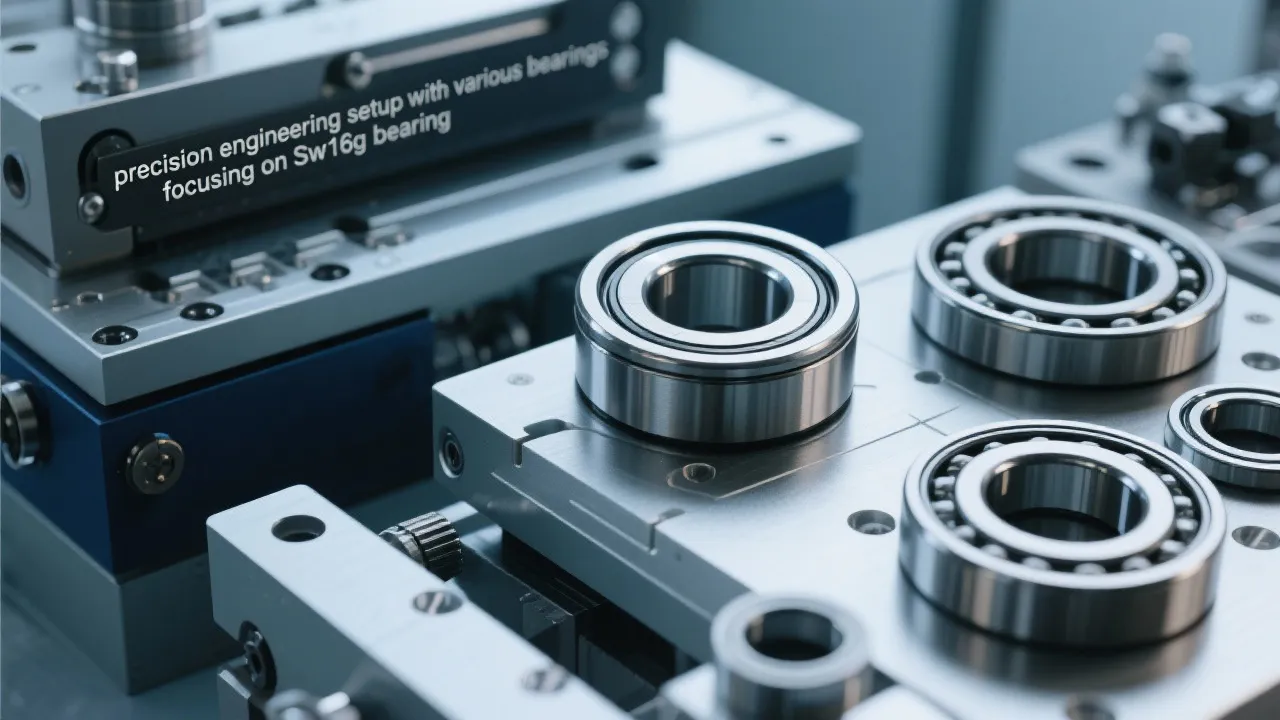

In the world of engineering and mechanical applications, bearings play a crucial role, and the Sw16g Bearing is no exception. This article delves into its essential aspects, highlighting the significance of Sw16g Bearing in supporting loads and reducing friction in machinery. A detailed exploration of its features and applications provides valuable insights for industry professionals and enthusiasts.

In the realm of mechanical engineering, bearings are indispensable components. They facilitate motion by minimizing friction between moving parts. Bearings are characterized by their ability to support both radial and axial loads while enabling smooth movement in various machinery. Among the various types of bearings, the Sw16g Bearing has gained notable attention due to its unique features and broad range of applications. This article aims to provide a comprehensive analysis of the Sw16g Bearing, exploring its critical attributes, benefits, and role in industrial settings.

The Sw16g Bearing is renowned for its durability and precision. It is specifically designed to support heavy loads while ensuring efficient rotational or linear movement in machinery. Its construction minimizes wear and tear, prolonging the lifespan of the equipment it supports. The Sw16g Bearing is typically made from high-quality materials, which enhance its resistance to environmental factors such as moisture and temperature fluctuations. One of the significant aspects of the Sw16g Bearing is its ability to operate effectively in various lubrication environments, highlighting its versatility.

The versatility of the Sw16g Bearing is evidenced by its widespread use across various industries. It is commonly found in automotive engines, industrial machinery, and even aerospace technology. This bearing is integral to ensuring smooth motion and reliability in high-demand environments. In the automotive sector, for instance, the Sw16g Bearing can be found in different components such as crankshafts and electric motors where handling high-speed rotations is necessary. Similarly, in industrial machinery, it is utilized in conveyor systems, pumps, and compressors, demonstrating its adaptability.

In the realm of aerospace technology, Sw16g Bearings are crucial for applications where high precision and reliability are paramount due to strict safety regulations and performance standards. These bearings are used in landing gear, engine components, and flight control systems where any failure could have critical consequences. Thus, the Sw16g Bearing's ability to function under harsh conditions while maintaining performance makes it an essential component in these high-stakes environments.

| Feature | Sw16g Bearing | Standard Bearing |

|---|---|---|

| Load Capacity | High | Moderate |

| Durability | Excellent | Good |

| Precision | Very High | High |

| Material Resistance | High | Variable |

In the above table, the Sw16g Bearing clearly distinguishes itself from standard bearings in several critical areas. Not only does it exhibit a higher load capacity, but its durability and precision make it a superior choice for demanding applications. Moreover, while standard bearings might contemplate materials like plastic or lower-grade metals, the Sw16g Bearing typically utilizes high-grade steel or composite materials designed to withstand harsh environmental influences.

To ensure the Sw16g Bearing operates at its top, consider the following conditions:

Q1: What are the main advantages of using Sw16g Bearings?

A: Their main advantages include high load capacity, reduced friction, exceptional durability, and precise performance in demanding environments. These features contribute significantly to the operations of various machinery, enhancing both efficiency and lifespan.

Q2: Can Sw16g Bearings be used in extreme temperatures?

A: Yes, they are designed to withstand a range of environmental conditions, but it's crucial to ensure they are suitable for the specific application. In many applications, particularly in aerospace and automotive sectors, specific grades of the Sw16g Bearing may be engineered to perform optimally in high or low temperature extremes.

Q3: What industries typically use Sw16g Bearings?

A: These bearings are widely used in the automotive, industrial machinery, and aerospace sectors due to their robustness and reliability. Additionally, sectors such as robotics, manufacturing automation, and even large-scale construction equipment have also adopted the Sw16g Bearing because of its efficiency and load handling capabilities.

To ensure continuous performance and longevity of the Sw16g Bearing, adopting effective maintenance practices is essential. These practices focus not only on the bearing itself but also on the larger system it operates within. Here are several best practices for maintaining Sw16g Bearings:

By adhering to these maintenance practices, operators can significantly extend the life of the Sw16g Bearing and maintain the overall efficiency of the machinery it supports. Consistency in maintenance helps ensure that the bearings are performing at peak efficiency and minimizes potential downtime caused by unexpected failures.

As industries continue to prioritize sustainability and environmental responsibility, the role of bearings, including the Sw16g Bearing, is critical in minimizing ecological footprints. Not only are the materials used in the Sw16g Bearings designed for durability, but many manufacturers also strive for sustainability in production. Here are some considerations regarding the environmental impact of bearings:

By choosing Sw16g Bearings designed with sustainability in mind, industries can contribute to a greener future while maintaining mechanical efficiency. A focus on eco-friendly practices not only enhances corporate responsibility but also appeals to an increasingly environmentally-conscious consumer base.

The bearing industry, including the realm of models like the Sw16g Bearing, is continuously evolving, driven by technological advancements and increasing demand for performance. The future of bearing technology will likely see several notable trends and developments, including:

As these trends unfold, it is crucial for engineers and manufacturers to remain updated on the latest advancements to leverage these innovations effectively. The adoption of new technologies can provide a competitive edge and enhance the functionality of machinery, including the utilization of Sw16g Bearings.

The Sw16g Bearing represents a sophisticated engineering solution, crucial for ensuring the efficient operation of a variety of mechanical systems. Its design and material composition facilitate long-lasting performance, making it an essential component in the toolkit of any engineer working in complex industrial landscapes. Understanding its benefits, optimal usage conditions, and application potential is paramount for professionals seeking to maximize machinery efficiency and durability.

Moreover, as industries keep evolving and the demand for sustainability rises, the future of bearing technology, particularly models like the Sw16g, promises to focus on advanced materials, smart technologies, and sustainability efforts that will reshape how these components are understood and utilized. By staying informed about these developments, engineers can help drive their industries toward more innovative, efficient, and environmentally-friendly practices.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!