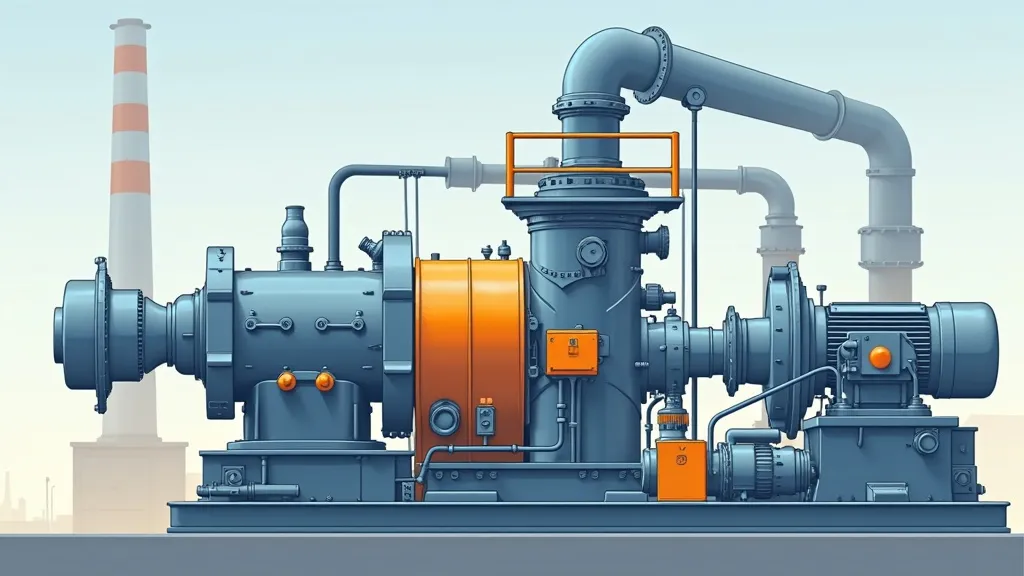

A regenerative blower is a critical component in various industrial applications, known for its efficiency in handling air and gas movement. Unlike traditional blowers, regenerative blowers offer high performance with minimal maintenance. They are widely used in industries such as wastewater treatment, chemical processing, and pneumatic conveying due to their durability and versatility.

Regenerative blowers are essential devices in numerous industrial applications, offering an efficient and reliable solution for air and gas movement. These blowers are renowned for their capability to handle significant volumes while maintaining high pressure, making them ideal for a wide range of uses, including wastewater treatment, chemical processing, and pneumatic conveying. As industries evolve and demand continues to rise for more efficient and sustainable technologies, regenerative blowers stand out as a crucial component in the quest for improved operational efficiency.

Understanding regenerative blowers also means acknowledging their role in energy conservation and environmental impact. With the increasing pressure on industries to reduce their carbon footprint, the energy-efficient design of regenerative blowers becomes a significant advantage. They not only help in reducing operational costs but also contribute to a greener environment, making them a preferred choice for many applications.

Regenerative blowers operate on the principle of creating a vortex that regenerates air pressure. The blower consists of an impeller with numerous blades that rotate within a housing. As air enters the blower, it is channeled through the impeller blades, where it gains velocity and pressure. This process is repeated, or "regenerated," multiple times as the air circulates through the blower, resulting in a stable and continuous flow.

The mechanism of operation can be better understood by considering the design of the impeller and the housing. The impeller’s blades are designed to create a spiral motion that not only moves air but also compresses it. This unique method of air movement allows regenerative blowers to achieve high pressure with relatively low energy consumption, which is a significant advantage over traditional blower designs.

One of the standout features of regenerative blowers is their ability to deliver high performance with minimal maintenance. They are designed to operate silently, which is a significant advantage in environments where noise reduction is critical. Moreover, regenerative blowers are compact and easy to install, offering flexibility in various industrial settings.

These blowers are also known for their durability and reliability. Constructed with high-quality materials, regenerative blowers can withstand harsh operating conditions and have a long service life, which reduces the need for frequent replacements and contributes to lower total cost of ownership. Additionally, their simple design often allows for easier troubleshooting and repair compared to more complex blower systems.

| Feature | Advantage |

|---|---|

| High Efficiency | Delivers consistent performance with low energy consumption. |

| Low Maintenance | Requires minimal upkeep, reducing operational costs. |

| Noise Reduction | Operates quietly, making it suitable for noise-sensitive environments. |

| Compact Design | Easy to install in various industrial setups. |

| Durability | Built to withstand demanding conditions, ensuring longevity. |

| Simple Operation | Ease of use and maintenance, resulting in reduced training time for operators. |

Regenerative blowers are versatile and find applications across numerous industries. In wastewater treatment, they are used to supply air for aeration processes, essential for the breakdown of organic matter. This process enhances the biological treatment of wastewater, promoting the growth of aerobic bacteria that digest pollutants, thus significantly improving water quality.

In the chemical industry, these blowers facilitate the movement of gases and vapors, playing a critical role in various processes such as mixing, drying, and material handling. Their ability to maintain consistent pressure is vital in applications where precise gas flow is required, ensuring that chemical reactions proceed efficiently and safely.

Additionally, regenerative blowers are employed in pneumatic conveying systems to transport materials efficiently. They are used to move granular and powder materials through pipelines, which is a common practice in industries such as food processing, plastics, and pharmaceuticals. Their capacity to handle a wide range of materials and their ability to maintain pressure over long distances make them indispensable in these applications.

Furthermore, regenerative blowers are also utilized in vacuum packaging machines, providing the suction needed to remove air from packaging, thus extending the shelf life of perishable goods. In the automotive industry, they assist in the drying processes of painted surfaces and in the application of coatings, where controlled airflow is critical for achieving high-quality finishes.

Selecting the appropriate regenerative blower depends on various factors, including the required airflow, pressure, and specific application needs. Consulting with industry experts can help ensure the right blower is chosen for your particular application, maximizing efficiency and performance. It is essential to consider the compatibility of the blower with the existing systems and the specific requirements of the materials being handled.

When assessing the airflow requirements, it is crucial to analyze the volume of air needed during peak operation, as well as the pressure requirements to ensure optimal performance. Additionally, the operating environment must be taken into account; for instance, if the blower will be exposed to corrosive substances or extreme temperatures, materials and designs that can withstand such conditions should be prioritized.

Another important consideration is the noise level of the blower, especially in environments where noise reduction is crucial for compliance with regulations or for the comfort of workers. Selecting a blower designed for quiet operation can enhance workplace safety and productivity.

Lastly, evaluating the maintenance needs and availability of replacement parts is vital to ensure long-term reliability and cost-effectiveness. Understanding warranty options and support services from manufacturers can also help in making an informed decision.

What is a regenerative blower used for?

Regenerative blowers are used for moving air and gases in applications such as wastewater treatment, chemical processing, and pneumatic conveying. They are also utilized in vacuum packaging, material drying, and various other industrial processes where controlled airflow is critical.

How does a regenerative blower differ from a traditional blower?

Unlike traditional blowers, regenerative blowers use vortex technology to regenerate air pressure, providing higher efficiency and consistent performance. Traditional blowers may rely on positive displacement or centrifugal forces, which can lead to greater energy consumption and less efficient operation in certain applications.

Are regenerative blowers noisy?

No, they are designed to operate quietly, making them suitable for environments where noise reduction is important. Many modern regenerative blowers are engineered with sound-dampening features to minimize noise pollution, which can enhance the overall work environment.

What maintenance is required for a regenerative blower?

Regenerative blowers require minimal maintenance, primarily involving regular inspections and cleaning to ensure optimal performance. It is advisable to check for any signs of wear on the impeller and housing, as well as to monitor the air filters if applicable. Keeping the blower clean and free from obstructions is key to maintaining its efficiency.

As industries face increasing pressure to lower their energy consumption and carbon emissions, the energy efficiency of regenerative blowers becomes a significant selling point. These blowers are engineered to operate with minimal energy waste, often achieving higher efficiencies than traditional blowers. This is particularly important in large-scale operations where even small improvements in efficiency can lead to substantial cost savings over time.

In addition to energy efficiency, regenerative blowers contribute to environmental sustainability by enabling processes that reduce waste and pollution. For instance, in wastewater treatment, enhanced aeration processes facilitated by regenerative blowers improve the efficiency of biological treatment, leading to cleaner effluents being released into the environment. This not only supports regulatory compliance but also contributes to the overall health of ecosystems.

Moreover, the compact design of regenerative blowers often requires less space than traditional blower systems, allowing for more efficient use of facility layouts. This can lead to reduced construction costs and a smaller environmental footprint for new installations. The ability to fit these blowers into existing systems without significant modifications further enhances their appeal for companies looking to upgrade their equipment while minimizing disruption to operations.

Looking ahead, the future of regenerative blowers appears promising as industries continue to prioritize efficiency and sustainability. Advances in materials science and engineering are likely to lead to even more efficient designs, potentially allowing for higher pressures and flow rates while maintaining or even reducing energy consumption.

Additionally, the integration of smart technology into regenerative blower systems can enhance their performance and reliability. For example, incorporating sensors and IoT technology can enable real-time monitoring and predictive maintenance, helping operators identify potential issues before they lead to failures. This proactive approach can significantly reduce downtime and maintenance costs, further enhancing the overall efficiency of operations.

As industries increasingly embrace automation and digitalization, regenerative blowers will continue to adapt to meet the evolving needs of various sectors. Their versatility and reliability make them a key player in the future of industrial air and gas movement solutions.

In conclusion, regenerative blowers are a vital component in modern industrial operations, offering efficiency, flexibility, and reliability. By understanding their operation and benefits, industries can leverage these devices to enhance productivity and sustainability. With their ability to operate quietly, require minimal maintenance, and adapt to various applications, regenerative blowers are poised to remain an essential tool for achieving operational excellence in a wide range of industrial settings.

As technology progresses and environmental considerations become increasingly important, regenerative blowers will likely play an even more critical role in helping industries navigate the challenges of the future. By investing in high-quality regenerative blowers and optimizing their use, businesses can ensure they are well-equipped to meet the demands of an ever-evolving marketplace.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!