The SW16G bearing serves as a critical component in various mechanical systems, providing essential support and reducing friction. These bearings are fundamental in ensuring the smooth operation and longevity of machinery. This article explores the intricacies of SW16G bearings, highlighting their uses, construction, and benefits to offer a comprehensive understanding for industry professionals and enthusiasts alike.

SW16G bearings are precision-engineered components designed specifically to provide the necessary support and motion affordable in diverse mechanical applications. These bearings play a pivotal role in minimizing friction, thereby enhancing the performance and longevity of machines. Understanding their structure, application, and advantages is crucial for engineers and operators who aim to optimize equipment efficiency.

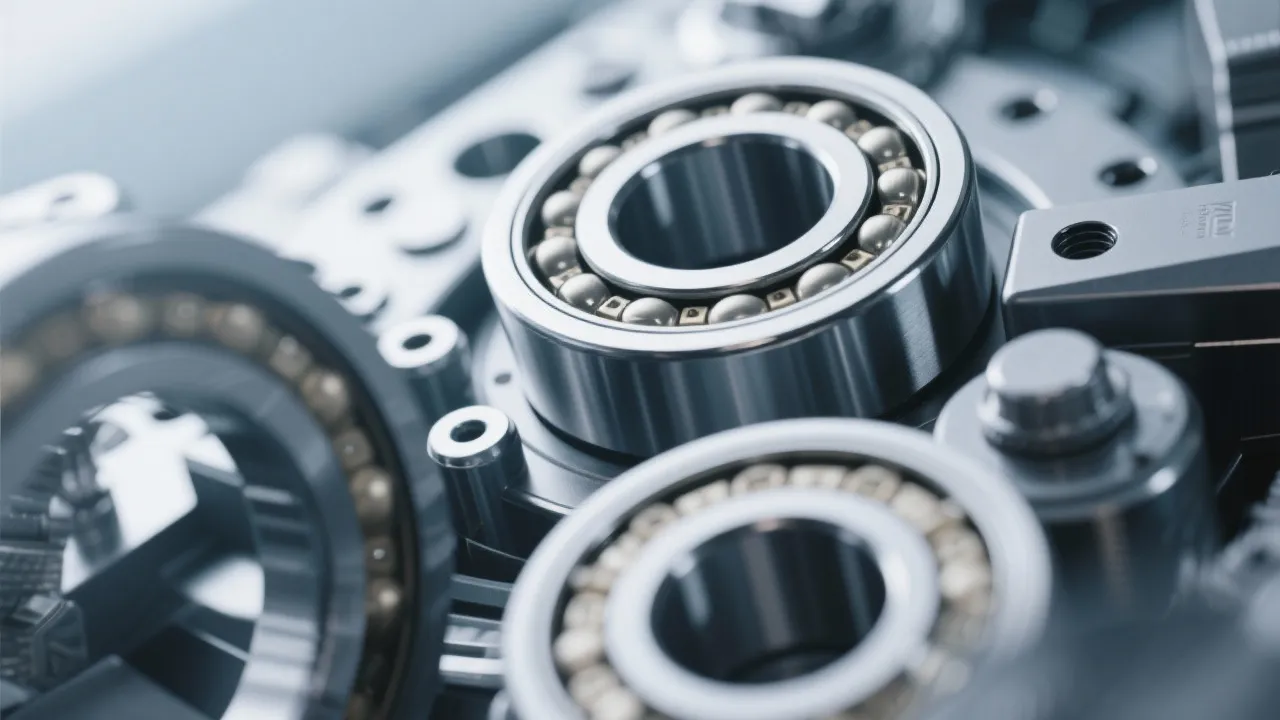

SW16G bearings are typically crafted from high-grade materials to withstand the pressures and environmental conditions they operate under. The composition generally includes hardened steel, which offers excellent durability and wear resistance. The steel is often treated with a corrosion-resistant coating to expand its application range, including in harsh and demanding environments.

In addition to steel, some SW16G bearings may incorporate composite materials or specialized lubricants that enhance performance characteristics. For instance, some may utilize a high-performance polymer cage, which can offer reduced weight and improved wear characteristics compared to traditional metal cages. This innovation in materials allows for better performance in specific applications, especially in areas where weight savings are critical, such as in aerospace or automotive sectors.

The versatility of SW16G bearings makes them indispensable in various sectors, including automotive, aerospace, manufacturing, and robotics. Their ability to support axial and radial loads while delivering smooth operation under high speeds makes them suitable for incorporation into gear systems, engines, and motors. By reducing wear and enhancing reliability, these bearings contribute significantly to the operational consistency of machinery.

Moreover, SW16G bearings have found applications in precision tools and medical devices, where exact tolerances and reliability are paramount. For instance, in robotic surgical instruments, the precise movement and reliability required are facilitated by the use of high-grade SW16G bearings. Their ability to maintain performance under repetitive motion and varying temperature conditions makes them a preferred choice for such high-stakes applications.

| Feature | Description |

|---|---|

| Material | High-grade, corrosion-resistant steel |

| Capacity | Can support both radial and axial loads effectively |

| Application | Utilized in automotive, aeronautics, manufacturing, and robotics |

| Maintenance | Requires regular lubrication and inspection to ensure longevity |

Mechanical reliability is at the heart of SW16G bearings’ advantages. The following aspects underscore their beneficial impact:

Besides these advantages, another crucial benefit of SW16G bearings is their adaptability to different lubrication regimes. Some applications may benefit from grease lubrication, while others might require oil lubrication to ensure seamless operation. The versatility in lubrication methods further enhances their usability across various industry sectors, making them an excellent choice for engineers seeking reliable solutions for their projects.

Proper maintenance is crucial to ensuring the functionality and performance of SW16G bearings. Regular inspections should be conducted to assess lubricant levels and detect wear or misalignment. It's also advisable to replace bearings at any sign of degradation to prevent machine damage and downtime.

The maintenance regimen should include periodic cleaning of the bearing assembly, particularly in environments that involve heavy dust and debris. Contaminants can lead to premature wear and bearing failure if not addressed. Additionally, using diagnostic tools that can assess vibration levels can help identify potential issues before they lead to catastrophic failure. Incorporating such predictive maintenance strategies can be a game-changer in prolonging the life of SW16G bearings.

The main components include the inner and outer ring, ball or roller elements, and a separator to maintain spacing between them. Each of these components must be manufactured to exact specifications to ensure the intended performance and reliability of the bearing.

Consider the load capacity, speed requirements, and environmental conditions of your application. Consulting with a specialist can ensure the top fit. Additionally, reviewing the manufacturer's technical data sheets can provide insights into the bearing's capabilities and potential limitations.

Yes, SW16G bearings are designed to endure a wide range of temperatures, making them suitable for various harsh environments. Some variants are specifically designed to perform exceptionally well in high-temperature scenarios, such as those encountered in automotive engines or aerospace applications.

The advancing technology in materials and manufacturing processes will significantly affect the evolution of SW16G bearings. New materials, including advanced ceramics and composites, may soon enter mainstream applications, enabling even greater load capacities and resistance to wear and tear. Additionally, improvements in manufacturing methods, such as additive manufacturing (3D printing), are likely to create opportunities for custom bearing designs tailored for specific applications.

Furthermore, the incorporation of smart technology into bearings, such as embedded sensors for monitoring condition and performance, will undoubtedly enhance their capabilities. These smart bearings can feed real-time data to maintenance teams, allowing for predictive analytics that can foresee failures before they occur, radically transforming the maintenance plans of machinery using SW16G bearings.

To illustrate the impact of SW16G bearings in real-world applications, here are some detailed case studies highlighting their benefits:

In an automotive manufacturing plant, the integration of SW16G bearings in assembly lines led to a marked improvement in production efficiency. By replacing traditional bearings with SW16G variants, the machinery experienced a 30% reduction in friction, facilitating smoother operations and faster assembly times. The lifespan of the machines was extended by over 25%, resulting in significant cost savings in downtime and maintenance.

The aerospace company recognized that the reliability of moving parts was paramount as they developed a new line of drones. By utilizing SW16G bearings in the propulsion systems, the project saw a significant increase in efficiency and performance during test flights. The bearings' ability to withstand extreme temperatures and variable loads proved essential in successfully meeting both safety and performance protocols, ultimately leading to enhanced customer satisfaction and reduced operational costs.

A robotics firm specializing in automated warehouse solutions integrated SW16G bearings in their robotic arms. These bearings allowed for high-speed precision movements, essential for reliability and efficiency in the sorting processes. The documented enhancements in speed led to a 40% improvement in sorting time and a better overall throughput of goods, validating the choice of SW16G bearings for such critical tasks.

In conclusion, SW16G bearings are a cornerstone component in modern engineering, providing essential stability and performance enhancement to machinery across industries. With appropriate maintenance and selection tailored to specific application needs, these bearings ensure operational efficiency and longevity. Through continuous innovation and integration of advanced technologies, the future of SW16G bearings promises not only to uphold the standards of mechanical engineering but to elevate them, contributing to even greater advancements in the world of applications that demand precision, reliability, and performance.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!