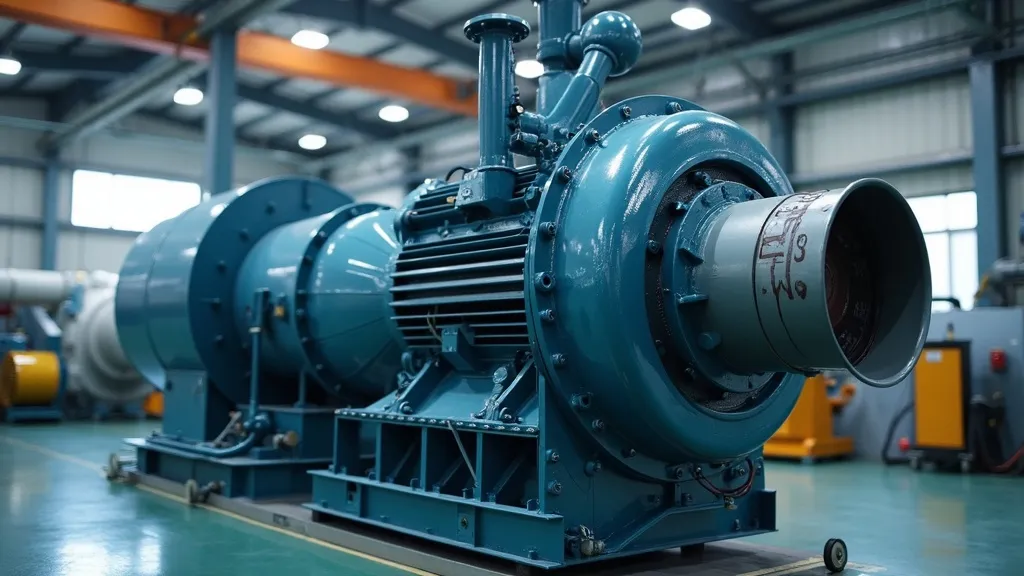

Regenerative blowers are integral to various industrial applications due to their efficiency and reliability. These devices, also known as side channel blowers, use a non-positive displacement mechanism to move air or gas, providing a continuous flow of air at different pressure levels. Their versatility and durability make them a preferred choice across diverse industries, from wastewater treatment to pneumatic conveying systems.

Regenerative blowers, often called side channel blowers, are essential components in numerous industrial processes. They operate using a non-positive displacement mechanism, which allows them to generate a continuous flow of air or gas at varying pressure levels. This unique capability has made regenerative blowers indispensable in applications such as wastewater treatment, pneumatic conveying, and vacuum lifting systems. Their design and functionality cater to a variety of industrial needs, making them a preferred choice across many sectors.

In addition to their widespread use in industrial applications, regenerative blowers also play a crucial role in some specialized sectors such as aquaculture, where they help maintain optimal oxygen levels in water, and in the food packaging industry, where they assist in creating vacuum seals. The adaptability of regenerative blowers not only highlights their importance but also points to the ongoing innovations that drive their development, ensuring that they meet the evolving demands of the market.

The operational principle of a regenerative blower is based on the creation of a vortex. As air enters the blower, it is accelerated by the impeller, which spins it outward and back toward the base of the blades. This action creates a regenerative air flow, hence the name. The continuous cycle of acceleration and circulation leads to high pressure and vacuum capabilities, making these blowers highly efficient and reliable.

Regenerative blowers typically consist of an impeller, diffuser, and housing. The impeller is mounted on a shaft and is powered by an electric motor. The design of the impeller allows for air to be drawn in from the atmosphere and expelled at a higher pressure. The air is then directed through the diffuser, which helps convert the kinetic energy of the air into pressure energy. This process is repeated continuously, providing a steady flow of air.

The efficiency of regenerative blowers is often attributed to their unique design. Unlike traditional blowers that may rely on positive displacement, regenerative blowers utilize a series of rotating blades that create a vacuum effect, allowing them to generate a consistent flow of air with minimal energy consumption. This design not only enhances operational efficiency but also extends the lifespan of the blower, making it a cost-effective solution for many applications.

Regenerative blowers are versatile and find applications in a variety of industries. In wastewater treatment plants, they are used for aeration, ensuring that bacteria have the oxygen needed to break down waste. This process is vital for the treatment of sewage and industrial effluents, contributing to environmental sustainability and public health.

In the pneumatic conveying industry, blowers transport materials through pipelines. The ability to move bulk materials, such as powders, granules, and pellets, efficiently and economically makes regenerative blowers a key component in manufacturing and processing facilities. Additionally, they are employed in vacuum lifting and packaging systems, where precise and steady airflow is crucial for maintaining product integrity and efficiency in operations.

Other notable applications include their use in material handling systems, where they facilitate the movement of lightweight materials, and in the electronics industry, where they assist in cooling processes. Their role in creating a controlled atmosphere in clean rooms and laboratories further underscores the versatility of regenerative blowers. Furthermore, regenerative blowers are instrumental in various medical applications, including ventilators and gas delivery systems, highlighting their importance in health care and emergency services.

The primary advantages of regenerative blowers include their robust design and longevity. They require minimal maintenance due to their oil-affordable operation, which eliminates the risk of contamination. This makes them ideal for applications where air purity is essential, such as in food processing and pharmaceuticals. Their quiet operation and high-performance efficiency also make them an attractive option for industries looking to optimize processes and reduce noise pollution.

Moreover, regenerative blowers are known for their compact size and lightweight design, allowing for easier installation and integration into existing systems. This is particularly beneficial for facilities with space constraints or where retrofitting is necessary. The energy efficiency of regenerative blowers also leads to lower operational costs, contributing to overall savings for companies that utilize them over time.

The adaptability of regenerative blowers to different environments and requirements further enhances their appeal. They can be tailored to meet specific industry needs, whether it’s customizing the blower for higher efficiency operations or adjusting it for specific pressure and flow rates. Their ability to handle varying loads and adapt to changing operational demands adds to their value as a reliable component in industrial processes.

| Blower Type | Advantages | Disadvantages |

|---|---|---|

| Regenerative Blower | High efficiency, low maintenance, oil-affordable operation | Limited to moderate pressure applications |

| Rotary Vane Blower | High pressure capability, well-suited for high-volume applications | Requires frequent maintenance, noisier operation |

| Centrifugal Blower | High flow rate, suitable for large volumes, efficient at high speeds | Lower pressure output, larger footprint, can be less efficient at low flow rates |

| Positive Displacement Blower | Consistent flow rate, excellent for high-pressure applications | Higher maintenance needs, can be more expensive to operate |

Understanding the differences between these types of blowers is crucial for selecting the most appropriate one for a specific application. While regenerative blowers excel in energy efficiency and low maintenance, rotary vane blowers are often preferred for high-pressure needs. Similarly, centrifugal blowers are ideal for applications requiring high flow rates, while positive displacement blowers offer consistent performance at higher pressure levels. Each type has its unique characteristics, and the choice largely depends on the operational requirements and constraints of the application.

When selecting a regenerative blower, it is crucial to consider factors such as the required airflow rate, pressure, and the environmental conditions of the application. It is also important to evaluate the blower's energy efficiency and noise levels to ensure it meets the specific needs of your operation.

Additionally, understanding the specific requirements of your process is vital. For instance, if the application involves handling delicate materials, you may prioritize blowers with a gentle airflow to avoid damage. Conversely, if you're working in a high-temperature environment, selecting a blower built with heat-resistant materials is essential. Consulting with experienced manufacturers or suppliers can provide valuable insights and recommendations tailored to your specific needs.

Furthermore, it’s important to take into account the installation space available. Some regenerative blowers are designed to fit into tight spaces, while others may require more room for maintenance and operation. Effective planning ensures that the chosen blower integrates seamlessly into existing systems without causing disruptions.

Finally, consider the long-term operational costs, including energy consumption and maintenance. While the initial investment may be significant, the total cost of ownership should be evaluated, taking into account potential savings from energy efficiency and reduced maintenance needs over time.

What maintenance do regenerative blowers require?

Regenerative blowers are designed for minimal maintenance. Regular inspection of the impeller and housing for wear and tear is recommended, along with ensuring that the inlet and outlet are free of obstructions. While the blowers do not require oil changes, keeping the air filters clean and ensuring that the blower is free from dust and debris will enhance its performance and longevity.

Can regenerative blowers handle corrosive gases?

While regenerative blowers are robust, handling corrosive gases may require blowers with special coatings or materials to prevent damage. It's essential to consult with the manufacturer for applications involving corrosive substances. Many manufacturers offer options that include corrosion-resistant materials or coatings that can enhance the blower's durability when used in challenging environments.

Are regenerative blowers energy efficient?

Yes, regenerative blowers are energy efficient due to their design, which minimizes energy losses. They are particularly effective in applications requiring consistent airflow and moderate pressure. The energy efficiency of these blowers can lead to significant cost savings over time, particularly in applications where they run continuously or for extended periods.

What factors influence the performance of a regenerative blower?

Several factors influence the performance of a regenerative blower, including the impeller design, the speed of operation, and the overall system configuration. The material of the blower and environmental conditions, such as temperature and humidity, also play a role in its efficiency and longevity. When assessing performance, it's vital to consider both the blower specifications and the requirements of the system it will be integrated into.

How do I ensure optimal performance from my regenerative blower?

To ensure optimal performance, regular maintenance is key. This includes checking for blockages, cleaning air filters, and ensuring that the blower is operating within its designed parameters. Additionally, monitoring the blower's performance metrics, such as airflow and pressure, can help identify any potential issues before they become significant problems. Keeping the blower in a clean environment and ensuring proper ventilation will also contribute to its efficient operation.

In conclusion, understanding the operational mechanics and advantages of regenerative blowers can significantly impact the efficiency and reliability of industrial processes. Their versatile nature and robust performance make them a valuable asset in various applications, supporting industries in achieving optimal operational standards. As technology advances, regenerative blowers continue to evolve, incorporating new materials and innovations that enhance their performance and adaptability in a wide range of applications.

With the ongoing development in blower technology and a growing focus on sustainability, regenerative blowers are likely to see expanded use in industries aiming to improve their environmental footprint while maintaining high operational efficiency. The investment in regenerative blowers can lead to more streamlined processes, lower energy consumption, and ultimately, enhanced productivity across various sectors.

The future of regenerative blowers looks promising, particularly as industries increasingly prioritize energy efficiency and sustainability. As environmental regulations tighten and the demand for cleaner technologies grows, regenerative blowers are well-positioned to meet these challenges. Manufacturers are actively exploring advancements in materials and designs that enhance the efficiency and performance of these blowers, focusing on reducing energy consumption while maintaining high output levels.

Moreover, the integration of smart technology and automation into regenerative blowers is expected to revolutionize how these systems operate. The application of sensors and IoT technology can provide real-time monitoring and feedback, allowing operators to optimize performance and anticipate maintenance needs proactively. This shift towards smart manufacturing and automation aligns with industry trends, emphasizing the importance of predictive maintenance and operational efficiency.

Furthermore, as the global market continues to evolve, regenerative blowers are likely to find new applications in emerging sectors such as renewable energy, where they can be used in processes like biomass handling or aeration in algae production systems. The adaptability of regenerative blowers means they can be tailored to fit the specific requirements of these new industries, further broadening their market appeal.

As the landscape of industrial processes changes, regenerative blowers will undoubtedly play a pivotal role in helping companies meet their operational goals while adhering to sustainability commitments. The ongoing research and development within this field will ensure that regenerative blowers remain a relevant and valuable solution for a wide range of applications, paving the way for more efficient and environmentally friendly industrial practices.

In summary, regenerative blowers stand out for their versatility, efficiency, and reliability across various industries. Their ability to adapt to different applications and environmental conditions makes them a cornerstone technology in many sectors. As industries continue to innovate and evolve, regenerative blowers will likely remain at the forefront of technological advancements, supporting operational excellence and sustainable practices in the years to come.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!