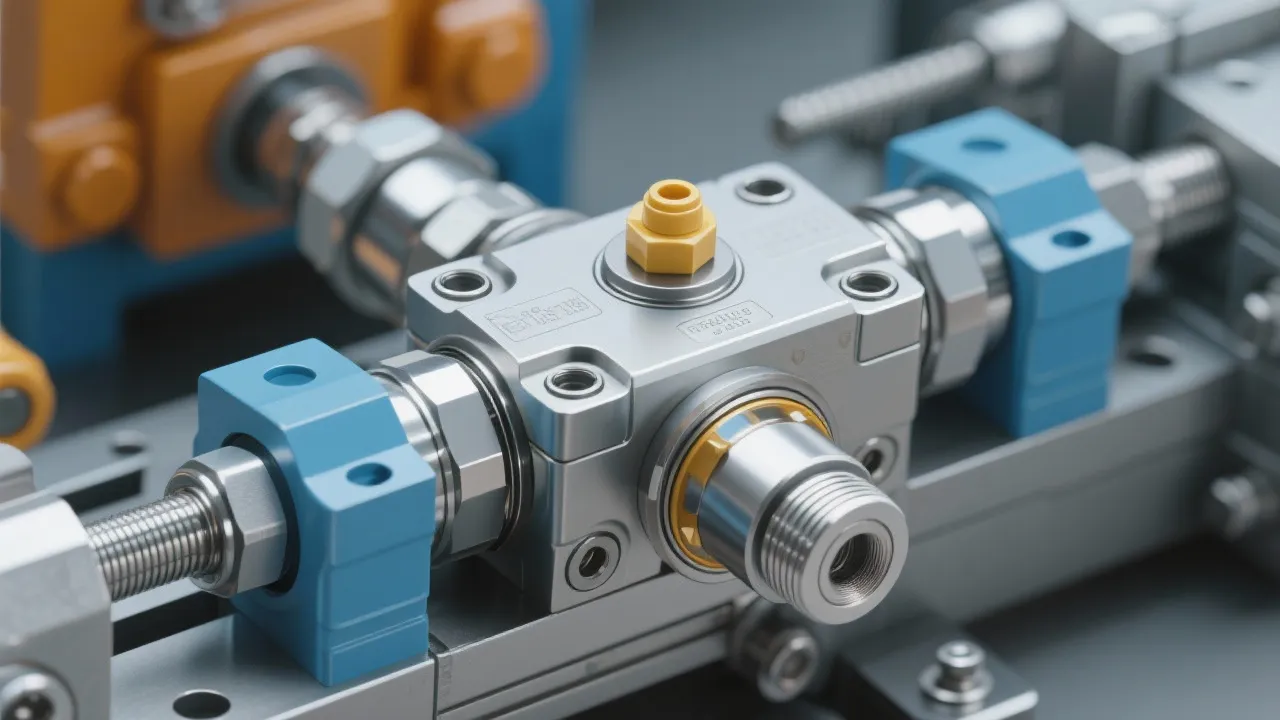

This article explores the complexities and functionalities of Rexroth Cartridge Valves, essential components in modern hydraulic systems known for enhancing efficiency and precision. Originating from Bosch Rexroth's pioneering technology, these valves play a critical role in various industries by controlling fluid flow in hydraulic systems to meet demanding operational requirements.

Rexroth Cartridge Valves are sophisticated components used in hydraulic systems to manage pressure, control flow, and direct fluid movement efficiently. These valves are vital in applications where precision and reliability are crucial, such as in manufacturing, automotive, and heavy machinery industries. Bosch Rexroth, a leader in drive and control technologies, produces these valves, ensuring they meet global standards for quality and performance. The innovation surrounding Rexroth Cartridge Valves represents a significant advancement in hydraulic technology, providing solutions that enhance operational efficiency.

In the realm of hydraulic systems, selecting the appropriate components can significantly impact performance and productivity. Rexroth Cartridge Valves stand out due to their ability to control hydraulic systems in real-time, adapting to varying demands while maintaining performance integrity. The integration of these valves in hydraulic systems not only improves flow characteristics but also assures system stability. This makes them a preferred choice for engineers and designers aiming for high-performing hydraulic solutions.

Rexroth Cartridge Valves are renowned for their compact design, ease of integration, and high-efficiency output. These valves offer superior flexibility in system design due to their modular nature, allowing engineers to tailor hydraulic systems to specific needs. The features of these valves include:

In industrial settings, Rexroth Cartridge Valves are used to control and throttle flow in advanced hydraulic circuits. Their application spans across sectors such as:

When selecting Rexroth Cartridge Valves for your system, several criteria should be evaluated to ensure compatibility and performance:

| Criteria | Considerations |

|---|---|

| System Pressure | Ensure the valve can withstand the maximum pressure of your hydraulic system. Choosing valves rated above your maximum system pressure ensures reliability and safety. |

| Flow Rate | Select a valve that meets the required flow rate for efficiency without causing unnecessary pressure drops. Accurate flow rate selection is essential for optimal hydraulic performance. |

| Fluid Type | Compatibility with the hydraulic fluid used is essential to maintain performance and lifespan. Different fluids can have varying properties, affecting the valve's performance if not adequately matched. |

| Environment | Consider the surrounding environment where the valve will operate. Factors such as temperature fluctuations, humidity, and exposure to contaminants can influence the choice of materials and sealing types. |

| Installation Space | Assess the available space for installation, as compact designs may be necessary in constrained environments, making Rexroth’s cartridge option favorable. |

Rexroth Cartridge Valves are integral to efficient and reliable hydraulic systems across a multitude of industrial applications. Their precision, durability, and flexibility make them invaluable in optimizing performance and ensuring seamless operations. By understanding their functions and selecting the right model for your needs, businesses can significantly enhance their system's effectiveness and longevity.

In conclusion, the advancements in hydraulic technology brought about by Rexroth Cartridge Valves have not only improved efficiency in industrial applications but have also paved the way for innovations in systems that demand high precision and reliability. Embracing these sophisticated solutions will enable industries to meet the ever-increasing challenges of today’s market while maintaining competitive edges in their respective fields. The importance of choosing the right components cannot be overstated, as the integration of quality valves directly influences the overall productivity and safety of hydraulic systems.

As the industry grows and evolves, the demand for better-performing hydraulic solutions will only increase. It is crucial for engineers and decision-makers to stay informed about the latest developments and advancements in technology surrounding hydraulic systems, particularly those related to Rexroth Cartridge Valves. With a commitment to continuous improvement and responsiveness to market needs, Bosch Rexroth is poised to remain at the forefront of hydraulic technology, offering solutions that cater to diverse industrial requirements.

The future of hydraulic systems is bright, driven by innovations in control technologies and sustainable practices. As industries increasingly focus on energy efficiency and reduced environmental impact, the capabilities of Rexroth Cartridge Valves will continue to play a pivotal role in shaping next-generation hydraulic systems that not only meet operational demands but also uphold environmental standards.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!