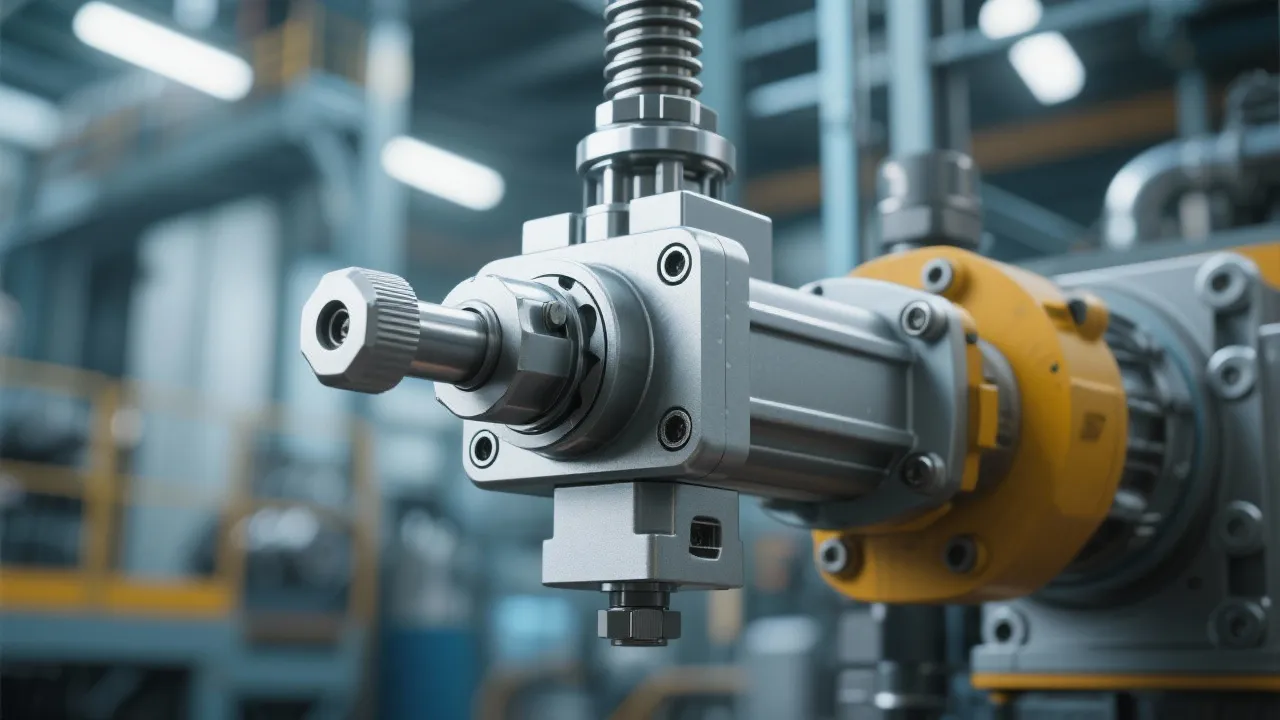

This guide elucidates the intricacies of Parker actuators, offering insights into their functionality and application across various industries. Actuators are crucial components in mechanical systems, converting energy into motion. Parker, a renowned industry player, offers robust solutions suited for diverse industrial requirements, reinforcing efficiency and reliability in mechanized operations.

In the realm of industrial machinery and automation, actuators play a pivotal role in transforming energy into motion, a critical function that shields the efficiency and productivity of mechanized operations. The significance of actuators extends far beyond mere movement; they serve as the crucial link between control systems and mechanical components, enabling precise adjustments and operations in various applications. Parker Actuator stands out as a player that provides robust, reliable solutions for this fundamental task, offering an extensive range of products that support a multitude of applications across different sectors.

Parker Actuator is an integral component widely used across different industries. Known for their ability to precisely and efficiently manage motion, Parker’s actuators are indispensable in sectors such as manufacturing, robotics, aerospace, and automotive industries. Their diverse range includes pneumatic, hydraulic, and electric actuators, each designed to meet specific motion requirements and operational challenges. With continuous advancements in technology and innovations in design, Parker has maintained a reputation for delivering high-quality products suited for modern industrial demands.

Parker provides various types of actuators, each with unique features suited to different industrial needs. Understanding the specific attributes of each type aids businesses in selecting the most suitable actuator for their operations:

The applications of Parker Actuators are wide-ranging, reflecting their versatility and effectiveness in diverse sectors. Below are some key areas where these actuators are employed:

When industries opt for Parker actuators, it’s usually due to several compelling reasons that outline the advantages of their products:

Parker actuators offer unparalleled precision and durability, tailored for advanced and heavy-duty applications. The combination of quality materials, cutting-edge design, and a strong focus on customer satisfaction sets Parker apart in the competitive landscape of actuator manufacturers.

Choosing the right actuator involves evaluating several factors such as operational needs, including the desired motion type (linear or rotary), energy consumption, required force, speed, and scalability. It’s prudent to engage with experts to analyze these criteria and select an actuator that aligns with both current and future requirements.

Regular maintenance is essential to ensure the longevity of Parker actuators. Routine inspections for wear and tear, keeping components lubricated, and ensuring secure connections will help in extending the product’s life and maintaining operational efficiency. Custom maintenance schedules based on usage frequency and environmental conditions are encouraged.

Yes, Parker actuators are designed with energy efficiency in mind. Utilizing advanced technologies and efficient control mechanisms, Parker actuators consume less energy while delivering high performance, making them ideal for environmentally conscious operations.

Parker actuators are designed for easy integration with various control systems, including programmable logic controllers (PLCs) and motion control systems. Their compatibility allows for seamless incorporation into existing automated systems, enhancing overall operational capabilities.

Parker actuators find applications in a variety of industries including manufacturing, aerospace, automotive, food and beverage, pharmaceuticals, and more. Their flexibility and reliability ensure that a broad spectrum of industrial sectors can benefit from their advanced motion control solutions.

As industry demands for automation and mechanization increase, the need for reliable actuators grows. Parker Actuators not only meet these needs but excel by providing a range of solutions that promote efficiency, precision, and reliability, making them indispensable in modern mechanical applications. Leveraging Parker’s advanced technology can offer a competitive edge by optimizing machinery performance and supporting innovation across various sectors. The focus on quality, engineering excellence, and customer-centric solutions positions Parker as a trusted leader in the actuator market, promising both current and future advancements in motion control technology.

As technology continues to evolve, the future of actuator technology looks promising. Innovations in materials science, automation, artificial intelligence, and connectivity herald a new era of actuators that are not only more effective but also smarter. Businesses can expect to see several trends shaping the future landscape of actuator technology:

The practical applications of Parker actuators across various industries highlight their versatility and efficiency. Below are case studies that illustrate how companies have effectively implemented Parker actuators in their operations:

Actuators are not merely components within mechanical systems; they are fundamental elements that dictate the performance and efficiency of industrial operations. As industries continue to evolve, the demand for advanced actuators is likely to surge. The contributions of Parker actuators demonstrate a commitment to reliability, innovation, and performance in the face of growing technological challenges. With a diverse array of actuators tailored for specific needs, Parker stands equipped to support industries striving for automation, efficiency, and excellence.

For those interested in delving deeper into the world of actuators, Parker provides a wealth of resources. Their website features comprehensive product catalogs, technical specifications, and case studies that are invaluable for understanding how to effectively implement their actuators. Additionally, they offer training sessions, webinars, and workshops that equip engineers and industry professionals with the knowledge necessary to optimize actuator applications in their respective fields. Staying updated with industry standards and emerging technologies is vital for professionals dedicated to leveraging the best actuator solutions available.

As we look forward to the future of actuators, it is clear that continuous innovation will play a critical role in shaping their development. By embracing new technologies, exploring enhanced materials, and integrating smart features, Parker and other actuator manufacturers are set to revolutionize motion control across various sectors. The integration of actuators into smarter systems reflects a broader trend towards automation that will redefine manufacturing processes and improve efficiency across industries. As businesses seek to remain competitive in an increasingly automated world, the role of actuators will undoubtedly become more prominent, emphasizing the need for quality and reliability in actuator selection and application.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!