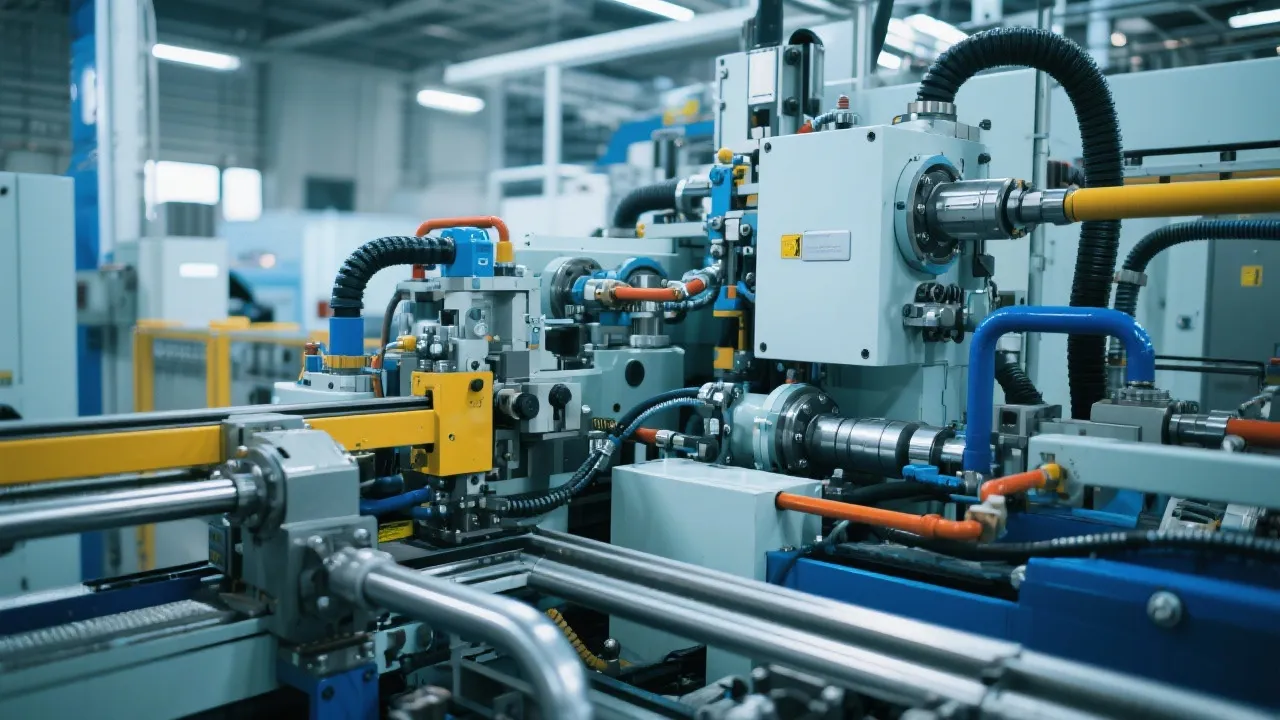

The Parker actuator plays a vital role in modern industrial automation and control systems. Renowned for its precision and reliability, Parker Hannifin’s actuators serve various sectors from aerospace to manufacturing. This article delves into their functionalities, benefits, and differentiates them from other actuator technologies, highlighting why they are a preferred choice for engineers and manufacturers globally.

In today’s fast-evolving industrial landscape, automation and precision are paramount. Among the pivotal components driving these advancements are actuators, with Parker actuators being synonymous with quality and innovation. Known for their reliability, these devices are integral in converting control signals into mechanical motion across various applications, including manufacturing, robotics, and aerospace. This article provides an expert analysis of their functionality, benefits, and industry applications, showcasing how they have become indispensable tools in various sectors.

Parker Hannifin, the renowned manufacturer behind these actuators, has built a reputation grounded in quality engineering and technological advancement. Parker actuators are known for their durability, consistency in performance, and precision. Their design takes into account various operational demands such as speed, load capacity, and environmental conditions, making them adaptable solutions for both standard and customized applications.

Parker actuators utilize advanced technologies and materials to ensure high levels of efficiency and effectiveness. This commitment to innovation has placed Parker at the forefront of the actuator market. Many of their designs incorporate feedback mechanisms that enhance responsiveness and control, contributing to optimized performance across all applications. Additionally, the integration of smart technology has allowed for predictive maintenance, reducing downtime and operational costs for companies that rely on these systems.

| Feature | Parker Actuators | Other Actuators |

|---|---|---|

| Material Quality | High-grade materials ensuring longevity, including advanced composites and alloys | Variable, often standard-grade that may compromise longevity |

| Precision and Control | Exceptional precision due to advanced control systems and feedback mechanisms | Moderate precision, heavily reliant on brand and model |

| Energy Efficiency | Optimized for energy savings and minimal heat loss | Varies; may focus less on energy efficiency leading to higher operational costs |

| Application Versatility | Highly adaptable to diverse applications without significant modifications | Generic adaptability may require customization, adding to costs |

Parker actuators are extensively utilized in industries such as:

What is the typical lifespan of a Parker actuator? Due to their high-quality construction, Parker actuators generally have a long lifespan, often exceeding expectations in demanding environments. Factors such as proper installation, the conditions of use, and regular maintenance can additionally enhance their longevity.

Can Parker actuators be used in extreme temperatures? Yes, they are designed to operate efficiently across a wide range of temperatures. However, specific models may be optimized for particular conditions, including extreme cold or heat, ensuring performance remains stable regardless of environmental challenges.

Are these actuators customizable? Parker offers customization options to meet specific industry requirements, allowing for tailored solutions that align with unique operational needs. Custom modifications can include different sizes, load capacities, and specialized control features to support various applications.

How do Parker actuators contribute to energy savings? Parker actuators define energy efficiency through their design, which minimizes energy waste and maximizes output. By utilizing servo motors and intelligent control systems, they adapt their performance based on demand, ensuring that energy is used effectively. This is increasingly important in compliance with corporate sustainability initiatives and regulations aimed at reducing carbon footprints.

Parker actuators are a benchmark in the industry for high-performance, durability, and precision. Whether in robust industrial settings or delicate aerospace applications, they consistently deliver results that meet the rigorous demands of modern automation and control systems. As industries continue to shift toward more sustainable and efficient operations, the Parker actuator remains a pivotal technology enabling this transformation. Their ability to adapt to technological advancements and integrate with new systems highlights their essential role in the future of engineering and manufacturing. As companies increasingly pursue innovative solutions to enhance productivity and sustainability, the relevance of Parker actuators only continues to grow.

In conclusion, the quality of Parker actuators is not merely a promotional statement but an ongoing commitment to engineering excellence that holds up under stringent testing and scrutiny. Users are encouraged to consider not only the immediate applicability of these actuators in their current scenarios but also the long-term benefits they provide in terms of customization, durability, and operational efficiency. As new technologies emerge, Parker actuators will undoubtedly evolve alongside them, meeting and exceeding the challenges of tomorrow's industrial landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!