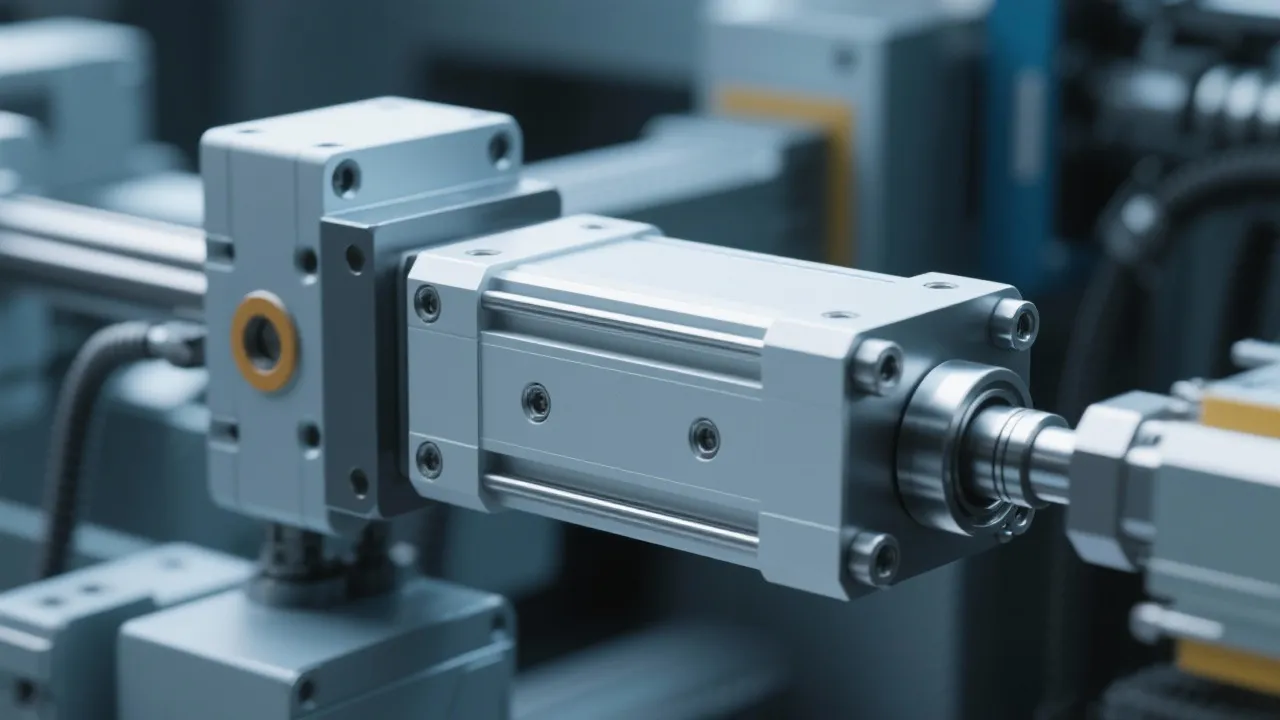

Parker actuators are critical components in industrial automation, providing precision and efficiency in various mechanical applications. These devices convert energy into motion, allowing for precise control in processes ranging from manufacturing to robotics. With cutting-edge technology and robust design, Parker actuators are vital for enhancing productivity and reliability in modern industry settings.

Parker actuators play a pivotal role in modern industrial processes by transforming energy into controlled motion. This essential function is the bedrock of automated systems, ensuring machines operate with precision and reliability. As you delve deeper into their utility, it becomes clear how indispensable these components are to sectors like manufacturing, robotics, automotive, and beyond. Their contribution to efficiency and productivity cannot be overstated, as they enable the seamless operation of various machinery and systems.

The journey of actuator technology mirrors the evolution of industry itself. Early actuators simply relied on mechanical force, like simple levers and pulleys, often operated manually. However, rapid technological advancements have transformed them into sophisticated devices capable of executing complex tasks with remarkable precision. Parker actuators, in particular, have been at the forefront of this evolution, continuously adapting to meet the ever-growing demands of modern industries. Over the years, advancements such as the integration of electronics in actuators have allowed for enhanced control, enabling features like positioning feedback systems which provide data on the actuator's performance in real-time.

Moreover, the shift from pneumatic and hydraulic actuators to electric solutions exemplifies the evolution of the technology, reflecting trends toward sustainability and energy efficiency. Electric actuators, like those offered by Parker, leverage electric motors for movement, which not only improves energy consumption but also enhances control over force and speed. This transition has also allowed for greater integration with computer systems, paving the way for smart manufacturing and IoT capabilities that are increasingly prevalent in today’s industrial settings.

Parker actuators come with a suite of advantages that make them a preferred choice for industry professionals. Firstly, their robust build ensures longevity and reliability, which can significantly reduce maintenance costs over time. The durability of Parker actuators is not merely a claim; it's a result of rigorous testing and quality control measures that they undergo during production. Secondly, the precision of these actuators allows for enhanced efficiency in production lines, directly impacting the bottom line of businesses. Whether it’s a high-speed packaging machine or a delicate assembly process, the accuracy with which Parker actuators operate can substantially improve product quality while minimizing waste.

Thirdly, the wide range of models means there is an actuator for virtually every need, whether it involves heavy-duty tasks or fine-tuned operations. Parker offers linear and rotary actuators, electric and pneumatic systems, customizable options, and various sizes, ensuring businesses can find the perfect fit for their specific applications. Furthermore, Parker Automation provides comprehensive support and resources to help users select the most appropriate actuator, making the decision-making process smoother and more informed.

Parker actuators are integral to a variety of applications across many industries. In manufacturing, they are used to automate assembly lines, ensuring consistent quality and maximizing throughput. For instance, automotive assembly lines benefit immensely from Parker actuators in robotic arms that assemble engine components or install parts with precision. This level of automation translates to faster production times and increased safety, as the risk of human error is minimized.

In robotics, these actuators drive movements and manipulations with precision, crucial for tasks that require high accuracy. Robots powered by Parker actuators are able to perform intricate tasks such as material handling, picking, and placing items in various configurations, all while maintaining consistent quality. The dexterity and flexibility offered by these actuators enable advancements in robotic applications ranging from medical surgeries to aerospace components assembly.

Moreover, in the automotive industry, they are utilized to control processes with agility and speed. Examples include their application in automated testing equipment for vehicles, where precise actuators control components to simulate real driving conditions, thereby ensuring vehicles meet safety and performance standards before they hit the market. Furthermore, in food and beverage production, Parker actuators help automate processes such as filling, capping, and packaging, contributing to improved hygiene and efficiency in compliance with regulatory standards.

| Specification | Details |

|---|---|

| Maximum Load | Varies depending on model but ranges from moderate to heavy-duty capabilities, making them suitable for a wide array of applications. |

| Stroke Length | Available in customized lengths to fit specific application requirements, ranging from very short strokes to several meters long, depending on operational needs. |

| Speed | Highly adaptable, catering to both rapid and slow-motion processes to accommodate the varying speeds required by different operations. |

| Material | Constructed from durable materials such as aluminum and stainless steel, designed to withstand harsh industrial environments and resist corrosion. |

| Control Systems | Many Parker actuators are equipped with advanced control systems, offering options for programmable logic controllers (PLCs) and integration with factory automation systems. |

| Environmental Resistance | Many models are rated for use in environments subject to dust, moisture, and temperature variations, making them ideal for outdoor or rugged settings. |

Parker actuators are renowned for their durability, precision, and versatility. Their advanced design ensures efficient performance across a range of applications, setting them apart from competitors. The company’s commitment to research and development continuously pushes the boundaries of actuator technology, allowing Parker to introduce innovative features such as energy-efficient motion control systems and real-time diagnostics compatible with smart manufacturing trends.

Yes, Parker actuators offer a level of customization that allows them to meet specific operational needs, making them suitable for a variety of custom applications. Clients can determine not just the size and type of actuator, but also features such as stroke length, control methods, and actuator speed based on their unique applications.

Actuators automate movement, which enhances precision and consistency, ultimately improving the overall efficiency and throughput of industrial processes. By minimizing the need for manual intervention, they allow for quicker production rates and less variability in operations, resulting in higher quality outputs. Furthermore, smart actuators equipped with sensors and connectivity options can monitor performance continually, allowing operators to make real-time adjustments that optimize efficiency.

Regular inspection and adherence to maintenance schedules can ensure the longevity and optimal performance of Parker actuators, reducing the likelihood of unexpected downtimes. Maintenance primarily involves checking for wear and tear, ensuring proper lubrication, and calibrating control systems. Parker also offers extensive support and resources for troubleshooting and maintenance, adding value to their products for end-users.

Yes, many Parker actuators are designed with IIoT capabilities, making them compatible with modern industrial automation systems. This integration allows for advanced monitoring and control functionalities, enabling users to track actuator performance, diagnose issues remotely, and implement predictive maintenance strategies. The ability to collect and analyze data from actuators contributes to smarter and more efficient manufacturing processes, aligning with Industry 4.0 objectives.

In conclusion, Parker actuators excellently represent the intersection of engineering prowess and industrial necessity. They are essential components that drive efficiency, reliability, and precision in numerous applications across various sectors. With their robust construction, tailored options, and state-of-the-art technology, Parker actuators deliver unmatched performance in today’s competitive industrial landscape. As industries continue to evolve and embrace cutting-edge technology, utilizing solutions such as Parker actuators will not only enhance operational capabilities but also ensure competitiveness and future-proofing against emerging challenges in the realm of automation and control.

The future of actuation technology appears bright, driven by advancements in artificial intelligence, machine learning, and Internet of Things (IoT) integration. Parker is well-positioned to lead this evolution, continuously innovating to meet the demands of a rapidly advancing industrial landscape. The integration of smart technologies with Parker actuators facilitates predictive maintenance and real-time operational adjustments, which are crucial for maximizing efficiency and reducing downtime in automated processes.

Furthermore, the move toward sustainability is influencing actuator design and manufacturing. Efficient energy consumption and materials that contribute to a reduced carbon footprint are becoming standard expectations in actuator technology. Parker's commitment to sustainability through their products not only adheres to regulations but also appeals to environmentally conscious consumers aiming to prioritize green practices within their operations.

Parker also recognizes the importance of education in utilizing their actuators effectively. The company offers numerous resources, including training sessions, user manuals, and technical support to ensure engineers and technicians can fully leverage the capabilities of Parker actuators in their applications. Knowledge of setup, optimization, and troubleshooting is vital, and Parker's commitment to customer education ensures that users get the most out of their investment.

With the pace of technical development in the actuator industry, staying informed about new products, industry standards, and best practices is essential. Parker’s workshops, webinars, and online platforms serve as vital tools for professionals seeking to enhance their understanding and application of advanced actuation technology. Such resources not only facilitate a learning culture within organizations but also contribute to a knowledgeable workforce that can adapt to evolving technological demands.

To understand the real-world impact of Parker actuators, consider these illustrative case studies that showcase their effectiveness across diverse applications.

A leading automotive manufacturer faced challenges in their assembly line operations, particularly in integrating robotic arms for body assembly. The previous actuators struggled with speed and precision, leading to bottlenecks and production delays. The company decided to implement Parker electric actuators tailored for high precision and speed.

Upon installation, the Parker actuators significantly enhanced the performance of the robotic arms. With the new actuators, the assembly line achieved a 30% increase in throughput while reducing the median cycle time per vehicle by approximately 20%. The accuracy of the actuators minimized scrap rates and ensured consistently high-quality assembly, resulting in overall cost savings and increased customer satisfaction.

In the food and beverage industry, a packaging plant was in search of solutions to improve its operational efficiency and ensure food safety compliance. The existing pneumatic actuators used for capping and sealing were inconsistent and prone to malfunction, leading to increased downtime and safety concerns.

By switching to Parker’s advanced electric actuators, the plant experienced a transformation. The electric actuators were not only more reliable but also provided smoother control over capping processes. The precision adjustments allowed for better seal integrity, significantly reducing spoilage and waste. Additionally, the energy efficiency of the new actuators decreased overall operational costs, demonstrating how modernization through Parker products can yield impressive returns.

A prominent aerospace manufacturer required reliable actuation solutions for component testing systems. The ability to simulate various flight conditions during the testing phase was critical, necessitating high-performance actuators capable of rapid responses and extensive range adjustments.

Parker actuators were evaluated for their compatibility with advanced flight simulation systems, focusing on their performance under strenuous conditions. The results were exemplary; Parker actuators enabled precise control of hydraulic systems mimicking real-world scenarios, ensuring that all tests could be completed within the stipulated time frame. The manufacturer was able to streamline its testing procedures and enhance the reliability of the components, which ultimately reinforced their market position as a leader in aerospace technology.

Parker actuators are more than mere components; they are strategic investments that can drastically enhance a firm’s operational capabilities across various domains. As evidenced by the aforementioned case studies, benefiting from innovative actuator technology can drive efficiency and reliability in production processes, irrespective of the industry. Coupled with a strong support structure and ongoing commitment from Parker to embrace progressive technology and sustainable practices, these actuators remain at the cutting-edge of industrial automation. Looking towards the future, it is clear that integrating advanced actuation solutions into operational frameworks will continue to be integral for businesses aiming to thrive in an increasingly competitive environment.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!