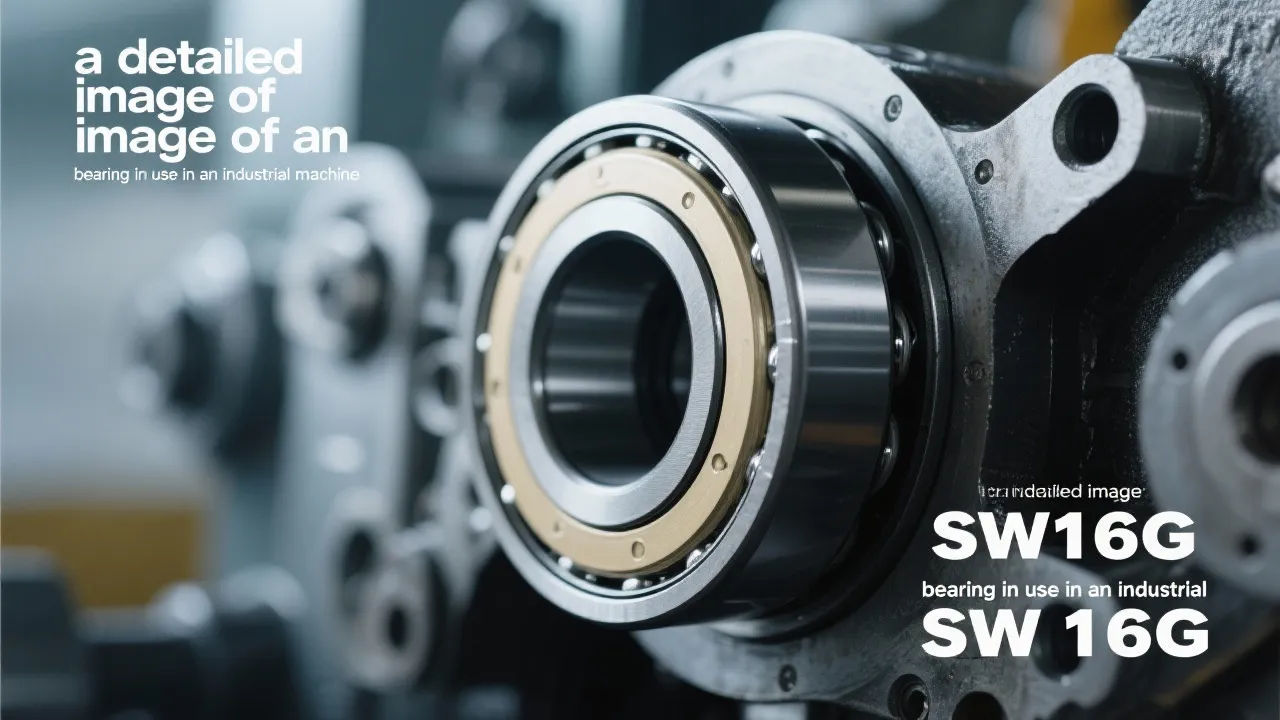

This comprehensive guide delves into the intricate world of SW16G bearings. Vital for machinery across diverse industries, these bearings are engineered to support radial and axial loads efficiently. Their robustness and precision make them indispensable components in mechanical systems. Here, we explore their characteristics, applications, and key considerations for selection and maintenance.

SW16G bearings are precision-engineered components crucial to the functioning of complex machinery. They are designed to efficiently support both radial and axial loads, making them integral to various industrial applications. Their unique design and construction provide significant benefits, such as reducing friction, enhancing machine performance, and extending equipment life. Bearings play an impactful role in the smooth operation of machines and mechanisms, particularly in high-speed and load-bearing applications. Understanding the characteristics of SW16G bearings contributes significantly to optimizing machinery performance across several industries.

Understanding the technical aspects of SW16G bearings is essential for selecting the right bearing for specific applications. Typically, these bearings are constructed from high-quality steel, ensuring durability and resistance to wear and corrosion. Their standard design includes an inner and outer ring, a cage, and a set of precision balls or rollers, which facilitate smooth rotational movement. Bearings are also classified into different types based on their design and application, each characterized by unique metrics like load ratings, clearance, lubrication features, and sealing options.

In addition to the material composition, SW16G bearings can vary in size, which is often designated by their dimensional specifications such as bore diameter, outer diameter, and width. Integrating these bearings into machinery impacts overall functionality, and therefore understanding these measurements is critical for proper installation and operation.

SW16G bearings are utilized in a variety of sectors owing to their adaptability and reliability. They are commonly employed in manufacturing equipment, automotive industries, and aerospace applications due to their ability to withstand high speeds and loads. Their precision and reliability also make them suitable for use in high-tech environments, such as robotics and automated systems. Several factors drive their application across diverse fields including precision requirements, load handling capabilities, and environmental conditions.

In the automotive sector, these bearings find their applications in vehicles' engines, transmissions, and wheel hubs, optimizing performance by reducing friction and enhancing fuel efficiency. In aerospace applications, the SW16G bearings are integral in supporting critical fastening mechanisms, landing gear systems, and engine components, where reliability and safety are of utmost importance.

| Application | Description |

|---|---|

| Automotive | Enhances performance in engines and transmission systems by reducing friction. |

| Aerospace | Supports critical components in engines, ensuring safety and reliability during flight. |

| Manufacturing | Integral in machines requiring high precision and load endurance. |

| Robotics | Facilitates smooth motion in robotic joints, ensuring high precision in operation. |

| Industrial Equipment | Used in conveyor systems and motors to improve workflow efficiency. |

| Medical Devices | Critical components in imaging machines and surgical tools, where precision is vital. |

| HVAC Systems | Enhances efficiency in fans and blowers, reducing energy consumption. |

Choosing the right SW16G bearing involves considering several factors. These include load capacity, speed capability, lubrication requirements, and environmental conditions. Compatibility with existing machinery dimensions is crucial, as is understanding the specific demands of the machine’s operation in terms of angular or radial stress. Furthermore, factors such as thermal expansion, operating temperature, and possible exposure to corrosive substances should influence the selection process to ensure the integrity and functionality of the bearing over time.

Load capacity is a core metric to evaluate, as each bearing has a defined maximum load it can handle without significant wear or failure. Speed capability pertains to how fast the bearing can rotate without overheating or degrading. Each application will have unique demands, and these parameters should guide the selection process. The right lubricant is critical to minimize contact friction and wear while serving to efficiently dissipate heat generated during operation. Different lubrication methods—grease, oil, or solid lubricants—impact bearing performance and lifespan, also guiding the selection of bearings.

Regular maintenance is key to prolonging the lifespan of SW16G bearings. This includes periodic inspections for wear and tear, ensuring proper lubrication, and promptly addressing any signs of malfunction such as noise or vibration. Failure to adequately maintain bearings can lead to early failure, decreased performance, and costly downtime. Following manufacturer guidelines for maintenance can significantly enhance the performance and durability of these bearings.

Scheduled maintenance practices can include periodic checks of operating noise, visual inspections of the bearing housing for lubricants, and assessing any changes in vibration patterns. Predictive maintenance, utilizing technologies such as vibration analysis or thermal imaging, can help in foreseeing potential malfunctions, allowing proactive adjustments or replacements to avoid unplanned downtime. Implementing effective maintenance strategies reflects an understanding of the operational importance of bearing performance and reliability.

One critical aspect of bearing performance is heat generation. Bearings operate under friction, which leads to heat production. Excessive heat can degrade lubrication, compromise bearing materials, and result in failure. Monitoring operating temperatures is essential, and bearings should be selected based on their operational heat limits, which can be influenced by factors such as speed and load. The heat dissipation capabilities of the surrounding assembly also affect bearing life. Employing bearing designs with optimized heat dissipation or using cooling systems can contribute to maintaining optimal bearing temperatures.

What is the typical lifespan of an SW16G bearing?

With proper maintenance, SW16G bearings can last anywhere from 5 to 10 years depending on the application and environmental conditions.

How do I know if a bearing needs replacement?

Indicators for replacement include unusual noise, increased vibration, and heat in the operating environment. If a bearing emits a grinding sound during operation, it may indicate internal damage requiring immediate attention.

Can SW16G bearings be used in low-temperature applications?

Yes, provided they are made from materials that can withstand low temperatures without compromising performance. Materials like stainless steel or specially coated components enhance performance across various temperature ranges.

What lubrication methods are recommended for SW16G bearings?

Depending on the application, grease or oil lubrication may be employed. Grease is often preferred for its ability to stay in place and protect the bearing from contaminants, while oil can provide better heat management.

How can I extend the life of SW16G bearings?

Regular maintenance, appropriate lubrication practices, and careful monitoring of operational conditions can significantly enhance the lifespan of SW16G bearings. Following manufacturer recommendations also plays a critical role in ensuring their effective functioning.

Understanding the different failure modes of bearings is essential in predicting and mitigating potential issues. Common failure modes include:

Each of these failure modes can significantly reduce bearing life and impact machinery performance negatively. Proactive maintenance and monitoring help in identifying these issues early, thus prolonging equipment reliability and efficiency.

As industries evolve, bearing technology is continuously advancing to meet changing demands and challenges. Innovations in materials and manufacturing techniques have led to the development of bearings that offer enhanced performance characteristics such as higher load capacities and lower friction coefficients. Some notable trends include:

SW16G bearings are essential to the efficiency and reliability of many industrial machines. Their ability to minimize friction and support heavy loads under various conditions makes them indispensable. Through understanding their specifications, diverse applications, and maintenance requirements, businesses can ensure they select the right bearings to support their machinery's performance and longevity. Moreover, staying abreast of technological advancements in bearing design and materials is crucial for optimizing operational excellence and maintaining competitiveness across various sectors.

In summary, working with SW16G bearings demands not only knowledge of their technical specifications but also a proactive approach to maintenance, careful selection based on application, and an awareness of potential failure modes and technological advancements. These factors collectively contribute to ensuring long-lasting performance, reliability, and safety in machinery applications across multiple industries.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!