This article delves into the essential features and functions of the SW16G bearing, highlighting its pivotal role in mechanical applications. Bearings, as critical components, are designed to reduce friction between moving parts, enhancing performance and longevity of machinery. The SW16G bearing, in particular, is known for its durability and efficiency, making it a preferred choice in various industries worldwide.

The SW16G bearing is an integral component in the realm of mechanical engineering, renowned for its efficiency in minimizing friction between moving parts. Bearings like the SW16G are pivotal in ensuring the smooth operation and longevity of various machinery by reducing wear and tear on machine parts, ultimately enhancing overall performance. This bearing type can be found in everything from small household appliances to heavy industrial machinery, exemplifying its versatility and vital role in mechanical systems.

To better appreciate the significance of the SW16G bearing, it is essential to understand the role bearings play in machinery. When two components move relative to one another, friction can lead to wear, overheating, and eventual failure. The primary function of a bearing, therefore, is to provide a smooth surface upon which these components can rotate or slide, thereby reducing friction, enhancing operational efficiency, and ultimately prolonging the lifespan of the equipment.

One of the very notable features of the SW16G bearing is its robust design, which provides excellent load distribution and reduces vibration. This bearing is engineered to withstand high-speed operations with minimal maintenance, making it ideal for demanding industrial applications. The engineering behind the SW16G involves precision manufacturing processes that ensure a consistent, reliable performance characterized by less vibration and noise during operation.

Moreover, the SW16G is designed with materials that offer exceptional resistance to wear and corrosion. Typically made from high-quality steel alloys, these bearings also come with numerous protective coatings that enhance their durability against both mechanical stress and environmental challenges, such as moisture and dirt. Some variations may even include seals or shields that further protect the bearing's internal components, ensuring reliability and efficiency in operation.

SW16G bearings are prevalent in multiple sectors, including automotive, aerospace, and manufacturing, showcasing their adaptability and critical role in various machinery. In the automotive industry, these bearings are critical for components such as transmissions and wheel hubs. Their ability to tolerate high speeds while managing significant loads makes them indispensable in vehicles, where reliability and performance are paramount. Components within automotive systems are subject to harsh conditions, including temperature fluctuations and constant vibrations; the SW16G bearing is engineered to thrive in these settings.

In aerospace, the reliability of the SW16G bearing under extreme conditions ensures safety and efficiency. These bearings are often found in aircraft engines, landing gear mechanisms, and in-flight control systems, where precision and dependability are non-negotiable. Aerospace applications often require bearings that not only perform well significantly but also meet strict safety standards, which the SW16G exceeds due to its structural integrity and precision engineering.

Manufacturing processes also benefit greatly from the use of SW16G bearings. In automated machinery, such as conveyor systems and robotic arms, these bearings facilitate smooth and reliable operation, allowing for consistent production rates. The low maintenance requirements of the SW16G allow manufacturers to minimize downtime and enhance productivity, which translates to significant cost savings and operational efficiencies. Furthermore, the versatility of SW16G bearings means that they can be adapted to various manufacturing processes, including CNC machining, injection molding, and packaging, making them a vital asset across the production landscape.

When selecting a bearing, understanding its technical specifications is crucial. The SW16G bearing typically features a high-quality steel construction, providing resilience against environmental factors and operational stress. Its dimensions and load ratings are tailored to meet specific industrial needs, ensuring compatibility with numerous machine types.

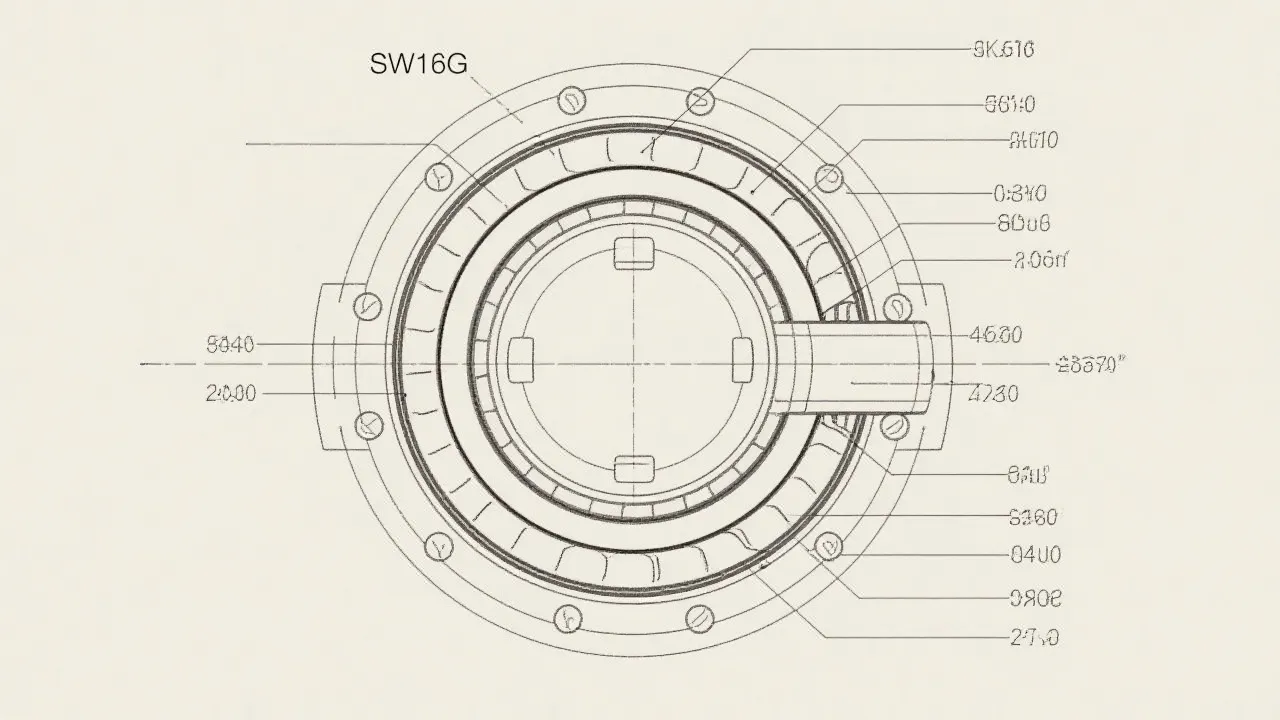

The technical characteristics of the SW16G include parameters such as its inner diameter, outer diameter, width, and load carrying capacity. These attributes determine how well the bearing will perform in its intended application. For example, the inner and outer diameters must be compatible with the shaft and housing respectively, while the width can affect the bearing's load capacity and stability. The load rating, specifically, indicates how much load the bearing can support without failing, which is critical in applications where heavy loads are common.

In addition to static load capabilities, considerations around dynamic load ratings – which account for moving loads – are also important in ensuring the chosen bearing will perform well under operational conditions. Engineers often conduct detailed calculations or refer to manufacturer specifications to ensure the selected bearing aligns with the application's operational parameters. Advanced software tools can assist in detailing these evaluations by simulating various operational conditions to predict how a bearing like the SW16G will behave. Furthermore, manufacturers may offer resources that provide guidance on selecting the best SW16G option based on specific use cases or requirements.

Comparing the SW16G to other bearing types highlights its superior performance. For instance, compared to standard ball bearings, the SW16G offers improved load handling and longevity. The chart below provides a comparative overview:

| Bearing Type | Load Capacity | Longevity | Maintenance Frequency |

|---|---|---|---|

| SW16G Bearing | High | Long | Low |

| Standard Ball Bearing | Moderate | Moderate | Moderate |

| Roller Bearing | Very High | Moderate | Moderate |

| Tapered Roller Bearing | High | Long | High |

This table provides a clear indication of how the SW16G excels in terms of load capacity and low maintenance frequency. While standard ball bearings are adequate for various applications, their limitations in handling high loads and susceptibility to wear make them less ideal for rigorous environments. Roller bearings, while offering high load capacities, may require more maintenance and be less suited for applications demanding a high degree of rotational precision. Conversely, tapered roller bearings can withstand heavy axial loads but often necessitate more frequent upkeep due to their complex construction.

Proper installation is key to maximizing the life and performance of the SW16G bearing. After ensuring the correct fit into the machinery part, it is essential to lubricate the bearing appropriately to prevent premature failure. Regular inspection for wear and re-lubrication at defined intervals can significantly prolong its service life. The proper lubrication not only reduces friction but also prevents corrosion and overheating, which are common issues in bearings that are not maintained adequately.

Installation involves several detailed steps. First, it is crucial to ensure that the housing and shaft dimensions are compatible with the SW16G bearing specifications. A clean work environment is essential; contaminants such as dust or debris can have detrimental effects on the bearing once installed. Before placing the bearing, visually inspect it for any indications of flaws which can include pitting, corrosion, or surface abnormalities that might affect its performance.

Once the bearing is installed, it’s vital to apply the correct type and amount of lubrication. Over-greasing can lead to increased pressure and heat, while under-greasing can result in insufficient protection against wear. Many manufacturers provide specific guidelines regarding the type of lubrication products suitable for their bearings, which typically include options like lithium grease or synthetic oils. Following these guidelines will enhance the operating life of the bearing.

Additionally, regular maintenance checks should include monitoring temperatures, noise levels, and overall performance. Instruments can provide valuable data over time, helping identify trends that may indicate potential failures or the need for maintenance adjustments. Conditions that lead to spindle misalignment or surface wear can be corrected before they necessitate more significant repairs or even replacements, optimizing the overall machine performance.

The advancement of technology has enormously influenced the design and manufacturing processes of bearings like the SW16G. Innovations in materials science have led to the development of advanced composites and alloys that can withstand greater stress and resist wear. New manufacturing methods such as precise machining and coating techniques have resulted in bearings that not only offer better performance but also contribute to reduced mechanical losses.

Furthermore, digitalization has introduced new possibilities in predictive maintenance through technologies like IoT (Internet of Things) and machine learning. Sensors can now be integrated into bearing assemblies to monitor operational conditions live, providing valuable insight into bearing performance. This data helps in proactive maintenance efforts by identifying potential issues before they lead to failure. For example, analyzing vibration frequencies can indicate misalignment or imbalance in rotating systems, allowing for timely corrections to be made. These technological advancements not only enhance the reliability of bearings but also contribute to substantial cost savings over the long term.

The future of bearing technology, including that embodied by models like the SW16G, looks promising with the integration of smart technologies and enhanced materials. Research is currently focusing on optimizing bearing design to enhance performance further while reducing material consumption and waste. This aligns with the broader trend towards sustainable manufacturing practices, where reduction in resource consumption and waste generation is pivotal.

Additionally, the growing trend of electrification in various sectors, especially the automotive industry, calls for bearings that can operate efficiently in unique environments. As electric vehicles become more prevalent, the demands on bearings will evolve, requiring them to possess characteristics suited to different operating conditions such as increased temperature or specific speed ranges.

Alongside this, the incorporation of nanotechnology is emerging as a promising frontier in bearing development. Coatings that reduce friction, improve corrosion resistance, and enhance resilience are being explored. These advancements may significantly enhance the performance of bearings like the SW16G in extreme applications.

Understanding the properties and applications of the SW16G bearing provides valuable insights for industries reliant on machinery efficiency and reliability. By integrating advanced materials and engineering precision, the SW16G bearing stands out as a cornerstone component, supporting innovative and sustainable practices across various sectors. As technology and material sciences continue to evolve, so too will the capabilities and applications of bearings, ensuring their essential role in machinery and manufacturing for years to come.

In summary, whether in automotive, aerospace, or manufacturing settings, the SW16G bearing's design offers significant advantages over traditional bearing technologies. Its combination of durability, low maintenance requirements, and versatility ensures it meets the demanding needs of modern industries. As we advance into an era defined by innovation and sustainability, the technology underpinning bearings like the SW16G will undoubtedly keep pace, driving improvements in efficiency, performance, and ultimately, the operational success of machinery across various domains.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!