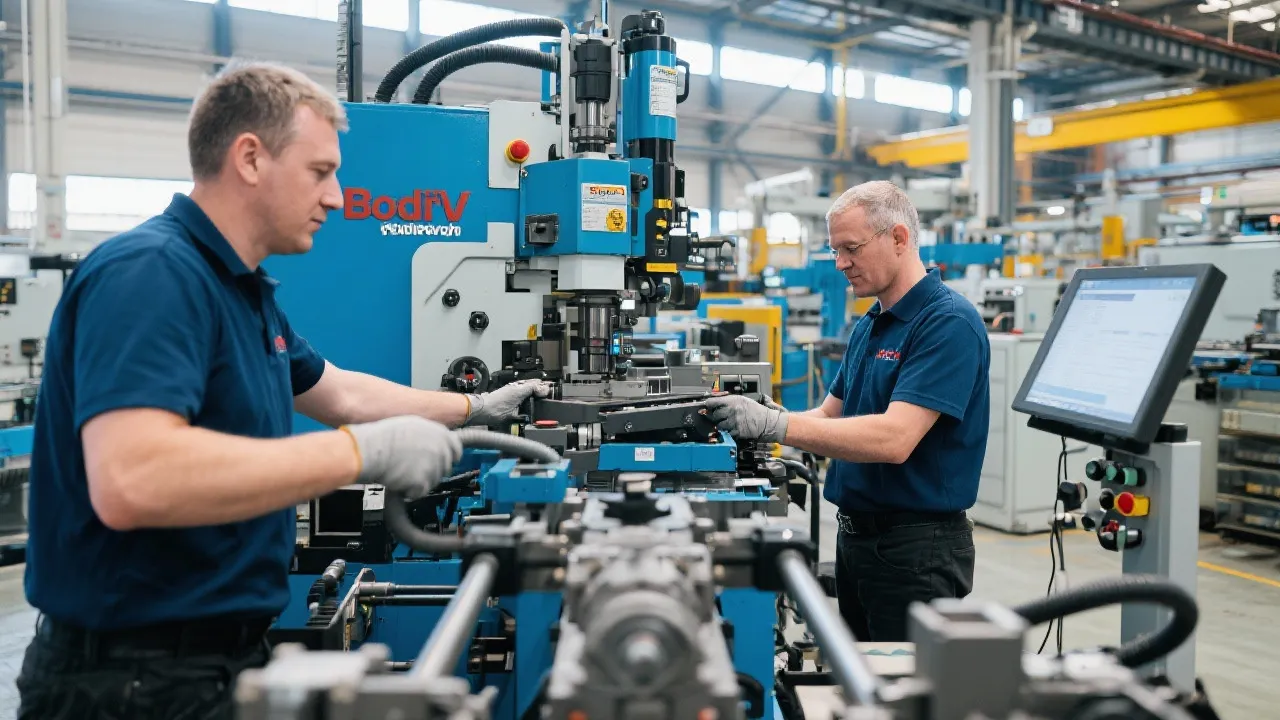

Bodiv Rexroth is a renowned name in the realm of industrial automation, offering reliable solutions for a variety of machinery and engineering applications. Known for technological innovation, Bodiv Rexroth components enhance efficiency and precision, making them ideal for engineering and industrial sectors globally. This article delves into the specifics of these components, examining their design, functionality, and applications in enhancing industrial productivity.

In the fast-paced world of industrial automation, precision and reliability are paramount. Among the leaders in this field, Bodiv Rexroth stands out for its innovative solutions and high-performance components. Known for their durability and advanced technology, Bodiv Rexroth components are integral to various industrial applications, enhancing machinery efficiency worldwide. The company’s journey began with a vision to revolutionize the industrial landscape, and it has indeed transformed the field of automation with its systematic approach to solving complex engineering challenges.

The contribution of Bodiv Rexroth to the automation industry cannot be overstated. Their components, ranging from hydraulic systems to electric drives and controls, are designed to optimize machinery performance and ensure seamless operation across different sectors. Trusted by engineers and manufacturers alike, Bodiv Rexroth systems are synonymous with precision engineering and groundbreaking technology. The company's commitment to enhancing operational productivity and efficiency has positioned them as a go-to solution for various industrial sectors.

Bodiv Rexroth not only develops its components to meet current demand but also anticipates future industrial requirements. This forward-thinking philosophy drives continuous improvements in their technology and systems. By collaborating with engineers and end-users, the company has developed solutions that not only resolve existing issues but also proactively address potential automation challenges. From designing user-friendly interfaces to incorporating advanced algorithms for predictive maintenance, Bodiv Rexroth is at the forefront of industrial innovation.

Here’s a closer look at some pivotal Bodiv Rexroth components that underscore their commitment to excellence:

Bodiv Rexroth employs a variety of cutting-edge technologies to enhance the effectiveness of their components. One such technology is the integration of IoT (Internet of Things) capabilities into their systems. This allows for real-time monitoring and data analytics, enabling companies to track the performance of their machinery and components. With IoT integration, operators can receive alerts about potential issues before they lead to failures, thus minimizing downtime and maintenance costs.

Moreover, machine learning algorithms are utilized to optimize performance continually. These algorithms analyze historical data to predict future operational behaviors, enabling companies to make informed adjustments that lead to greater efficiency and production rates. Such technologies are at the core of Bodiv Rexroth’s commitment to innovation and excellence, aligning perfectly with modern industrial demands for smart, connected systems.

Bodiv Rexroth components find utility in a multitude of sectors. From automotive manufacturing to food processing and beyond, these components play a crucial role in elevating production standards. Their adaptability and resilience make them a preferred choice for facilities aiming to enhance operational efficiency and reduce downtime. For instance, in automotive manufacturing, Bodiv Rexroth's hydraulic systems power robotics that assemble vehicles, while their electric drives ensure precision in the manufacturing process.

Food and beverage processing is another key area where Bodiv Rexroth's components shine. The sanitary design of their pneumatic systems makes them ideal for maintaining hygiene standards while ensuring efficient packing and bottling processes. Additionally, the pharmaceutical industry relies on Bodiv Rexroth components for critical applications that demand precision and reliability under stringent regulations.

In the logistics and warehousing sector, Bodiv Rexroth offers automated solutions that streamline material handling processes. Their advanced electric drive systems enable forklifts and conveyors to operate flawlessly, even under heavy loads, thereby improving overall warehouse productivity. Whether it's managing inventory or ensuring timely delivery of products, Bodiv Rexroth's innovations cater to the evolving needs of the industry.

Incorporating Bodiv Rexroth components into industrial systems offers numerous advantages:

| Benefit | Description |

|---|---|

| Improved Efficiency | By reducing operational disruptions and optimizing machinery functionality, Bodiv Rexroth components drive efficiency gains. Their systems are designed to minimize waste, cutting energy consumption and reducing operational costs. |

| Reliability | High-quality construction and design ensure lasting performance, reducing the need for frequent maintenance. This reliability translates into lower lifecycle costs, making Bodiv Rexroth components a wise investment for businesses. |

| Increased Precision | Enhanced control features contribute to greater accuracy in production processes. By utilizing advanced sensors and control algorithms, Bodiv Rexroth ensures that operations meet stringent quality standards. |

| Enhanced Safety | Safety protocols embedded within Bodiv Rexroth systems help prevent accidents, ensuring a safer workplace for operators. Their components often come equipped with fail-safe mechanisms and emergency stop features that enhance operational safety. |

| Scalability | Bodiv Rexroth's solutions are designed to grow with your business, providing the flexibility to expand or adapt systems without requiring extensive overhauls. This scalability is essential in today’s rapidly changing industrial landscape. |

When selecting Bodiv Rexroth components, consider the following factors:

As industries continue to evolve, the automation sector is witnessing groundbreaking trends, and Bodiv Rexroth is poised to lead in these transformations. One significant trend is the increase in automation of processes, powered by advancements in artificial intelligence (AI) and machine learning. These technologies allow for greater intelligence in machinery operation, enabling real-time decision-making that optimizes performance.

Bodiv Rexroth is actively engaged in developing AI-driven solutions that enhance automation capabilities, enabling manufacturers to achieve higher productivity levels while maintaining flexibility in their operations. The focus on creating smart factories, where machinery and systems communicate seamlessly, is where Bodiv Rexroth's expertise will play a crucial role.

Furthermore, sustainability is becoming an essential focus across industries. Companies are increasingly driven by the need to reduce their environmental impact. Bodiv Rexroth is responding to this demand by creating energy-efficient systems and components that minimize waste and reduce energy consumption. By incorporating sustainable practices and solutions into their product development, they are helping clients meet regulatory standards and corporate social responsibility goals.

Exploring real-world applications of Bodiv Rexroth components provides deeper insights into their impact on industries. Consider the automotive sector, where a leading manufacturer adopted Bodiv Rexroth hydraulic systems for their assembly line. The implementation led to a 30% increase in operational efficiency. The precision of their hydraulic systems enabled the manufacturer to reduce assembly time and enhance product quality, which translated into substantial cost savings and faster time-to-market.

In the food processing industry, a plant focused on improving its packaging line integrated Bodiv Rexroth pneumatic systems. By doing so, the plant achieved higher speeds and improved accuracy in packaging operations. The enhanced control over pressure and flow facilitated by Bodiv Rexroth's technology not only increased output but also ensured product quality was maintained throughout the process.

Another remarkable example comes from a logistics company that modernized their warehouse operations with Bodiv Rexroth electric drives. This upgrade allowed for better coordination between various material handling systems. With an increased system responsiveness and reliability, the company significantly decreased order fulfillment times and reduced operational costs through streamlined processes.

In the landscape of industrial automation, Bodiv Rexroth holds a significant position, thanks to its high-quality and innovative components. The extensive range of solutions provided by Bodiv Rexroth not only meets current industrial demands but also anticipates future technological needs. As industries continue to evolve, the demand for reliable and efficient automation solutions like those offered by Bodiv Rexroth is bound to grow. By investing in these components, companies can ensure superior performance, improve operational efficiency, and remain competitive in the global market.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!