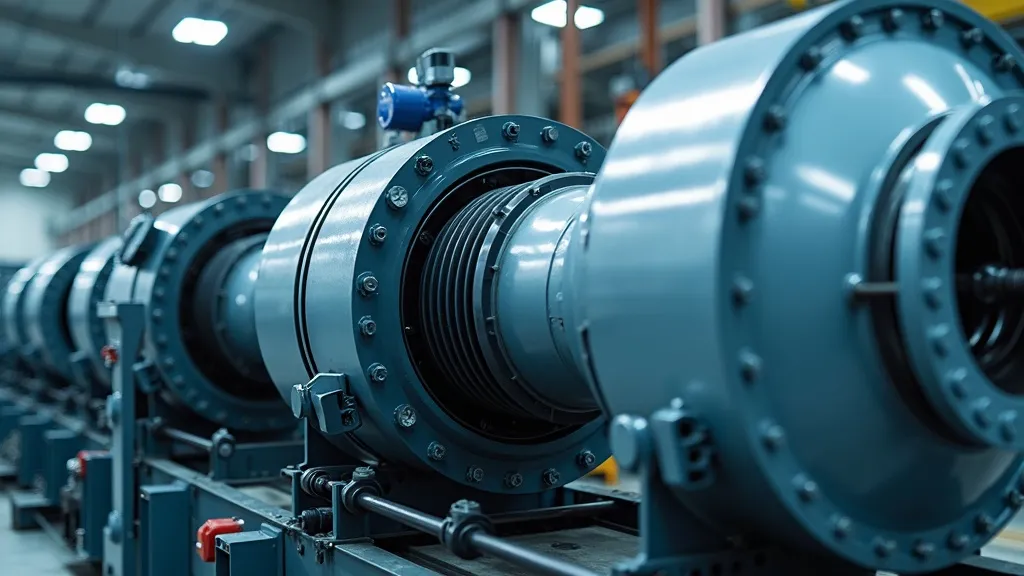

Regenerative blowers are vital components in various industrial applications, known for their efficiency in moving air and gases. These devices operate by using non-positive displacement to create pressure or vacuum, making them indispensable in industries such as wastewater treatment, pneumatic conveying, and more. Their versatility and reliability have cemented their place in modern manufacturing and processing environments.

In the realm of industrial equipment, regenerative blowers stand out due to their unique ability to move large volumes of air at low pressure. Unlike traditional fans or compressors, these blowers use a non-positive displacement method to create a flow of air or gas, making them ideal for applications that require continuous airflow. The innovation behind regenerative blowers lies in their design and operational efficiency, which allows for effective air movement without the complexities often associated with other types of blowers.

Regenerative blowers are not just limited to industrial applications; they have also found their place in various commercial settings, including aquariums, HVAC systems, and even in some residential applications. Their versatility is a significant factor contributing to their popularity across different sectors. As industries continue to seek out energy-efficient and reliable solutions for air movement, regenerative blowers remain a top choice due to their robust design and operational capabilities.

Regenerative blowers function based on a simple yet effective principle. Air enters the blower through an inlet and is captured in the space between the impeller blades. As the impeller rotates, air is accelerated outward and then directed back inward by the blower's housing. This process repeats, increasing pressure with each cycle, allowing the blower to generate a continuous flow at a consistent pressure. This method of operation enables regenerative blowers to achieve high volumes of airflow while maintaining low power consumption.

The impeller design plays a crucial role in the efficiency of regenerative blowers. Impellers are usually designed with multiple blades that help in creating a continuous flow of air. Each rotation of the impeller generates a vacuum that draws in air while simultaneously pushing out the already compressed air. The result is a smooth and consistent airflow that can be utilized in various applications, from cooling systems to pneumatic conveying. Furthermore, the compact design of these blowers allows for easy integration into existing systems without requiring extensive modifications.

These blowers are utilized across a broad spectrum of industries. They play a crucial role in wastewater treatment by providing aeration, ensuring that aerobic microorganisms can thrive and effectively break down organic matter. The aeration process is vital for maintaining healthy aquatic environments in treatment facilities, promoting the biological treatment of wastewater. In addition to aeration, regenerative blowers are essential in maintaining proper oxygen levels in aquaculture systems, which is critical for fish and other aquatic life.

Additionally, in pneumatic conveying systems, regenerative blowers are used to transport bulk materials through pipelines, a process critical in manufacturing and food processing. They facilitate the movement of powders, granules, and other bulk materials, ensuring efficient production processes. The ability to maintain consistent airflow is especially important in processes such as powder coating, where precise control over material flow is necessary for achieving quality finishes.

Regenerative blowers are also found in vacuum packaging machines, where they help in removing air from packages to extend the shelf life of perishable products. This application demonstrates the versatility of regenerative blowers in both air-moving and vacuum applications. In the food industry, maintaining the integrity and quality of products is paramount, and regenerative blowers play a vital role in achieving this goal.

One of the primary advantages of regenerative blowers is their low maintenance requirements. With fewer moving parts compared to other types of blowers, they offer enhanced reliability and longevity. This is particularly beneficial in industrial settings where equipment downtime can lead to significant financial losses. Furthermore, their ability to operate efficiently in both pressure and vacuum applications without the need for lubrication makes them a preferred choice in environments where contamination must be minimized. This feature is especially important in applications within the food and pharmaceutical industries, where hygiene standards are stringent.

Another advantage is their compact design, which allows them to fit into tight spaces and be easily integrated into existing systems. This flexibility can reduce installation costs and time, making them an attractive option for businesses looking to optimize their operations. Additionally, regenerative blowers operate quietly compared to other types of blowers, contributing to a better working environment. This noise reduction can enhance employee comfort and productivity, particularly in workplaces where noise levels are a concern.

Moreover, regenerative blowers can handle a variety of airflow requirements, making them suitable for a wide range of applications. Their ability to provide a steady flow of air at low pressure is advantageous in processes that require gentle handling of materials, preventing damage or degradation. This versatility further solidifies their position as a staple in many industrial applications.

| Type | Advantages | Disadvantages |

|---|---|---|

| Regenerative Blower | Low maintenance, versatile, efficient in low-pressure applications | Not suitable for high-pressure demands |

| Centrifugal Blower | High airflow, can handle varying flow rates | Generally more expensive, complex design |

| Positive Displacement Blower | Suitable for high pressure, precise control | Higher maintenance, noisier operation |

When comparing regenerative blowers to centrifugal blowers, one of the key differences is the design and method of operation. Centrifugal blowers are designed for high airflow applications and can handle varying flow rates, making them ideal for larger-scale operations. However, they are generally more expensive and have a more complex design, which can lead to higher maintenance costs.

On the other hand, positive displacement blowers are adept at delivering high pressures and offer precise flow control, making them suitable for applications that require specific pressure settings. However, they tend to have higher maintenance needs due to their more intricate mechanics and can operate at higher noise levels, which can be a disadvantage in certain environments.

Typically, a regenerative blower can last anywhere from 20,000 to 30,000 hours of operation, depending on the application and maintenance practices. Regular maintenance, such as checking for debris in the inlet and ensuring that the impellers are clean, can extend the lifespan of the blower significantly.

While they are primarily designed for dry applications, certain models are equipped with features that allow them to handle moisture-laden air. It’s crucial to select the right blower for such environments, as excessive moisture can lead to corrosion and damage over time. Manufacturers often provide specifications on the acceptable moisture levels for their blowers, and it is advisable to follow these guidelines to ensure optimal performance and longevity.

Yes, regenerative blowers are known for their energy efficiency, especially in applications where constant airflow is required. They consume less power compared to other types of blowers with similar output. This energy efficiency translates into lower operational costs, making them an attractive option for businesses aimed at reducing their overall energy consumption. Additionally, the low maintenance needs further enhance their cost-effectiveness over time.

When selecting a regenerative blower, it is essential to consider factors such as the required airflow rate, pressure range, application environment, and noise levels. Understanding the specific needs of your application will help in choosing the right blower model. Additionally, considering the blower's efficiency ratings and maintenance requirements can contribute to better long-term performance and reliability. It’s also beneficial to consult with manufacturers or suppliers to gain insights into the best options available for your needs.

Common maintenance practices for regenerative blowers include regular inspections to check for leaks and ensure that the air intake is clear of debris. Cleaning the impeller and housing periodically can prevent buildup that may affect performance. Monitoring vibration levels and noise can also provide early indicators of potential issues. Furthermore, checking the electrical connections and motor function is crucial for maintaining optimal operation. Following the manufacturer's recommended maintenance schedule can help in prolonging the life of the blower and ensuring its efficient performance.

Regenerative blowers have proven to be indispensable in various industries due to their efficiency, reliability, and low maintenance needs. As technology advances, these blowers continue to evolve, offering even more capabilities and features that cater to the growing demands of modern industrial applications. For companies looking to optimize their processes, investing in a high-quality regenerative blower can offer significant benefits. The ability to provide continuous airflow at low pressure, coupled with energy efficiency, makes these blowers a valuable asset in any operational setup.

As industries become increasingly focused on sustainability and cost-effectiveness, the role of regenerative blowers is likely to grow even further. Their adaptability to a wide range of applications, from environmental management to manufacturing, positions them as a key component in the future of industrial equipment. Businesses that embrace the advantages of regenerative blowers will not only enhance their operational efficiency but also contribute to a more sustainable and environmentally friendly approach to industrial processes.

In conclusion, understanding the principles, advantages, and applications of regenerative blowers is crucial for making informed decisions in industrial settings. Whether you are involved in wastewater treatment, pneumatic conveying, or any other application that requires reliable airflow, regenerative blowers offer a solution that combines efficiency, durability, and low environmental impact. As the demand for innovative industrial solutions continues to rise, regenerative blowers are set to play a pivotal role in shaping the future of air movement technology.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!