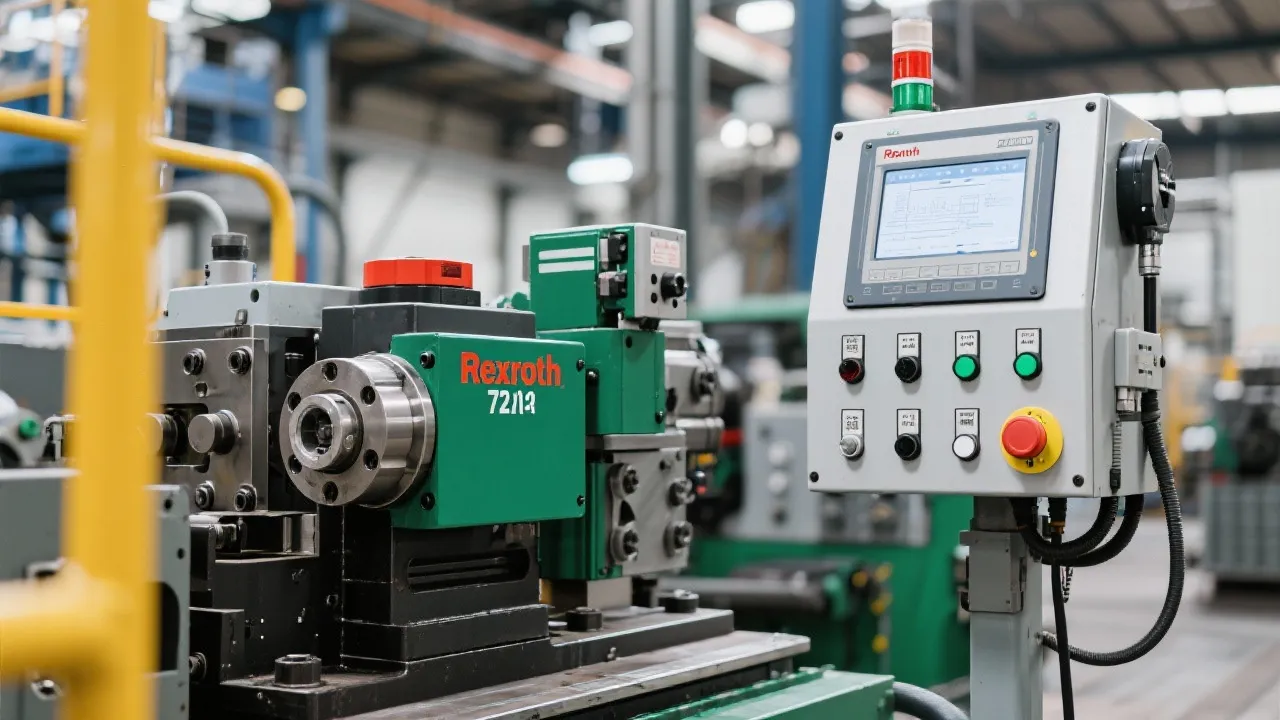

This article delves into the versatile applications of the Rexroth 7291, a component renowned for its efficiency in hydraulic systems. As a product of the notable Bosch Rexroth AG, it underscores a reputation for quality and innovation. Used primarily for its reliable function, the Rexroth 7291 is a staple in various industries requiring precise hydraulic operations. Discover its features, industry use cases, and more.

The Rexroth 7291 is a distinguished hydraulic component known for its exceptional performance and reliability in various industrial applications. From heavy machinery to precise engineering tools, the Rexroth 7291 plays a crucial role in ensuring operational efficiency and safety. As part of Bosch Rexroth AG's reputable product lineup, the 7291 continues to set standards in hydraulic systems through its innovative design and dependable functionality.

Hydraulics is a fundamental element of modern engineering and industrial operations. As systems rely increasingly on hydraulic technology, the demand for reliable components like the Rexroth 7291 has surged. Its engineering reflects a commitment to not only meeting but exceeding the expectations of engineers and operators alike. This commitment to excellence is backed by decades of research and development by Bosch Rexroth, a brand synonymous with quality in hydraulic machinery.

Bosch Rexroth AG has engineered the 7291 model to excel in robustness, longevity, and versatility, featuring numerous innovations that enhance its usability. Key features of the Rexroth 7291 include:

The Rexroth 7291 is integral to many systems across diverse sectors. Its applications include:

Choosing the Rexroth 7291 offers numerous benefits that can enhance operational efficiency across multiple applications:

When procuring the Rexroth 7291, working with a recognized supplier ensures authenticity and quality. This aspect is critical as the hydraulic components' integrity can significantly affect overall system performance. Partners in sectors nearby often provide added benefits such as tailored service packages and expert technical support, enhancing the value of the investment.

A reliable supplier can offer not only the correct specifications but also assist with installation, maintenance, and troubleshooting. This partnership can be instrumental in optimizing the performance of the Rexroth 7291 in its working environment. Many suppliers also maintain inventories of spare parts and accessories, which can reduce lead times for repairs and maintenance, allowing equipment to remain operational.

Furthermore, suppliers often organize training sessions or workshops, allowing workforce members to gain deeper insights into the hydraulic systems they operate. Such initiatives can significantly enhance the effectiveness of the workforce and ensure that they are well-prepared to handle routine operations and any unforeseen challenges.

| Attribute | Rexroth 7291 | Competitor A | Competitor B |

|---|---|---|---|

| Durability | High | Medium | Medium |

| Efficiency | High | High | Low |

| Cost | Competitive | Higher | Lower |

| Global Support | Excellent | Good | Poor |

| Customization Options | High | Medium | Low |

This comparative analysis illustrates the strengths of the Rexroth 7291 against its competitors. While both Competitor A and B offer some robust functions, the 7291 outshines its rivals in durability and global support. Moreover, the ease of customization makes it an appealing choice for businesses requiring adaptable hydraulic systems.

The Rexroth 7291 stands out as a formidable component in hydraulic systems across industries. It not only exemplifies Bosch Rexroth's dedication to quality and innovation, allowing users to harness its performance advantages effectively, but it also provides practical and flexible solutions in demanding environments.

As organizations look to optimize their operations for efficiency and cost-effectiveness, the role of high-quality components such as the Rexroth 7291 becomes increasingly important. For businesses striving for excellence and performance optimization, the Rexroth 7291 is an invaluable asset that promises to deliver outstanding results for years to come. In a market filled with options, the Rexroth 7291 establishes itself as a trusted choice, highlighted by its reliability, adaptability, and support.

Q: What industries typically use the Rexroth 7291?

A: Industries such as construction, agriculture, and automation frequently use the Rexroth 7291 due to its reliability and efficiency. Additionally, sectors involved in material handling, mining, and energy generation also see substantial benefits from using the Rexroth 7291 in their hydraulic systems.

Q: Why is Bosch Rexroth AG a preferred brand for hydraulic components?

A: Bosch Rexroth AG is renowned for its innovative engineering, durable products, and excellent customer support, making it a leader in hydraulic solutions. The company invests heavily in research and development, ensuring that its products continuously evolve to meet the needs of modern industries. Clients appreciate the comprehensive service and commitment to quality that Bosch Rexroth offers.

Q: How does the Rexroth 7291 compare in cost to competitors?

A: The Rexroth 7291 is competitively priced, offering excellent value given its durability and performance capabilities. While some competitors may offer lower initial pricing, the Rexroth 7291 often proves to be more cost-effective in the long run due to lower maintenance costs and higher reliability.

Q: Can the Rexroth 7291 be used in customized systems?

A: Yes, the Rexroth 7291's adaptability allows it to seamlessly integrate into customized hydraulic systems. Its design accommodates a variety of configurations, making it ideal for specialized applications. Clients can work with Bosch Rexroth or authorized retailers to modify the component to suit specific operational requirements.

Q: What maintenance is required for the Rexroth 7291?

A: Regular maintenance for the Rexroth 7291 includes routine inspections, checking for leaks, and ensuring proper fluid levels. Like any hydraulic component, it is essential to adhere to manufacturer guidelines on maintenance intervals. Users are encouraged to consult with certified Bosch Rexroth technicians for comprehensive service recommendations to ensure longevity and performance.

Q: What is the expected lifespan of a Rexroth 7291?

A: The expected lifespan of the Rexroth 7291 can vary depending on operating conditions, but many users report performance stability and reliability over a period of many years with regular maintenance. Proper installation and adherence to operational guidelines play significant roles in achieving maximal product lifespan.

In addition to the Rexroth 7291, companies should contemplate various factors when selecting hydraulic components for their systems. Factors such as compatibility, scalability, and performance specifications should be evaluated to ensure the chosen equipment will meet both immediate project demands and future operational goals.

Companies should perform thorough market research to compare various brands and products, much like how we detailed the comparative analysis in this article. Gathering feedback from industry peers can provide insights into real-world performances and challenges associated with different hydraulic solutions and components. Consultation with engineering experts is also advisable to ensure that the correct specifications are chosen to suit specific applications, thus preventing costly missteps.

The hydraulic industry is continually evolving, integrating the latest technology to improve component performance and system efficiency. Advanced sensors, IoT integration, and automated diagnostics lead the way in transforming traditional hydraulic systems into smart systems that can communicate real-time data, predict maintenance needs, and optimize performance.

Investing in modern hydraulic solutions not only enhances the efficiency and reliability of critical machinery but also allows organizations to remain competitive in a rapidly changing market. Adopting advancements such as electronic hydraulic drives or predictive maintenance tools can lead companies to significant long-term advantages in production rates and operational costs.

In conclusion, equipment like the Rexroth 7291 serves as a vital link in this ongoing evolution, providing robust functionality that meets the demands of both contemporary and future hydraulic applications. By staying abreast of technological trends and integrating high-quality components, organizations can fortify their operational frameworks and sustain a competitive advantage.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!