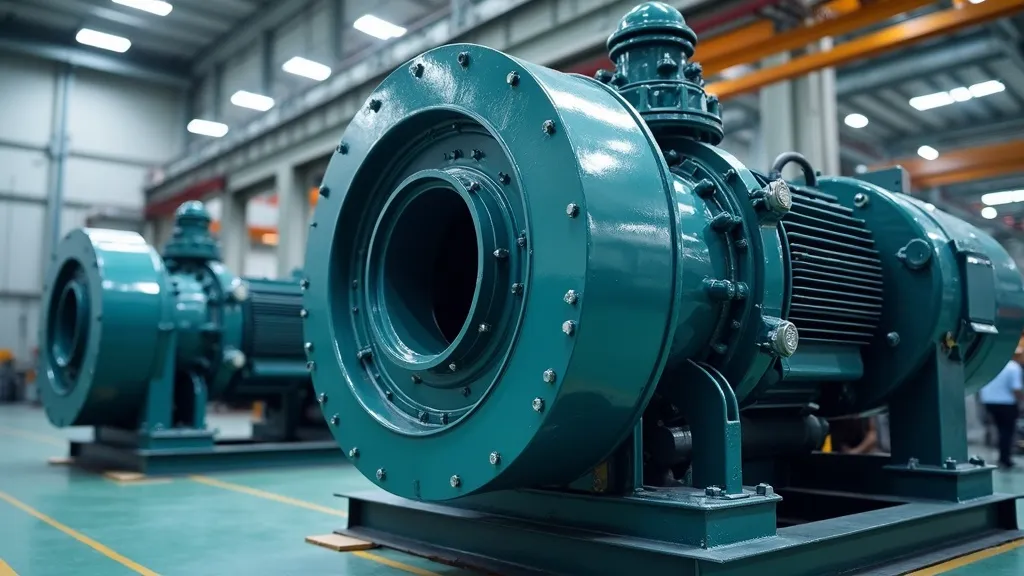

A regenerative blower is a type of air-moving device that offers high-pressure capabilities with a compact design, making it crucial in various industrial applications. Its functionality is distinct from traditional blowers or fans, as it circulates air or gas through a non-positive displacement method. This article delves into the mechanics, applications, and advantages of regenerative blowers, providing a comprehensive guide for industry professionals.

Regenerative blowers, also known as side channel blowers or ring compressors, are often pivotal in industrial operations requiring efficient air movement. Unlike traditional fans or blower systems, regenerative blowers utilize a unique design that allows them to generate higher pressures at lower flow rates. This capability makes them suitable for a wide range of applications, including wastewater treatment, pneumatic conveying, and vacuum systems. In addition to their technical advantages, regenerative blowers are also celebrated for their reliability and adaptability in various environments, making them a preferred choice for many industries.

The operation of a regenerative blower is based on the principle of non-positive displacement. The impeller, which is the central component, rotates within the casing to move air or gas. As the impeller spins, it draws air into the blower and accelerates it outward, creating a vortex. The air is then recirculated within the blower, passing through the impeller vanes multiple times, which increases the pressure before it exits the system. This method of air movement is highly efficient and results in continuous flow and pressure. The design allows for minimal turbulence, which is crucial for applications that require consistent air quality and flow.

Furthermore, regenerative blowers are designed to handle a variety of gases, not just air, allowing them to be used in specialized applications such as handling volatile organic compounds (VOCs) in the chemical industry. The ability to adapt to different gases without significant modifications makes regenerative blowers a versatile tool in numerous processes.

Regenerative blowers are versatile and can be found in numerous applications. In the wastewater treatment sector, they are used for aeration processes, providing the necessary oxygen to support bacterial growth for the breakdown of organic matter. The blowers ensure that the oxygen is evenly distributed throughout the treatment process, thereby enhancing the efficiency of the biological treatment stages.

In pneumatic conveying systems, they transport materials through pipelines by creating a vacuum or pressure difference. This application is especially beneficial in industries where bulk materials such as grains, powders, or pellets need to be moved swiftly and efficiently. The gentle nature of the airflow produced by regenerative blowers minimizes the risk of damaging fragile materials during transport.

Additionally, regenerative blowers are employed in medical devices, printing machines, and even in the aquaculture industry to maintain oxygen levels in water bodies. In medical applications, they can be used to power ventilators or in other respiratory devices where a steady flow of air or gas is paramount.

In the electronics manufacturing sector, regenerative blowers are utilized for cooling components during the production process, ensuring that sensitive electronic parts do not overheat. Their ability to deliver a consistent flow of air helps maintain optimal operating conditions, which is critical for quality assurance in high-tech manufacturing environments.

There are several advantages to using regenerative blowers in industrial settings:

| Feature | Regenerative Blower | Traditional Blower |

|---|---|---|

| Pressure | High | Low to Moderate |

| Flow Rate | Low | Varies |

| Noise Level | Low | High |

| Maintenance | Low | Moderate to High |

| Energy Efficiency | High | Variable |

| Application Versatility | High | Moderate |

Q: What industries benefit the very from regenerative blowers?

A: Industries such as wastewater treatment, aquaculture, and pneumatic conveying benefit significantly from regenerative blowers due to their efficiency and versatility. Beyond these, they are also valuable in food processing, pharmaceutical manufacturing, and chemical processing industries, where precise air handling is critical.

Q: How do regenerative blowers compare in terms of energy consumption?

A: Regenerative blowers are generally more energy-efficient than traditional blowers, as they are designed to maximize performance with minimal power usage. This energy efficiency not only reduces operational costs but also minimizes the environmental impact associated with energy consumption.

Q: Are regenerative blowers suitable for high-pressure applications?

A: Yes, they are particularly effective for high-pressure applications due to their ability to recirculate air and increase pressure efficiently. This characteristic makes them ideal for tasks such as pneumatic conveying in high-altitude environments or applications where high vacuum levels are necessary.

Q: What factors should be considered when selecting a regenerative blower?

A: Several factors should be considered, including the required flow rate, pressure, application type, and the environment in which the blower will operate. Additionally, it is essential to evaluate noise levels, energy consumption, and maintenance needs to ensure that the selected blower meets operational requirements effectively.

In conclusion, regenerative blowers are a crucial component in many industrial processes, offering advantages like compact design and energy efficiency. Their unique operational principles allow them to excel in various applications where traditional blowers may fall short. Understanding their operation and benefits can aid in making informed decisions for specific applications. As industries continue to evolve, regenerative blowers will likely remain an integral part of efficient and sustainable operations. With ongoing advancements in technology, the future of regenerative blowers looks promising, and their role in enhancing industrial processes will only expand as new applications are discovered.

As the demand for more efficient and environmentally friendly industrial solutions increases, regenerative blowers are poised to undergo significant technological advancements. Innovations in materials and design are expected to enhance their performance, reliability, and efficiency. For instance, the use of advanced composite materials could reduce the weight of blowers while improving their structural integrity and resistance to wear.

Moreover, the integration of smart technologies and automation will likely impact the regenerative blower market. Smart blowers equipped with sensors and IoT capabilities can provide real-time data on performance metrics, allowing for predictive maintenance and optimization of operational processes. This integration can lead to substantial cost savings and improved system reliability by preventing unexpected failures.

Another trend is the increasing focus on energy recovery systems that can capture and reuse energy within the blower system itself. This innovation could further enhance the energy efficiency of regenerative blowers, making them even more attractive for industries looking to reduce their carbon footprint.

To illustrate the effectiveness of regenerative blowers, we can examine specific case studies across various industries. In the wastewater treatment sector, a large municipal facility upgraded its aeration system by replacing traditional aerators with regenerative blowers. The result was a 30% reduction in energy consumption and improved oxygen transfer efficiency, leading to better treatment outcomes and lower operational costs.

In the food processing industry, a company that produces packaged snacks faced challenges related to maintaining consistent airflow and temperature control during production. By integrating regenerative blowers into their process, they achieved a more stable environment that enhanced product quality and reduced waste. The blowers provided precise airflow control, which was critical in preventing overheating and ensuring that the snacks were properly cooled before packaging.

In another example, a printing press manufacturer implemented regenerative blowers for drying applications. The blowers provided uniform airflow across the drying area, significantly reducing drying times and improving print quality. This enhancement allowed the manufacturer to increase production rates while maintaining high standards of quality control.

While regenerative blowers are known for their low maintenance requirements, implementing best practices can further enhance their reliability and longevity. Regular inspection of the blower’s components is crucial, including checking for signs of wear on the impeller and ensuring that the casing is free from obstructions.

Lubrication schedules should also be adhered to, as proper lubrication of bearings and other moving parts can prevent premature wear. Additionally, monitoring the blower's performance metrics, such as pressure and flow rates, can help identify potential issues before they escalate into more significant problems.

Cleaning the blower and its surrounding area is vital to prevent dust and debris from entering the system. Regularly replacing air filters, if applicable, will ensure that the blower operates efficiently and maintains the quality of the air being moved. Establishing a comprehensive maintenance plan tailored to the specific operational conditions can significantly extend the life of regenerative blowers and optimize their performance.

As industries strive for greater efficiency and sustainability, regenerative blowers will continue to play a crucial role. Their adaptability, energy efficiency, and low maintenance make them an attractive solution across a range of applications. With ongoing technological advancements and an increasing focus on environmental responsibility, regenerative blowers are well-positioned to meet the evolving needs of modern industries. By understanding their capabilities and implementing best practices for maintenance and operation, businesses can leverage the benefits of regenerative blowers to enhance productivity and reduce operational costs.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!