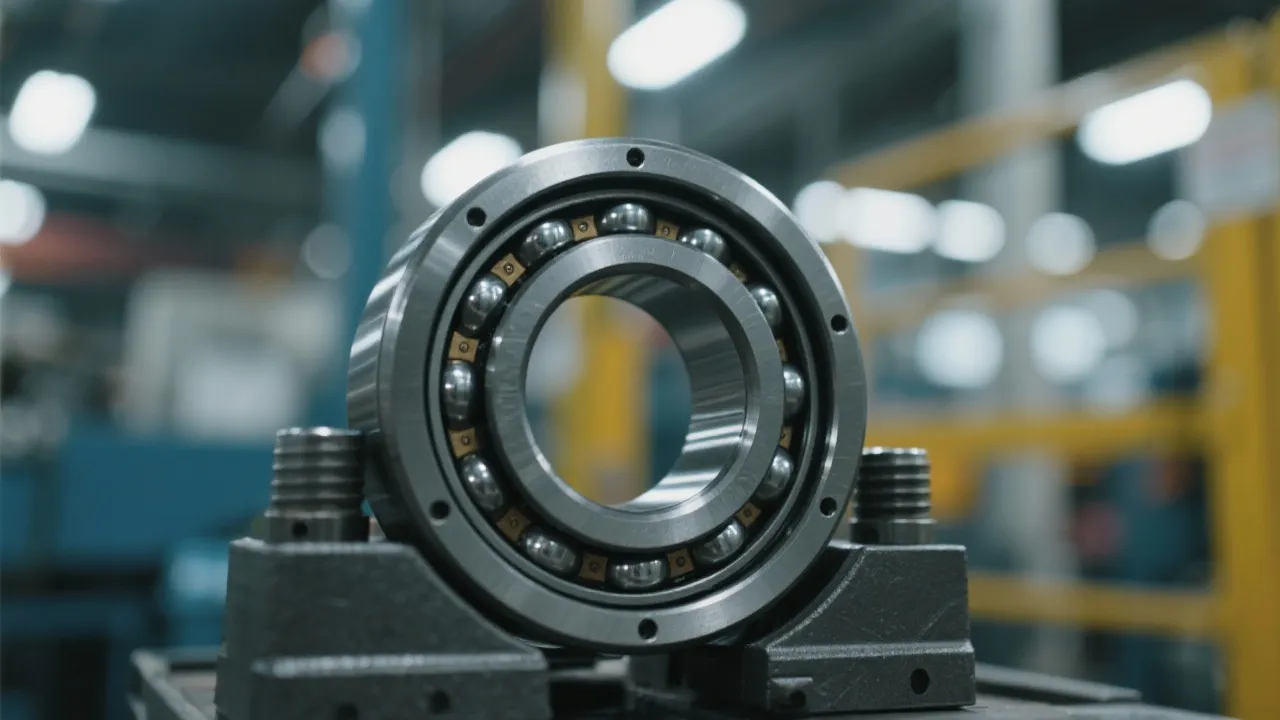

SW16G Bearings are essential components in various industries, known for their durability and efficiency. Widely used in machinery that requires high precision and load capacity, these bearings are integral in enhancing equipment performance. This article explores SW16G Bearings' significance, their applications, benefits, and industry insights, offering a comprehensive guide for both seasoned professionals and interested novices.

SW16G Bearings are widely recognized for their pivotal role in industrial applications, offering reliability and performance in machinery requiring high precision and durability. These bearings are engineered to minimize friction between components, significantly enhancing the longevity and efficiency of various equipment. With advancements in technology, the design and material of SW16G Bearings have been refined to ensure they meet the rigorous demands of modern machinery.

The primary benefits of SW16G Bearings lie in their meticulous design and construction, allowing for substantial load handling and smooth operation in high-stress environments. They are crafted from robust materials capable of withstanding extreme pressure, making them ideal for heavy-duty tasks across numerous sectors, including manufacturing, automotive, and aerospace industries. Additionally, the design of these bearings includes features such as enhanced sealing and superior surface finishes which contribute to reduced wear and lower maintenance needs.

Another significant advantage is their thermal stability, which allows them to perform well in environments with varying temperatures without compromising their structural integrity. This ensures consistency in performance, even when exposed to high temperatures commonly found in heavy machinery operations.

Moreover, SW16G Bearings are designed with noise reduction in mind, which is especially important in industries requiring precision and quiet operation, such as the aerospace sector. Their ability to operate silently improves working conditions and reduces the stress on both machines and workers.

SW16G Bearings find extensive use in sectors where reliability is paramount. From conveyor systems and industrial robotics to automotive parts and aerospace navigation, these bearings serve to reduce friction and wear, ensuring the seamless operation of machinery. Their application is crucial in maintaining the efficiency and productivity of equipment, thereby contributing to operational success.

The manufacturing industry, for instance, relies heavily on SW16G Bearings in automated machinery and assembly lines. Here, their performance directly impacts throughput and product quality. In the automotive industry, these bearings are integral to various components such as wheels, engines, and transmissions, where precision and durability are essential for vehicle safety and longevity.

In the aerospace industry, SW16G Bearings are utilized in both commercial and military aircraft for components where weight savings and performance are critical. The ever-increasing demand for lightweight, high-strength materials has pushed manufacturers to seek out advanced bearing solutions that can withstand the extreme conditions of flight.

Furthermore, SW16G Bearings are becoming more common in emerging technologies, including electric vehicles and renewable energy applications such as wind turbines. Their properties lend themselves well to systems needing robust performance while minimizing maintenance requirements.

As machinery in various industries becomes more sophisticated, demands for high-performance bearings like the SW16G have surged. Industry reports reveal a consistent growth in the bearing market, driven by advancements in technology and materials, which further enhance bearing capabilities. Understanding market trends and innovations can provide crucial insights for businesses seeking to maximize efficiency and performance through the strategic use of SW16G Bearings.

In recent years, the emphasis on sustainability and eco-friendly practices has also influenced the bearing market. Manufacturers are increasingly seeking to produce bearings that not only perform well but also have reduced environmental impacts. This includes the use of recyclable materials and processes that minimize waste.

Additionally, the rise of automation and smart manufacturing has led to the development of intelligent bearing solutions equipped with sensors that provide real-time data on performance and condition. These advancements allow operators to foresee potential failures and address issues proactively, minimizing downtime and operational costs.

Moreover, global economic trends, such as fluctuations in manufacturing output, have a direct impact on the bearing industry. As countries invest in infrastructure and technology, the need for high-performing bearings expands, driving further innovation and demand.

| Feature | SW16G Bearing | Standard Bearing |

|---|---|---|

| Load Capacity | High | Medium |

| Material | Reinforced Steel | Standard Steel |

| Durability | High | Moderate |

| Applications | Industrial, Aerospace, Automotive | General Machinery |

| Temperature Tolerance | Up to 200°C | Up to 100°C |

| Maintenance Frequency | Low | Medium |

| Friction Coefficient | Low | Medium |

This comparative analysis highlights the superior features of SW16G Bearings over standard alternatives, emphasizing their robustness and suitability for demanding applications. Understanding these specifications can guide industry professionals in selecting the right bearings for their specific needs, optimizing performance and safety.

Proper maintenance of SW16G Bearings is crucial to maximizing their lifespan and performance. Regular inspection for signs of wear and tear, ensuring proper lubrication, and timely replacement are essential practices. Employing these maintenance strategies not only enhances the operational efficiency of the bearings but also prevents costly downtimes and repairs.

One of the most critical aspects of maintaining SW16G Bearings is ensuring they are adequately lubricated. The choice of lubricant and the frequency of application can significantly affect the bearings' performance. It is advisable to use high-quality lubricants that are appropriate for the operating conditions, including temperature, load, and speed. Over-lubrication should also be avoided, as it can lead to increased friction and heat build-up.

Moreover, monitoring vibrations can serve as an early warning system for potential failures in bearings. Regularly checking for abnormal vibrations or sounds can help in detecting issues before they lead to significant damages. Vibration analysis tools can be useful for this purpose.

Environmental factors should also be considered in the maintenance routine. If the bearings are exposed to dust, moisture, or corrosive environments, measures should be taken to protect them. Protective seals and regular cleaning schedules can help mitigate these risks.

Lastly, maintaining accurate records of maintenance activities can aid in extending the life of the bearings. This includes documentation of inspections, lubrications, and changes made over time, providing valuable insights into the bearings' performance history and helping to identify trends or recurring issues.

SW16G Bearings are a crucial component for industries focusing on high performance and reliability. Their advanced design and durability make them indispensable for sustaining the efficiency of industrial applications. By understanding their benefits, applications, and maintenance requirements, businesses can leverage these bearings to achieve superior operational outcomes.

As industries continue to evolve with technology, the role of bearings will only become more prominent. Investing in quality, such as SW16G Bearings, can be a decisive factor for enterprises looking to enhance their performance and reduce downtime. Therefore, the strategic use of high-quality bearings is essential for gaining a competitive edge in the market.

This necessitates ongoing education and awareness about the latest advancements in bearing technology. By staying informed and adapting to changing industry standards, companies can optimize their equipment performance and ensure longevity and reliability, ultimately leading to sustained success in their respective fields.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!