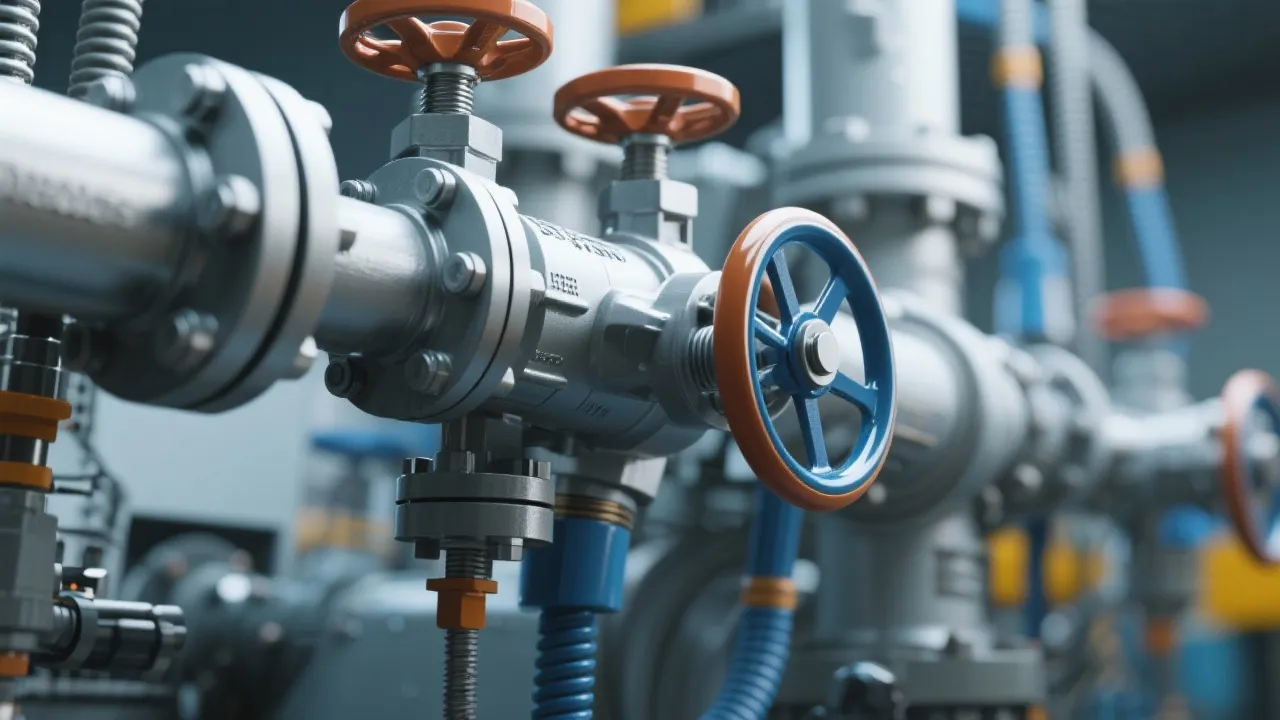

Explore the functionality and efficiency of Rexroth Cartridge Valves, key components in hydraulic systems known for their durability and performance. These valves play a crucial role in controlling fluid flow, pressure, and direction in various industrial applications. Understanding their types and applications provides insights into optimizing hydraulic systems for enhanced productivity and reliability.

Rexroth Cartridge Valves are integral components in hydraulic systems, renowned for their precision and reliability. These valves are engineered to control the flow, pressure, and direction of fluids within hydraulic circuits, making them indispensable across a multitude of industries. Known for their durability and efficiency, Rexroth Cartridge Valves are pivotal in enhancing the performance and longevity of hydraulic systems. Their compact design and versatility make them suitable for a range of applications, underscoring their vital role in modern hydraulic engineering. In this comprehensive guide, we will explore the various functionalities, types, applications, and considerations essential for selecting the right Rexroth Cartridge Valve for specific needs.

At the core, cartridge valves are designed to regulate the flow of hydraulic fluid within a system, ensuring that pressure is maintained and operations can proceed smoothly. These valves operate by moving internal components in response to pressure changes, allowing for the selective application of hydraulic power. The importance of these valves cannot be overstated, as they play a crucial role in preventing system overloads and ensuring precise operation.

Cartridge valves come in various configurations, including directional, pressure, and flow control types, each serving to optimize different aspects of hydraulic circuit performance. For instance, while directional control valves dictate the path of fluid flow, pressure control valves ensure that maximum system pressure limits are not exceeded. Flow control valves, on the other hand, adjust the velocity of fluid to meet operational requirements, making them vital for applications that necessitate variable speed operations.

In addition, cartridge valves are frequently integrated into manifold systems, which allows for multiple valves to function in conjunction, significantly reducing the amount of space needed in hydraulic systems. This design consideration not only saves space but also increases the efficiency of the hydraulic setup, making it easier to manage and service.

Rexroth Cartridge Valves find their application in a multitude of industries due to their robust design and exceptional performance. Common sectors utilizing these valves include manufacturing, aerospace, construction, and marine industries. The versatility of cartridge valves allows them to be employed in various machinery such as forklifts, cranes, presses, and hydraulic jacks. Their ability to function seamlessly in critical applications, such as aircraft hydraulic systems or offshore drilling platforms, highlights their importance in modern industrial processes.

In the manufacturing sector, Rexroth Cartridge Valves are often utilized in automated machinery, where precision control of motion and flow is essential. In the aerospace industry, these valves play a critical role in hydraulic systems for aircraft, ensuring safe and reliable operation under varying loads and conditions.

The construction industry benefits from using cartridge valves in heavy equipment such as excavators and bulldozers, where robust hydraulic systems are essential for performance and efficiency. Marine applications further illustrate the adaptability of these valves, as they are used in winches, steering systems, and lifting devices, where reliability and safety are paramount.

Choosing the correct Rexroth Cartridge Valve involves careful consideration of several factors, including the specific requirements of the hydraulic system, the flow capacity, pressure rating, and the environmental conditions of operation. The compatibility of the valve with the application is critical, as mismatched components can lead to inefficiencies or failures.

When selecting a valve, it is important to assess the following criteria:

Experts recommend consulting with hydraulic engineers to match system needs with valve specifications for optimal performance. Additionally, understanding the unique characteristics of each valve type can help operators make informed decisions that enhance efficiency and safety.

| Valve Type | Function | Suitable Industries | Common Applications |

|---|---|---|---|

| Directional Control | Ensures flow direction | Manufacturing, Automotive | Cylinder actuation, Robotic arms |

| Pressure Control | Manages system pressure | Aerospace, Marine | Engine systems, Deck machinery |

| Flow Control | Regulates flow rate | Construction, Energy | Hydraulic lifts, Injection molding |

| Check Valves | Prevents backflow | Mining, Industrial | Hydraulic circuits, Pump systems |

| Relief Valves | Prevents excessive pressure | Oil & Gas, General Manufacturing | Pressure relief systems, Safety applications |

To ensure the longevity and optimal functioning of Rexroth Cartridge Valves, proper maintenance is crucial. Here are several maintenance tips that can help:

As industries continue to evolve, so does the technology behind hydraulic systems and associated components, including Rexroth Cartridge Valves. Some future trends to watch for in hydraulic technology include:

In conclusion, Rexroth Cartridge Valves are essential components that provide control and efficiency in hydraulic systems. Understanding their types and functionalities helps in selecting the right valve that meets specific industrial needs, thereby optimizing system performance and ensuring safety. As industries continue to evolve, the role of these valves will remain integral in facilitating advancements and sustaining operational excellence. By investing in high-quality cartridge valves and prioritizing proper maintenance, organizations can enhance productivity, reduce operational costs, and achieve long-term success in their hydraulic applications.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!