Regenerative blowers are versatile devices crucial in various industries for moving air and gases. Known for their efficiency and reliability, these blowers operate without contacting parts, ensuring low maintenance. This article delves into their functionality, applications, and what to consider when selecting a regenerative blower for your needs.

Regenerative blowers are integral components in many industrial applications, offering a reliable solution for moving air and gases. They are renowned for their ability to operate without contacting parts, minimizing wear and tear, and ensuring longevity. This article explores the inner workings of regenerative blowers, their diverse applications, and key considerations for choosing the right unit for specific needs. Additionally, we will delve deeper into the technology behind these blowers, their advantages over other types, and future trends in the industry.

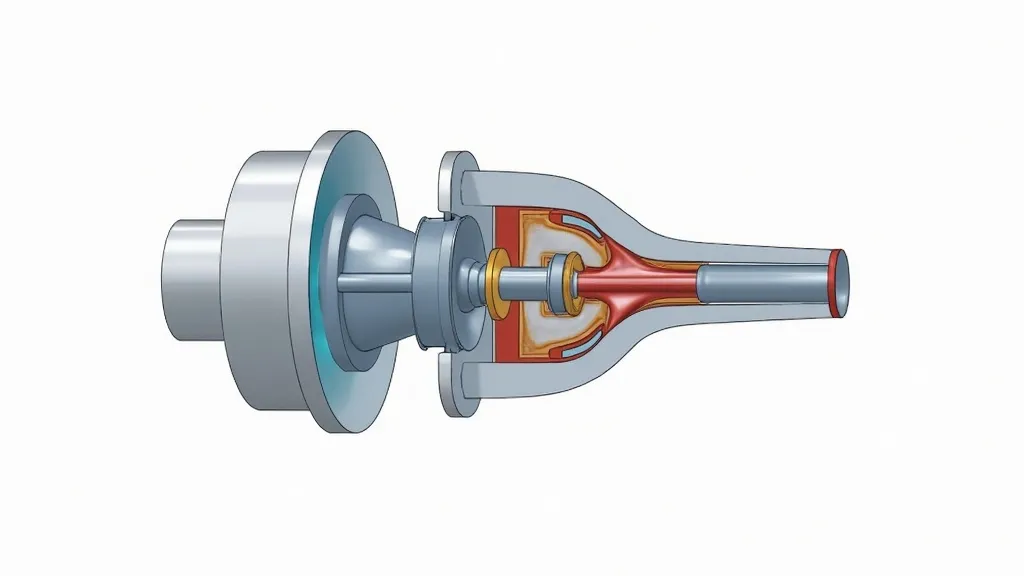

At the heart of a regenerative blower is an impeller, which spins within a housing. As the impeller rotates, air is drawn in through the inlet and accelerated outward by centrifugal force. This motion creates a vortex as the air moves around the blower's circumference, generating pressure and flow. The regenerative action occurs as the air is repeatedly circulated within the blower, intensifying the pressure without the need for internal compression.

The design of the impeller is critical to the performance of a regenerative blower. Typically made from high-strength materials, the impeller features multiple blades that are precisely angled to maximize airflow and pressure generation. As the impeller spins, the blades slice through the air, creating low-pressure zones that draw in additional air. This continuous cycle of drawing in and expelling air enhances efficiency and contributes to the blower's ability to maintain a steady flow rate.

Moreover, the housing surrounding the impeller is designed to minimize turbulence and maximize airflow efficiency. By carefully shaping the inlet and outlet ports, manufacturers can optimize the path that air takes through the blower, further enhancing its performance. This thoughtful engineering results in a device that can generate high pressure and flow rates while operating quietly and efficiently.

Regenerative blowers are versatile, finding applications across various sectors. In wastewater treatment, they provide the necessary aeration to support biological processes. Aeration is crucial as it helps to maintain the health of microorganisms that break down organic waste. Without sufficient oxygen, these microorganisms cannot function efficiently, leading to poor treatment outcomes. Regenerative blowers ensure a steady supply of air, promoting effective biological treatment and enhancing the overall performance of the treatment plant.

In manufacturing, they are used for vacuum hold-down and material handling. For instance, in woodworking and plastic manufacturing, regenerative blowers create a vacuum that holds materials in place during machining processes, ensuring precision and reducing waste. Their ability to handle large volumes of air at relatively low pressures makes them ideal for these applications.

These blowers are also prevalent in the packaging industry, where they assist in vacuum packing and pneumatic conveying. In vacuum packaging, they remove air from the packaging to extend shelf life by reducing oxidation and spoilage. Pneumatic conveying systems utilize regenerative blowers to transport materials through pipes, making it easier to move bulk materials from one location to another within a facility.

Other notable applications include aquaculture, where they are used to oxygenate water in fish farms, and in the electronics industry, where they help cool components in manufacturing processes. Their ability to operate in harsh environments and with minimal maintenance makes them a go-to solution in these diverse sectors.

When selecting a regenerative blower, several factors should be considered. The required pressure and flow rate are critical, as they determine the blower's size and power. An undersized blower may struggle to meet operational demands, leading to inefficiencies and potential system failures. Conversely, an oversized unit can result in unnecessary energy costs and increased wear.

Noise levels and energy efficiency are also vital, particularly in environments where these factors impact operations or costs. Many industries are now placing a premium on energy-efficient equipment, as this not only reduces operational costs but also aligns with sustainability goals. Look for blowers with high efficiency ratings and low decibel levels to ensure a conducive working environment.

Additionally, the material compatibility with the gases being moved must be assessed to ensure longevity and safety. For example, if the blower will be handling corrosive gases, it is essential to choose one made from materials that can withstand such environments. This consideration is crucial not only for the blower’s lifespan but also for maintaining safety standards within the facility.

Lastly, consider the operational environment. Factors such as temperature, humidity, and potential exposure to dust or contaminants can influence the performance and lifespan of a blower. Selecting a blower that is specifically designed for your operating conditions will result in better performance and reliability.

| Factor | Consideration |

|---|---|

| Pressure | Ensure the blower can achieve the necessary pressure for your application. |

| Flow Rate | Match the blower's capacity to the volume of air or gas needed. |

| Noise Level | Select a blower with an acceptable noise output for your working environment. |

| Energy Efficiency | Consider blowers with high efficiency to reduce operational costs. |

| Material Compatibility | Choose materials that resist corrosion and wear from the gases handled. |

| Size and Weight | Consider the physical dimensions and weight, ensuring it fits within your installation space. |

| Power Supply | Ensure compatibility with available power sources (single-phase or three-phase). |

| Maintenance Requirements | Evaluate the maintenance schedule and ease of access to components for servicing. |

Regenerative blowers offer several advantages over traditional blower types. One of the most significant benefits is their maintenance-free operation. Because the design minimizes contact between moving parts, there is less wear and tear, leading to reduced maintenance needs and costs. Users can expect longer service intervals and, ultimately, a lower total cost of ownership.

Another advantage is their compact design. Regenerative blowers tend to be smaller and lighter than other types of blowers, making them easier to install in tight spaces. This is particularly beneficial in industries where space is at a premium, allowing for more flexible layout designs.

In addition, regenerative blowers operate quietly, which is a critical consideration in many applications. Their low noise levels make them suitable for use in environments where noise pollution could be a concern, such as in residential areas or near workplaces where employees are sensitive to loud machinery.

Moreover, regenerative blowers are capable of handling both positive pressure and vacuum applications, making them versatile tools in various industrial settings. This dual capability reduces the need for multiple types of equipment, streamlining operations and minimizing capital expenditures.

Lastly, regenerative blowers are known for their energy efficiency. With advancements in technology, many of these blowers are designed to consume less power while delivering optimal performance. This not only benefits the environment but also helps companies reduce their energy bills significantly.

While regenerative blowers come with numerous advantages, they also have some challenges and limitations that users should be aware of. One significant limitation is their pressure capability. Although regenerative blowers can generate sufficient pressure for many applications, they may not be suitable for high-pressure requirements. In cases where extremely high pressure is needed, users may need to consider alternative blower types, such as positive displacement blowers or centrifugal blowers.

Additionally, regenerative blowers can be sensitive to changes in temperature and humidity. In environments with extreme conditions, performance can be affected. It is essential to account for these environmental factors when selecting a blower and ensure that it is rated for the intended operating conditions.

Another consideration is the air quality. Regenerative blowers are not the best choice for applications involving dust-laden or abrasive materials, as these can cause premature wear on the impeller and housing. In such cases, users should explore options with filtration systems or consider blowers designed specifically for handling such materials.

Finally, while regenerative blowers are energy-efficient, their efficiency can vary depending on operating conditions. Users must ensure that the blower is running within its optimal parameters to achieve the best efficiency rates. Regular monitoring and adjustments may be necessary to maintain performance levels.

Q: How do regenerative blowers differ from other types of blowers?

A: Unlike positive displacement blowers, regenerative blowers do not compress air in confined spaces. Instead, they move air in a regenerative manner, leading to lower maintenance costs and longer service life. In contrast, positive displacement blowers create pressure by trapping a fixed volume of air and forcing it into a smaller space.

Q: What maintenance is required for regenerative blowers?

A: Regular inspection and cleaning of the blower and its components are recommended to ensure optimal performance. However, due to their non-contact design, regenerative blowers require minimal maintenance compared to other types. Maintenance tasks may include checking for any blockages, ensuring proper lubrication of moving parts, and inspecting for signs of wear.

Q: Can regenerative blowers handle explosive gases?

A: While some regenerative blowers are designed to handle specific gases, it is crucial to check the manufacturer’s specifications for compatibility with explosive or hazardous gases. It is essential to use blowers that are certified for handling such materials to ensure safety and compliance with regulations.

Q: What industries commonly utilize regenerative blowers?

A: Regenerative blowers are widely used across various industries, including wastewater treatment, manufacturing, packaging, aquaculture, and electronics. Their versatility and efficiency make them suitable for numerous applications within these sectors, contributing to improved operational performance.

Q: How can I improve the energy efficiency of my regenerative blower?

A: To enhance energy efficiency, ensure that the blower is properly sized for your application, as an oversized unit will waste power. Regular maintenance, including cleaning inlet and outlet ports, can also improve efficiency. Additionally, consider incorporating variable frequency drives (VFDs) to optimize blower speed according to demand.

Regenerative blowers serve a critical role in various industrial processes with their efficient and maintenance-affordable operation. By understanding how these blowers function and what factors to consider when selecting one, businesses can optimize their operations and ensure a reliable and cost-effective solution for their air and gas handling needs. As technology advances, regenerative blowers are likely to continue evolving, with improvements in efficiency, performance, and environmental impact, making them an even more attractive choice for industries worldwide.

Furthermore, as industries increasingly focus on sustainability and energy efficiency, regenerative blowers are well-positioned to meet these demands. Their lower energy consumption and reduced maintenance needs align with the growing push for eco-friendly practices. Companies that adopt regenerative blowers can not only improve their operational efficiency but also contribute to a greener future.

In summary, whether you are involved in wastewater treatment, manufacturing, or packaging, understanding the capabilities and considerations surrounding regenerative blowers will empower you to make informed decisions that enhance productivity and reduce operational costs. The future of regenerative blowers looks promising, with continued advancements paving the way for even more innovative solutions in air and gas handling.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!