Rexroth Cartridge Valves play a crucial role in modern hydraulic systems by controlling flow, pressure, and directional movements efficiently. As components of modular hydraulic systems, these valves are renowned for reliability, durability, and precision. From industrial machinery to mobile systems, their adaptability and performance are pivotal to varied applications across industries.

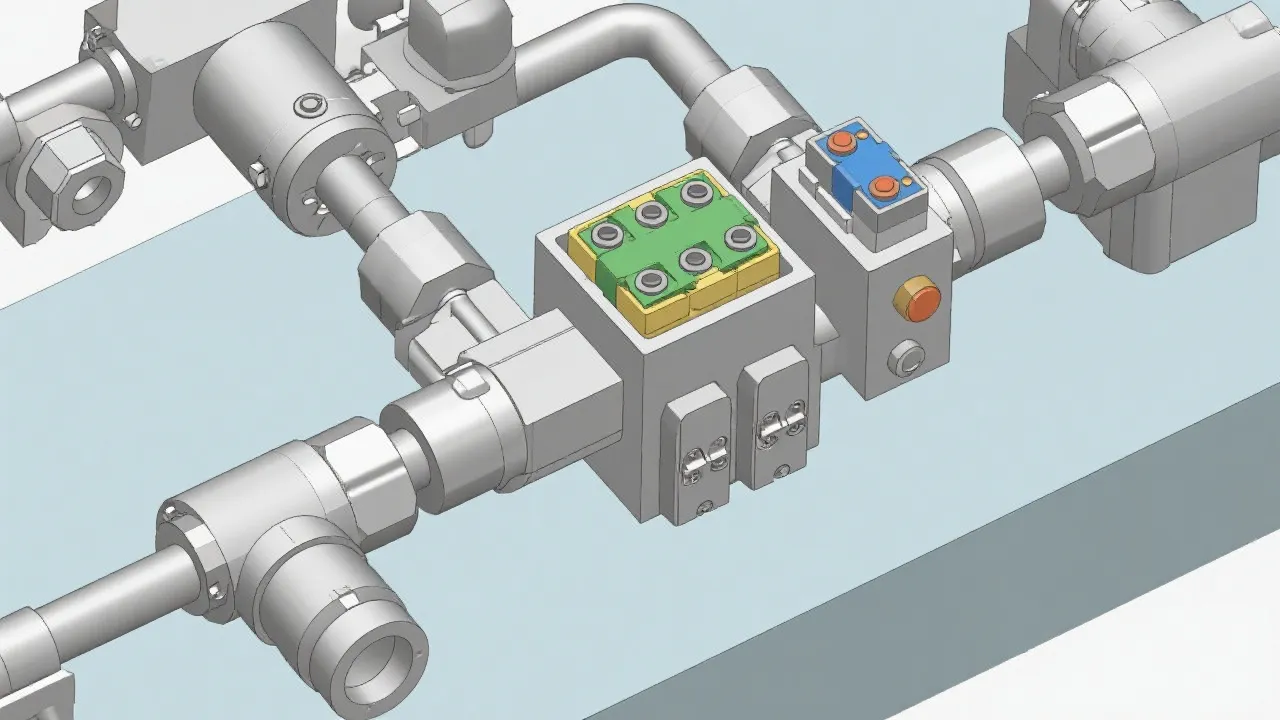

In the world of hydraulic systems, the name Rexroth stands out for its commitment to quality and innovation. Rexroth Cartridge Valves are integral parts used in controlling the flow, pressure, and direction of hydraulic fluid. Their modular design allows for customized solutions in both complex and straightforward hydraulic systems. This versatility makes them a common choice among engineers and manufacturers looking to optimize their hydraulic solutions.

Hydraulic systems rely heavily on precise control mechanisms to function effectively. Rexroth Cartridge Valves offer this precision through their variety and adaptability to serve different needs. They are used in applications ranging from industrial machinery to mobile equipment, ensuring smooth operations by modulating flow and pressure, ultimately enhancing the performance of the entire system. The successful implementation of these valves not only increases efficiency but also contributes greatly to the safety standards observed in hydraulic operations.

The primary function of these valves is to regulate hydraulic fluid within a system. Constructed with a cartridge design, these valves are renowned for their ability to be easily integrated or replaced within a manifold. This feature simplifies maintenance and reduces downtime. The valves are categorized based on their function:

Each category serves a specific role in managing hydraulic power, allowing for a system that is not only efficient but also highly responsive to operator commands.

These valves find utility in an array of sectors, showcasing their versatility and operational range:

What are the main types of Rexroth Cartridge Valves? Rexroth Cartridge Valves are primarily classified into pressure control, flow control, and directional control valves, each serving distinct roles in hydraulic systems. Understanding these categories helps in selecting the right valve for specific applications.

How do I choose the right cartridge valve for my system? Consider factors such as system pressure, flow rates, the type of control needed, and the specific application. It is often beneficial to consult with a hydraulic specialist or engineer to ensure optimal selection, as the improper valve choice can lead to system inefficiencies or failures.

What makes Rexroth Cartridge Valves stand out from competitors? The combination of reliability, durability, and precision engineering, along with a reputation for excellent customer support, distinguishes Rexroth from other brands. Their investment in research and development also enables them to stay ahead in technology and innovation, continually improving their product offerings.

Rexroth Cartridge Valves are a vital component in ensuring that hydraulic systems operate effectively and efficiently. Their design and construction make them essential in a range of industries, providing the precision and reliability needed in demanding applications. Understanding their functions and advantages allows businesses to maintain optimal performance and longevity in their hydraulic systems. By choosing Rexroth, companies benefit from decades of experience in hydraulic engineering, ensuring that their equipment meets the challenges of modern-day demands.

| Resource Type | Description |

|---|---|

| Technical Manuals | Detailed guides on operation, maintenance, and installation of cartridge valves. These manuals often include troubleshooting tips and common issues faced and best practices for resolutions. |

| Webinars | Online sessions hosted by hydraulic experts discussing top practices, innovations in cartridge valve technology, and real-world case studies showcasing the benefits of these valves in various applications. |

| Industry Reports | Analysis of trends and forecasts in the application of hydraulic systems globally. These reports often cover emerging technologies and consumer demands in hydraulic applications, aiding businesses in strategic planning. |

| Case Studies | Detailed examinations of specific installations and implementations of Rexroth Cartridge Valves, with insights into performance improvements and operational efficiencies gained through their application. |

| Technical Support | Access to expert technicians who can provide advice on system design and integration, helping customers troubleshoot any challenges with existing hydraulic systems. |

| Training Programs | Workshops and seminars aimed at educating engineering and maintenance personnel on best practices for installation, operation, and maintenance of hydraulic systems featuring Rexroth products. |

To fully appreciate the role of Rexroth Cartridge Valves, it's beneficial to understand the fundamentals of hydraulics. Hydraulic systems are primarily based on Pascal’s principle, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid. This property allows hydraulic machines to multiply force and facilitate operational efficiency in various applications.

Hydraulics harness the power of fluids to perform work, and this characteristic is evident in everyday machinery such as lifts, presses, and earth-moving equipment. By converting energy into mechanical work, hydraulics plays a critical role across different industries, making it a cornerstone technology in modern engineering.

As industries evolve, so too do the technologies used within those sectors. The future of hydraulic systems, including the use of Rexroth Cartridge Valves, seems poised for exciting advancements. With the growing emphasis on automation, energy efficiency, and sustainability, innovative approaches in hydraulic system design are emerging.

In particular, the integration of smart technology into hydraulic systems is making waves. Smart sensors and IoT (Internet of Things) capabilities are enabling more intricate monitoring and control of hydraulic parameters. These advancements promise to enhance the decision-making process in real time, leading to improvements in efficiency and the proactive prevention of mechanical failures.

Furthermore, the push for sustainability is leading to increased research into biodegradable hydraulic fluids and energy-reducing technologies. Rexroth is continually exploring these avenues to ensure their products not only meet current industry demands but also adhere to environmentally friendly practices.

As we look to the future, it’s clear that hydraulic systems will continue to evolve alongside technological advancements. Rexroth Cartridge Valves will play a pivotal role in this evolution, adapting to new trends while retaining their core advantages of reliability, precision, and modularity. By keeping abreast of these shifts, companies can ensure they are using the best technology available for their hydraulic systems, maximizing productivity and efficiency while addressing the growing demands for sustainability and smart technology integration. As the landscape of hydraulic systems continues to transform, embracing these changes will be crucial for businesses aiming to stay competitive and at the forefront of their industries.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!