators play a pivotal role in various industries, offering precise motion control solutions. Known for their robust design and reliability, these actuators are essential in sectors ranging from automotive to manufacturing. This article delves into their importance, applications, and technological advancements that position Parker as a leader in the actuator market.

Parker actuators are an integral component in the realm of industrial automation, providing precision control and movement across a myriad of applications. Known for their durability and efficiency, Parker actuators are employed in industries such as aerospace, automotive, manufacturing, and more, satisfying diverse engineering requirements with exceptional performance. With continued growth in automation technologies, Parker has positioned itself as an industry leader by continuously innovating and improving its range of actuators to meet the evolving demands of various sectors.

At the heart of many mechanical systems, actuators convert energy into motion. Parker actuators distinguish themselves through innovative design, ensuring they meet precise control specifications and perform reliably under demanding conditions. They cater to applications requiring linear or rotary motion, spanning everything from robotics to CNC machinery. The versatility of these actuators allows them to function in a multitude of settings, enhancing productivity and efficiency. Actuators play a pivotal role in converting electrical energy into mechanical motion, where the specific type of actuator chosen can greatly affect the performance and operation of the entire system it is part of.

Parker actuators offer several advantages, such as high load capacity, energy efficiency, and reduced maintenance needs. These features significantly enhance operation efficiency and cost-effectiveness, proving invaluable in large-scale manufacturing settings. With their ability to operate under extreme conditions, Parker actuators ensure a stable performance, significantly impacting the reliability of automated systems. Let's delve deeper into some of the key benefits that set Parker actuators apart from their competitors.

Parker actuators are engineered to handle substantial loads without compromising performance. This attribute makes them ideal for heavy-duty applications, notably in construction and automotive industries. For instance, in automotive assembly lines, Parker actuators lift and position heavy car parts with accuracy and reliability, ensuring that assembly processes are both safe and efficient. The design of these actuators often includes robust materials and advanced engineering that allow them to withstand shock loads and cyclic fatigue, which are critical in environments that demand high performance.

In today’s energy-conscious landscape, energy efficiency stands as a crucial factor. Parker actuators are designed to optimize power consumption, thus reducing operational costs and contributing to sustainable industrial practices. They utilize advanced control algorithms and design features to minimize energy waste during operation, which is especially important in settings where prolonged use can lead to high energy bills. In addition to directly reducing costs, the energy-efficient nature of Parker actuators reinforces a company’s commitment to environmental responsibility, as less energy consumption translates to lower carbon emissions.

The robust construction of Parker actuators leads to a longer lifespan, requiring minimal maintenance. This aspect allows companies to focus on productivity without the downtime associated with frequent repairs. Many Parker actuators are designed with fewer moving parts or use materials that resist wear, which directly results in less frequent maintenance intervals. Companies utilizing Parker actuators benefit from increased uptime and the financial advantages it brings, as less maintenance translates to lower labor costs and fewer disruptions in production schedules. In critical operations, the reliability of these actuators can be a decisive factor for businesses striving for continuous output.

Parker actuators prove their versatility through broad applications, from simple motion tasks to complex systems requiring accurate control. Below, we explore the diverse sectors where Parker actuators play an essential role:

Recent technological advancements have further cemented Parker’s position as a leader in actuator technology. Integration with digital control systems and smart technologies have enhanced the functionality and customization potential of these actuators, catering to modern industrial needs. As industries continue to evolve and the demand for automation increases, Parker has stayed at the forefront by embracing innovations that drive competitiveness and performance.

With the advent of Industry 4.0, Parker has innovated by integrating digital sensors and connectivity into their actuators, facilitating real-time monitoring and control while improving operational transparency and efficiency. Actuators equipped with IoT connectivity can relay feedback and performance data directly to operators or automated systems, creating opportunities for real-time adjustments. This digital feedback loop enables operators to optimize processes based on live data, thus improving overall productivity. Additionally, having access to real-time performance metrics allows for better forecasting and resource allocation within a manufacturing setting.

Incorporating smart technology has allowed Parker actuators to adapt dynamically to changing conditions, benefiting from self-diagnostic capabilities and predictive maintenance alerts to avert potential downtimes. Smart actuators can perform self-checks to ensure that all systems are working correctly, alerting operators to any issues before they result in failures. This predictive maintenance capability allows companies to schedule maintenance during planned downtimes instead of reacting to unexpected breakdowns, significantly enhancing the reliability of operations. The ability to customize actuator settings based on real-time data further enhances operational flexibility, allowing businesses to respond swiftly to changing demands or conditions.

| Feature | Benefits |

|---|---|

| High Load Capacity | Supports demanding applications with robust performance. |

| Energy Efficiency | Minimizes power usage, reducing operational costs. |

| Digital Integration | Enhances real-time control and monitoring capabilities. |

| Smart Technology | Offers adaptive control and predictive maintenance. |

Parker actuators hold a distinguished place in the world of industrial mechanics, recognized for their innovation, reliability, and efficiency. As industries evolve and the demand for intelligent, energy-efficient solutions grows, Parker is poised to continue its legacy of excellence, providing actuators that not only meet but exceed the needs of modern engineering landscapes. With ongoing developments and a commitment to research and innovation, Parker is well-equipped to tackle future challenges in industrial automation, ensuring that their actuators will continue to lead the way in performance and capability. This strong forward-thinking approach is crucial as industries across the globe strive for greater efficiency, productivity, and sustainability. By choosing Parker actuators, businesses are not just investing in a component but are securing a strategic advantage in their operational capabilities.

Looking ahead, the landscape of actuator technology is poised for transformation as industries increasingly adopt automation and smart technologies. Parker is committed to staying at the forefront of these advancements, leveraging its expertise to innovate solutions that address new challenges. The integration of artificial intelligence (AI) into actuator systems represents one of the most significant strides towards creating intelligent manufacturing cells capable of self-optimization and decision-making.

The integration of AI into actuator technology will enable systems to learn from historical data and adapt their performance dynamically. For example, actuators equipped with AI algorithms can predict when they might fail based on usage patterns and environmental factors, subsequently adjusting their operation to minimize wear and tear. This transition to smarter systems will revolutionize maintenance practices, allowing businesses to shift from reactive maintenance to a more proactive approach that prevents failures before they occur.

As IoT devices continue to proliferate, the interplay between Parker actuators and other connected devices will create opportunities for even greater automation efficiencies. Enhanced connectivity capabilities will allow for seamless integration with existing factory networks, facilitating a more cohesive operational ecosystem. The future will likely see Parker actuators providing not only motion but also data and insights that contribute to overall system performance. By leveraging cloud computing resources, businesses will be able to analyze vast amounts of actuator performance data, resulting in enhanced decision-making processes regarding production strategies, resource allocation, and predictive maintenance schedules.

Another area of potential growth for Parker actuators lies in the exploration and use of new materials. Advances in material science could lead to the development of actuators that are lighter, more durable, and more efficient. The introduction of advanced composites and lightweight metals can reduce the overall weight of hydraulic and pneumatic systems, enhancing their efficiency, while simultaneously increasing their strength and operational lifespan. Such advancements could pave the way for the next generation of actuators that meet the increasing demands of high-speed and high-precision applications.

The global trend towards automation, driven by the need for enhanced productivity, reduced labor costs, and improved product quality, indicates that the market for actuators will continue to grow. As manufacturers seek to incorporate Automation into every level of their operations, the demand for versatile, adaptable, and efficient actuators like those offered by Parker will surely increase. Integrating advanced features while maintaining affordability will be critical for Parker and other actuator manufacturers as they compete in this evolving market. The agility to adapt to market demands and technological trends will define the future success of actuator solutions.

In conclusion, Parker actuators not only represent the cutting edge of actuator technology but also hold the promise of future advancements that will further revolutionize industrial automation. As we traverse further into the era of smart manufacturing, Parker's commitment to innovation ensures that they will remain a key player in delivering solutions that help businesses overcome e challenges, increase productivity, and promote sustainable practices crucial for the future. Their focus on emerging technologies will provide clients with the tools they need to thrive in an increasingly complex and competitive global marketplace.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!