Rexroth Cartridge Valves are essential components in hydraulic systems, known for their efficiency and reliability. Designed by Bosch Rexroth, a leader in drive and control technologies, these valves are pivotal in controlling hydraulic fluid flow to ensure optimal system performance. Their adaptability and durability make them a popular choice in various applications, from industrial machinery to mobile equipment.

In the realm of hydraulic systems, Rexroth Cartridge Valves stand out due to their robust design and unparalleled performance characteristics. Manufactured by Bosch Rexroth, a globally recognized leader in the field of drive and control technologies, these valves play a crucial role in the effective management of fluid flow within hydraulic circuits. Their inclusion in both industrial and mobile applications underscores their versatility and reliability. In recent years, the evolving demands of various industries have necessitated innovations in hydraulic control, making cartridge valves an increasingly popular solution for dynamic environments.

The mechanisms within hydraulic systems are complex, necessitating components that offer precise control, adaptability, and durability. Rexroth Cartridge Valves enable operators to achieve optimal performance and maintain fluid integrity. From a simple directional control to more complex functions involving flow regulation and pressure control, these valves are integral to the seamless functioning of hydraulic machinery. The fascination with cartridge valves lies in their ability to fuse advanced engineering with user-friendly features, making them an indispensable part of modern hydraulic systems.

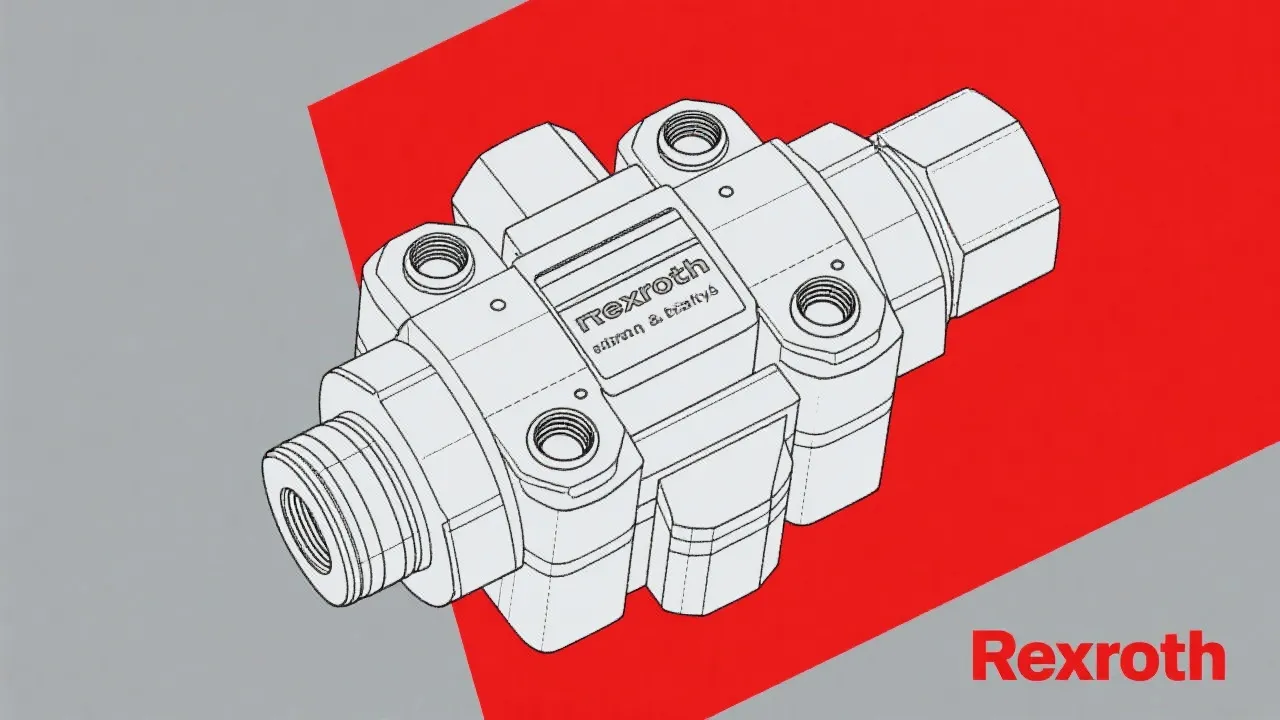

At the heart of Rexroth Cartridge Valves is their design, which prioritizes efficiency and ease of use. These valves are engineered to provide precise control over hydraulic fluid, which is critical for maintaining system stability and performance. Their compact form factor allows for integration into various system configurations without compromising on performance. Below are some of the standout features that contribute to the effectiveness of these valves:

In addition to these features, Rexroth Cartridge Valves also offer simplified installation processes. Their modular design not only cuts down on installation time but also allows for easier upgrades and maintenance. As technology advances, so too does the need for systems that can adapt without requiring complete overhauls, and Rexroth has made this a reality with their cartridge valve offerings.

Rexroth Cartridge Valves find application across a broad spectrum of industries, highlighting their adaptability and effectiveness. Some of the primary sectors utilizing Rexroth technology include:

These diverse applications demonstrate that Rexroth Cartridge Valves are not just pivotal components; they are integral to the advancement of technology in various industrial contexts, evolving alongside the needs of modern manufacturing and capital-intensive industries.

Maintaining Rexroth Cartridge Valves is crucial to ensuring their prolonged operational life and optimal performance. A well-informed approach to maintenance can preemptively address potential issues and provide a roadmap for upkeep. Here are some recommended practices:

| Aspect | Recommended Practice |

|---|---|

| Inspection Frequency | Bi-monthly visual checks |

| Replacement | Every 5 years or as needed based on condition and performance metrics |

| Fluid Quality | Test twice yearly or when performance issues arise |

In addition to these maintenance practices, it is paramount to involve trained personnel who can expertly handle hydraulic systems. Training is vital not only in recognizing mechanical issues but also in understanding the interconnected workings of hydraulic circuits involving cartridge valves.

As industries evolve, so does technology. Bosch Rexroth has consistently invested in research and development to enhance the performance of cartridge valves. Recent innovations include the integration of smart technology, enabling real-time monitoring and control of hydraulic systems. With Industry 4.0 gaining traction, smart Rexroth Cartridge Valves imbue hydraulic systems with enhanced intelligence.

Through the adoption of sensors and Internet of Things (IoT) technologies, these valves can now communicate operational data, allowing for predictive maintenance and analytics-based decision-making. Such innovations drive efficiency and reduce downtime, ensuring that operations not only run smoothly but also derive maximum productivity from the equipment involved.

Moreover, Rexroth is keen on sustainable practices. The development of environmentally friendly hydraulic fluids used in conjunction with their cartridge valves further promotes sustainability in industrial applications. Moving towards greener solutions is increasingly becoming a priority for many sectors, and Rexroth is well-aligned with this necessary trend.

Despite their advanced design, operations involving Rexroth Cartridge Valves can present challenges. A common issue faced by users is cavitation, which can damage valves and compromise system integrity. Cavitation occurs when there is a drop in pressure that causes the hydraulic fluid to vaporize. This phenomenon generates shock waves during the collapse of bubbles, leading to the physical erosion of the valve's internal surfaces.

To mitigate the risks of cavitation, operators must ensure that the hydraulic system is carefully designed and maintained. Maintaining appropriate fluid levels, ensuring correct pump sizing, and implementing temperature regulation can all help counteract cavitation. Moreover, regular training for personnel on identifying the signs of cavitation will further empower teams to address issues before they escalate.

Another challenge relates to valve responsiveness, especially in dynamic environments where quick adaptations are crucial. To address this, the use of proportional and servo valves in conjunction with Rexroth Cartridge Valves can facilitate improved responsiveness and precision in control. These technologies allow for fine-tuned adjustments to fluid flow, accelerating the system’s overall reaction times.

Q1: What makes Rexroth Cartridge Valves ideal for harsh environments?

A1: Their robust construction using high-quality materials makes them resistant to wear and corrosion, which is essential in harsh environments. This capability extends their functional life significantly, allowing operators to achieve high levels of performance consistency even under tough operating conditions.

Q2: Are Rexroth Cartridge Valves suitable for new installations and retrofitting existing systems?

A2: Yes, their compact design allows for easy integration into new setups and retrofitting into existing systems without major modifications. This adaptability is essential for companies looking to modernize without incurring exorbitant costs.

Q3: How can I determine when to replace my Rexroth Cartridge Valve?

A3: Regularly monitoring the valve’s performance characteristics, such as responsiveness and fluid control accuracy, can help determine if replacement is necessary. Additionally, following a predetermined inspection schedule will aid in identifying any degradation in valve performance, leading to informed maintenance decisions.

Q4: Can Rexroth Cartridge Valves help reduce energy consumption?

A4: Yes, the precise control offered by these valves allows for optimized fluid management, which translates to reduced energy usage. By minimizing waste and ensuring that hydraulic systems operate at their peak efficiency, operators can realize substantial decreases in energy costs over time.

Rexroth Cartridge Valves represent a vital component in hydraulic systems, providing dependable fluid control and enhancing operational efficiency. Their design reflects a commitment to quality and innovation, attributes that Bosch Rexroth is renowned for across various industries. The extensive adaptability and versatility of these valves testify to their importance in different operational contexts, enabling companies to achieve performance milestones while addressing modern operational challenges. For any business looking to enhance its hydraulic systems' performance, these valves are an investment in reliability and efficiency.

As the landscape of industrial applications continues to evolve, Rexroth Cartridge Valves will undoubtedly remain at the forefront of technological advancements, driving productivity and championing sustainable practices in hydraulic power control.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!