Polysulfide adhesives are renowned for their exceptional elasticity and chemical resistance, catering to industries requiring robust bonding solutions. These adhesives find extensive applications in construction, aerospace, and automotive sectors due to their superior performance in harsh environments, ensuring durability and flexibility over time.

Polysulfide adhesives are specialized bonding agents known for their remarkable properties such as elasticity, chemical resistance, and durability. These adhesives play a crucial role across various industries, particularly in construction, aerospace, and automotive sectors. Their unique composition allows them to maintain integrity and performance even under harsh environmental conditions. Polysulfide adhesives are formed through a polymerization reaction involving polysulfide resins, often complemented by a curing agent that enhances their overall effectiveness. This polymerization process significantly contributes to their extraordinary resilience and structural bonding capabilities, setting them apart in the adhesive marketplace.

The primary advantage of polysulfide adhesives lies in their outstanding elasticity, which provides the necessary flexibility for materials that experience movement or vibrations. This quality is particularly essential in dynamic environments where structural components might expand or contract due to thermal cycles or mechanical stress. Additionally, these adhesives boast excellent resistance to chemicals, oils, and fuels, making them ideal for demanding applications where chemical exposure is prevalent, such as in chemical processing facilities or transportation sectors. Their weathering resistance ensures that they remain effective over time, regardless of environmental factors, which is critical for outdoor applications.

Moreover, the adhesion performance of polysulfide adhesives is noteworthy. They bond effectively to a wide array of substrates, including metals, glass, plastics, and composites. This versatility allows them to be utilized in multifaceted applications, further enhancing their attractiveness to manufacturers and engineers. The long-term reliability and durability of these adhesives are also pivotal; they deliver consistent performance over time and can maintain adhesive strength even when subjected to challenging conditions such as high humidity and extreme temperature fluctuations.

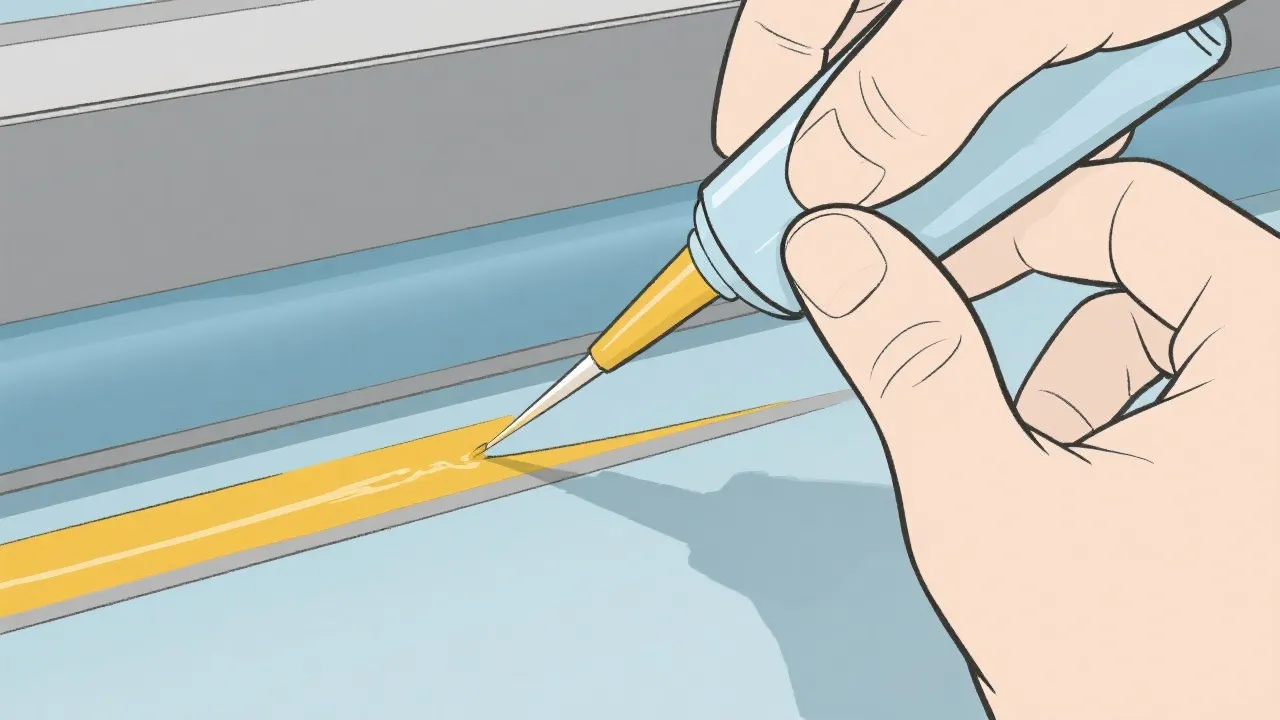

In the construction industry, polysulfide adhesives are frequently used for sealing and bonding tasks, particularly in areas prone to movement or requiring weatherproofing. They are commonly applied in the sealing of expansion joints, glazing, and roofs, providing a watertight seal that accommodates structural movements. The flexibility of these adhesives ensures that as buildings settle or shift due to thermal expansions or environmental factors, the integrity of the seal remains uncompromised.

Furthermore, polysulfide adhesives are valuable in applications such as bonding precast concrete elements, where they provide resilience against significant size variations and structural loading. They are also used in bridge construction to seal joints between different structural elements. This task is critical as it helps to prevent the ingress of water and contaminants that could lead to reinforcing member corrosion.

The aerospace sector benefits from the unique properties of polysulfide adhesives, especially in fuel tank sealing and structures subjected to high aerodynamic stresses. The ability to withstand exposure to aviation fuels and extreme temperatures without degrading makes these adhesives indispensable in aircraft manufacturing and maintenance. Their resistance to fuel and hydraulic fluids is essential for ensuring the safety and functionality of aircraft systems.

Additionally, polysulfide adhesives are utilized in the manufacturing of aircraft interiors, where lightweight and durable bonding solutions are essential. For instance, they are used to securely bond interior panels, ensuring that they remain intact even during pressurization and depressurization cycles encountered during flights. These adhesives contribute not only to structural integrity but also to the overall weight management of the aircraft, supporting fuel efficiency goals.

Automotive manufacturers utilize polysulfide adhesives for sealing engine components, windshields, and body panels. The adhesives' durability under fluctuating temperatures and resistance to automotive fluids ensure reliable performance, crucial for vehicle integrity and safety. Polysulfide adhesives' ability to bond dissimilar materials, such as glass to metal or plastic to metal, enables manufacturers to create vehicles that are more resistant to leaks and squeaks while enhancing aerodynamic efficiency.

Moreover, these adhesives are pivotal in modern automotive design, where reducing weight while maintaining strength is a significant engineering challenge. Their applications extend to bonding components in electric and hybrid vehicles, where managing thermal properties and battery encapsulation requires specialized adhesive solutions. The dynamic automotive landscape, characterized by rapid technological advancements and stricter regulations, continues to drive demand for high-performance polysulfide adhesives.

| Property | Description |

|---|---|

| Elasticity | High elasticity accommodates movement without cracking, ideal for dynamic structures. |

| Chemical Resistance | Withstands exposure to oils, fuels, and various chemicals, crucial for industrial applications. |

| Temperature Range | Performs well in a wide range of temperatures, from extreme cold to heat, ensuring versatility. |

| Adhesion | Excellent adhesion to a variety of substrates including metals, glass, and plastics, facilitating broad use. |

| Curing Time | Varies depending on formulation and environmental conditions; generally provides a workable time that balances between application and service. |

| Weather Resistance | Resists degradation from UV light, water, and extreme temperatures, enhancing longevity in outdoor applications. |

| Flexibility | Maintains flexibility post-curing, essential for applications subject to movement or stress. |

Choosing the right polysulfide adhesive involves evaluating several factors such as the specific application requirements, environmental conditions, and substrate materials. It is essential to consider the adhesive’s curing time, joint movement capability, and potential exposure to chemicals or extreme temperatures. Additionally, one must also assess the physical and chemical properties of the substrates involved, ensuring compatibility for optimal adhesion.

Moreover, understanding the manufacturing processes can also guide the selection. For instance, in cases where the adhesive will be subjected to extreme mechanical stresses or flexing, it is vital to select a formulation specifically designed for high dynamic load applications. It is also important to consult technical data sheets from manufacturers, which provide detailed specifications and recommendations tailored for specific industries or applications.

Polysulfide adhesives are used for applications requiring flexibility, chemical resistance, and weatherproofing, such as sealing expansion joints in construction, sealing fuel tanks in aerospace, and bonding components in automotive manufacturing. Their adaptability makes them suitable for a variety of environments, from outdoor applications exposed to weather elements to high-performance settings like aircraft and automobiles.

Polysulfide adhesives offer superior elasticity and chemical resistance compared to other adhesives, such as epoxies and polyurethanes, making them ideal for demanding environments where structural integrity and resistance to harsh substances are necessary. While other adhesives may excel in specific areas, polysulfide adhesives combine multiple beneficial properties, making them a versatile choice for numerous industrial applications. Additionally, their performance under varying humidity and temperature conditions is often more reliable than other adhesive types.

When used according to manufacturer guidelines and safety data sheets, polysulfide adhesives are safe. Proper personal protective equipment should be used to prevent skin contact and inhalation during application. It is crucial to follow all safety instructions, including adequate ventilation during use, as some polysulfide formulations may release fumes that could be harmful. Training for personnel using these adhesives is advisable to ensure safe practices and compliance with health and safety regulations.

As industries increasingly prioritize sustainability, polysulfide adhesives are evolving to meet environmental standards without compromising performance. Manufacturers are focusing on reducing the environmental impact of these adhesives through several innovative approaches. Development of more eco-friendly formulations, including low-VOC (volatile organic compounds) options, is one such initiative. These formulations not only comply with stringent environmental regulations but also contribute to greater indoor air quality when used in building applications.

Moreover, the durability and longevity of polysulfide adhesives can minimize the need for frequent repairs or replacements, thus reducing waste over time. Their capacity to withstand harsh environmental conditions and maintain structural integrity contributes to the overall longevity of bonded structures, which aligns with the sustainability goals prevalent in construction and manufacturing sectors.

In addition to formulation improvements, the recycling and proper disposal of materials containing polysulfide adhesives are also receiving attention. Industries are encouraged to develop comprehensive waste management strategies that include recycling efforts, which can help mitigate the environmental footprint of adhesive use.

The field of adhesive technology is rapidly advancing, with ongoing research leading to the development of high-performance polysulfide adhesives that cater to emerging market needs. Innovations in formulation, including the integration of nanotechnology and smart materials, are projected to enhance the performance characteristics of these adhesives significantly.

For instance, the addition of nanoparticles may improve the thermal and mechanical properties of polysulfide adhesives, making them even more effective under extreme conditions. Additionally, the development of self-healing polysulfide adhesives is on the horizon, which would allow for autonomous repair of bonded joints when damage occurs, thereby extending the lifespan of products and structures.

Furthermore, the growing trend towards lightweight and energy-efficient vehicles is likely to drive innovations in adhesive solutions that not only bond but also optimize the performance and weight of vehicles. Polysulfide adhesives may play a critical role in the future of automotive design, where reducing weight while maintaining safety standards remains a top priority.

Ending with the assurance of durable and lasting solutions facilitated by polysulfide adhesives, this comprehensive guide emphasizes their indispensable role in meeting complex industrial challenges, offering unparalleled bonding strength and reliability. Whether in construction, aerospace, automotive, or other sectors, polysulfide adhesives are shaping the future of materials bonding through constant innovation and adaptation to meet the evolving needs of industries.

As businesses continue to seek out sustainable and high-performance solutions, the future of polysulfide adhesives seems promising, ensuring they remain a vital component in the world of modern manufacturing and construction practices. By understanding their properties, applications, and selection criteria, industry professionals can harness the full potential of polysulfide adhesives to meet their project demands efficiently and effectively.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!