Regenerative blowers are vital in various industries, offering efficient airflow solutions for numerous applications. They function by recirculating air to generate pressure, making them ideal for tasks requiring consistent air movement. The technology behind regenerative blowers allows them to operate with minimal noise and maintenance, making them a preferred choice for businesses seeking reliability and efficiency.

In the realm of industrial machinery, regenerative blowers stand out for their efficiency and versatility. They are engineered to handle a wide range of applications, from wastewater treatment to pneumatic conveying. These devices operate on the principle of air recirculation, generating pressure by spinning air multiple times through impeller blades, unlike traditional blowers that rely on single-stage compression. This unique design allows regenerative blowers to achieve superior performance, making them a preferred choice for many industries. In this article, we will delve deeper into the workings of regenerative blowers, their applications, advantages, and considerations for selection, providing a comprehensive understanding of this essential industrial equipment.

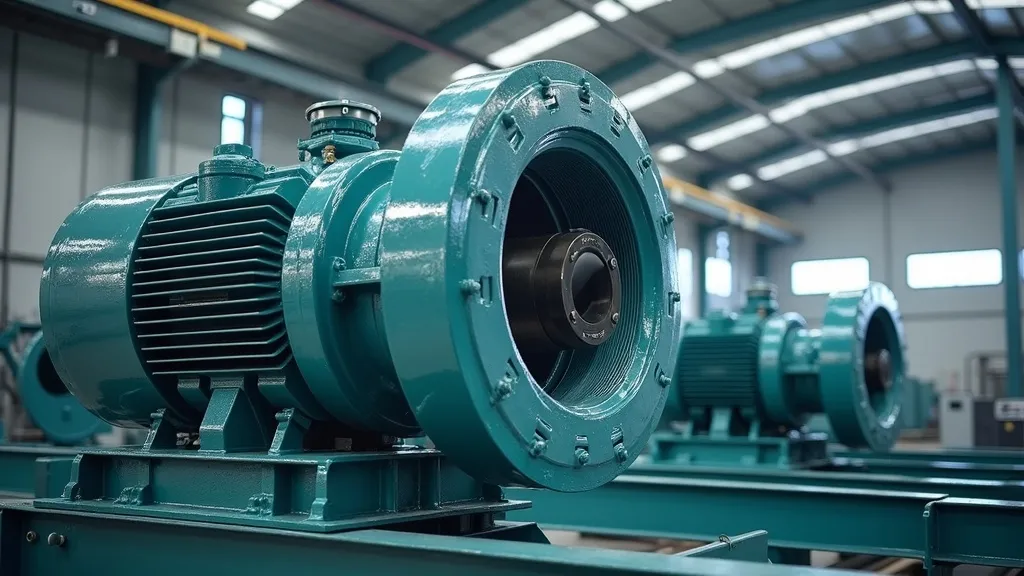

At the heart of a regenerative blower is the impeller, which is driven by an electric motor. As the impeller rotates, it pulls air into the blower and moves it along the vanes of the impeller. This motion creates a vortex, with air being cyclically recirculated, thereby increasing the pressure. The process is highly efficient, allowing regenerative blowers to produce consistent airflow with minimal energy consumption. The design of the impeller and the casing are critical in determining the efficiency of the blower. The impeller typically features a series of blades that are angled to facilitate the movement of air, while the casing is designed to minimize turbulence, ensuring a smooth flow of air throughout the system.

Regenerative blowers operate in a way that is distinct from other types of blowers. They utilize a multi-stage design that enhances their performance. Each stage of the impeller adds to the pressure of the air, allowing for higher pressures to be achieved without the need for complex multi-stage compression processes seen in traditional blowers. This multi-stage operation is what gives regenerative blowers their name; they regenerate the energy within the airflow through continuous recirculation. This unique mechanism not only boosts efficiency but also contributes to the longevity of the equipment, as the wear and tear on moving parts is significantly reduced.

Regenerative blowers are employed in various sectors, including:

Regenerative blowers offer several benefits that make them an attractive choice for industrial applications:

| Type of Blower | Energy Efficiency | Noise Levels | Maintenance Requirements | Pressure Range |

|---|---|---|---|---|

| Regenerative Blower | High | Low | Minimal | Up to 10 psi |

| Positive Displacement Blower | Moderate | High | Regular | Up to 15 psi |

| Centrifugal Blower | Variable | Moderate | Moderate | Variable |

When choosing a regenerative blower, it is essential to consider the following factors:

Regenerative blowers offer a compelling solution for industries seeking efficient and reliable airflow systems. Their unique design and ability to handle diverse applications make them a valuable asset in various sectors. By understanding their functionality, benefits, and selection criteria, businesses can optimize their operations and achieve superior performance with regenerative blowers. As industries continue to evolve, the demand for energy-efficient and versatile equipment will only increase, positioning regenerative blowers as a crucial component in the future of industrial machinery.

As technology progresses, regenerative blowers are also expected to evolve. Innovations in materials and design will likely enhance their performance and durability. For instance, the integration of advanced composite materials could reduce weight while improving corrosion resistance, thus expanding their applicability in challenging environments.

Additionally, the growing concern for sustainability will drive manufacturers to focus on energy-efficient designs that minimize environmental impact. The implementation of smart technologies, such as IoT connectivity, may enable real-time monitoring and predictive maintenance, further enhancing operational efficiency and reducing downtime.

Moreover, as industries embrace automation and digital transformation, regenerative blowers will play a significant role in supporting these advancements. Their adaptability and reliability will contribute to seamless integration within automated systems, facilitating improved production processes and operational workflows.

To illustrate the practical benefits of regenerative blowers, let us explore a few case studies that highlight their effectiveness in various industries:

A municipal wastewater treatment plant faced challenges with its existing aeration system, which was inefficient and costly to operate. After evaluating different options, the facility opted to replace its aging blowers with regenerative blowers. The new system provided significant energy savings, reducing operational costs by approximately 30%. Moreover, the improved aeration efficiency enhanced the breakdown of organic matter, leading to higher water quality and compliance with environmental regulations.

A food packaging company sought to enhance its vacuum packaging process to extend product shelf life. By integrating regenerative blowers into their packaging lines, they achieved a more consistent and reliable vacuum, resulting in improved product preservation. The blowers' low noise levels also contributed to a more pleasant working environment, leading to increased employee satisfaction and productivity.

A high-speed printing company struggled with ink drying times, affecting production schedules. After implementing regenerative blowers into their drying systems, they experienced a marked improvement in drying times, allowing for faster turnaround on print jobs. This upgrade not only improved efficiency but also reduced energy consumption, aligning with the company’s sustainability goals.

To ensure the longevity and optimal performance of regenerative blowers, adhering to maintenance best practices is crucial. Here are some recommended practices:

By following these maintenance best practices, operators can extend the lifespan of regenerative blowers, ensuring they continue to deliver reliable performance in demanding industrial applications.

In conclusion, regenerative blowers are an integral part of modern industrial operations, offering a unique combination of efficiency, versatility, and reliability. Their design allows for effective pressure and vacuum generation, making them suitable for a wide array of applications across various sectors. As industries continue to innovate and prioritize energy efficiency, regenerative blowers will remain a vital solution for meeting these demands. By understanding their functionality, benefits, and best practices for maintenance, companies can leverage regenerative blowers to enhance their operational performance and achieve sustainable growth.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!