Rexroth Cartridge Valves are integral components in hydraulic systems, providing precise control and high efficiency. These valves are designed for robustness and reliability, being adaptable to various industrial applications. They play a critical role in managing fluid flow, pressure, and direction, enhancing overall system performance.

Rexroth Cartridge Valves represent a significant advancement in fluid control technology, offering precision, durability, and versatile application capabilities within hydraulic systems. As a leading manufacturer in hydraulic equipment, Bosch Rexroth sets a standard in enhancing industrial productivity and efficiency through its innovative valve solutions. These cartridge valves are integral to ensuring optimal performance in industries ranging from manufacturing to heavy machinery. Specifically designed to meet the demands of modern hydraulic applications, Rexroth Cartridge Valves provide solutions that are not only effective but also adaptable to a variety of operational needs.

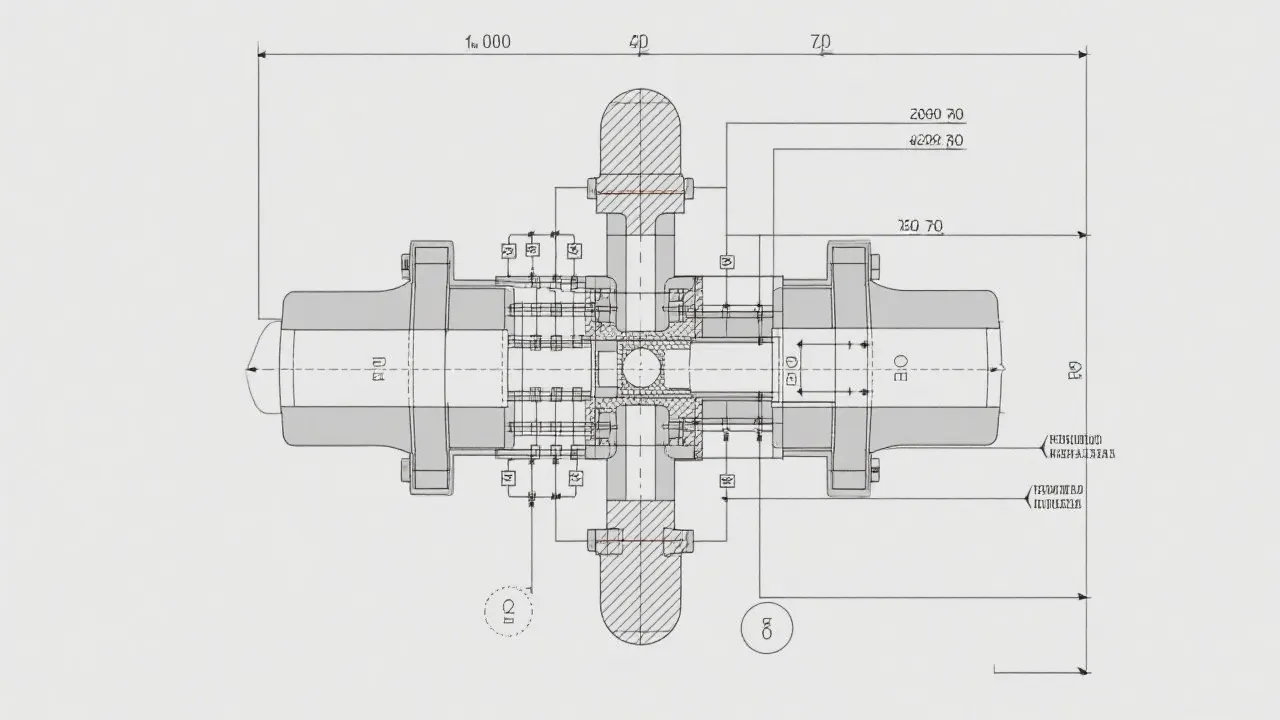

Cartridge valves are essential components within hydraulic circuits, designed to efficiently manage the flow and pressure of hydraulic fluid. Their modular design facilitates easy installation and maintenance, thereby minimizing downtime and ensuring consistent operational efficiency. Rexroth Cartridge Valves are particularly renowned for their durability and ability to perform in demanding environments. Cartridges are housed within a compact assembly, optimizing space in hydraulic systems, which is particularly beneficial in applications where space is a premium. Their ability to handle high flow rates and pressures makes them suitable for an extensive range of applications, enhancing performance and dependability.

Rexroth Cartridge Valves are distinguished by several key features, including:

The versatility of Rexroth Cartridge Valves makes them suitable for an array of applications. Industries such as automotive manufacturing, heavy equipment, and automated machinery rely on these valves for precise and reliable hydraulic control. They are vital in tasks that require accurate modulation of hydraulic systems, including load holding, regenerative circuits, and high-pressure safety systems. Furthermore, they find applications in mobile machinery, such as forklifts and cranes, where precise control of movements and loads is crucial.

In the agriculture sector, these valves are leveraged to enhance the functionality of precision farming equipment, enabling growers to utilize their machines with improved efficiency and effectiveness. Moreover, they are employed in marine applications where hydraulic control must often contend with harsh environmental conditions, showcasing the durability and reliability of Rexroth Cartridge Valves under challenging circumstances.

Other notable applications include construction equipment, conveyor systems, and plastic injection molding machinery, reflecting the valves' broad utility in enhancing operational efficiency and safety across diverse manufacturing processes.

When compared to traditional valve systems, Rexroth Cartridge Valves offer a host of benefits:

| Features | Traditional Systems | Rexroth Cartridge Valves |

|---|---|---|

| Installation | Complex and time-consuming due to multiple components and fittings. | Modular and straightforward, allowing for quick assembly and modifications. |

| Maintenance | Often requires specialized skill set and tools for repairs and replacements. | Designed for easy access and minimal downtime, simplifying routine maintenance tasks. |

| System Efficiency | Variable, often affected by the interplay of individual components. | High efficiency achieved through precision engineering and optimized fluid dynamics. |

| Sustainability | Use of less efficient materials and designs leading to increased operational waste. | Made with advanced materials and designs that promote energy efficiency and lower environmental impact. |

In assessing the performance of hydraulic systems, Rexroth Cartridge Valves stand out for their consistency and reliability. They are engineered to withstand high pressure and adverse conditions, thus ensuring steady system performance across various operational spectrums. This enhances system stability and optimizes energy usage, crucial for sustainable industrial processes. In practice, this might mean providing reliable power in a hydraulic press that requires unyielding pressure application or ensuring that a mobile hydraulic system can function without loss of control or failure under load.

The design of these valves significantly reduces the risk of fluid leakage, which not only improves safety but also decreases operational costs associated with fluid losses and contamination. Moreover, advanced sealing technologies used in Rexroth Cartridge Valves minimize internal leakage, which directly contributes to improved overall system efficiency. An efficient hydraulic system directly translates into lower energy consumption and decreased operating costs, making these valves a smart investment for industries focused on cost and operational excellence.

The technological advancements incorporated in Rexroth Cartridge Valves go beyond traditional hydraulic elements. Bosch Rexroth employs cutting-edge materials and manufacturing techniques that enhance the performance of their cartridge valves. For example, the use of composite materials for valve bodies can improve wear resistance and thermal stability compared to metal counterparts. This innovation leads to longer life cycles and reduces the frequency of replacements, which can be especially beneficial in demanding applications frequently exposed to intense conditions.

Additionally, Rexroth has integrated electronic control systems with their hydraulic valve technology, enabling dynamic control of the valves through sophisticated software algorithms. This integration allows for real-time monitoring and adjustment of fluid parameters, enhancing precision and responsiveness in hydraulic operations. Such smart systems can lead to notable improvements in energy efficiency, as they adapt the flow and pressure in accordance with the operational demands, thereby minimizing waste.

Rexroth Cartridge Valves symbolize the pinnacle of hydraulic valve technology, combining precision, adaptability, and efficiency. Their contribution to enhanced industrial performance is undeniable, underlining Bosch Rexroth's commitment to excellence in hydraulic solutions. As industries continue to evolve and demand more sophisticated systems, Rexroth Cartridge Valves remain at the forefront of innovation, ensuring robust and reliable industrial solutions.

In the rapidly changing landscape of industrial automation, maintaining operational efficiency while embracing sustainability has become paramount. With the integration of smart technologies and the use of advanced materials, Rexroth Cartridge Valves are positioned to meet these challenges head-on. Their unique advantages not only provide immediate benefits in terms of performance and reliability but also pave the way for a more sustainable future in hydraulic applications. As businesses strive to enhance productivity and reduce their environmental footprints, Rexroth Cartridge Valves will undoubtedly play an indispensable role in shaping the future of fluid control technology.

Overall, the impact of Rexroth Cartridge Valves is profound, setting trends that other manufacturers aspire to in the quest for better hydraulic solutions. Whether in high-performance automotive applications or rugged construction machinery, their reliability and efficiency ensure that systems operate at their best, bolstering production goals and reducing maintenance costs. As technology continues to advance, customers can anticipate further enhancements to the design and functionality of these essential components, affirming their status as a leading choice in fluid control solutions.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!