Rexroth Cartridge Valves play a crucial role in modern hydraulic systems, offering precise flow control and reliability. Known for their efficiency and robust design, these valves are a staple in industries seeking optimized performance. Explore their applications, features, and the benefits they bring to various sectors, highlighting why they remain a preferred choice in hydraulic solutions.

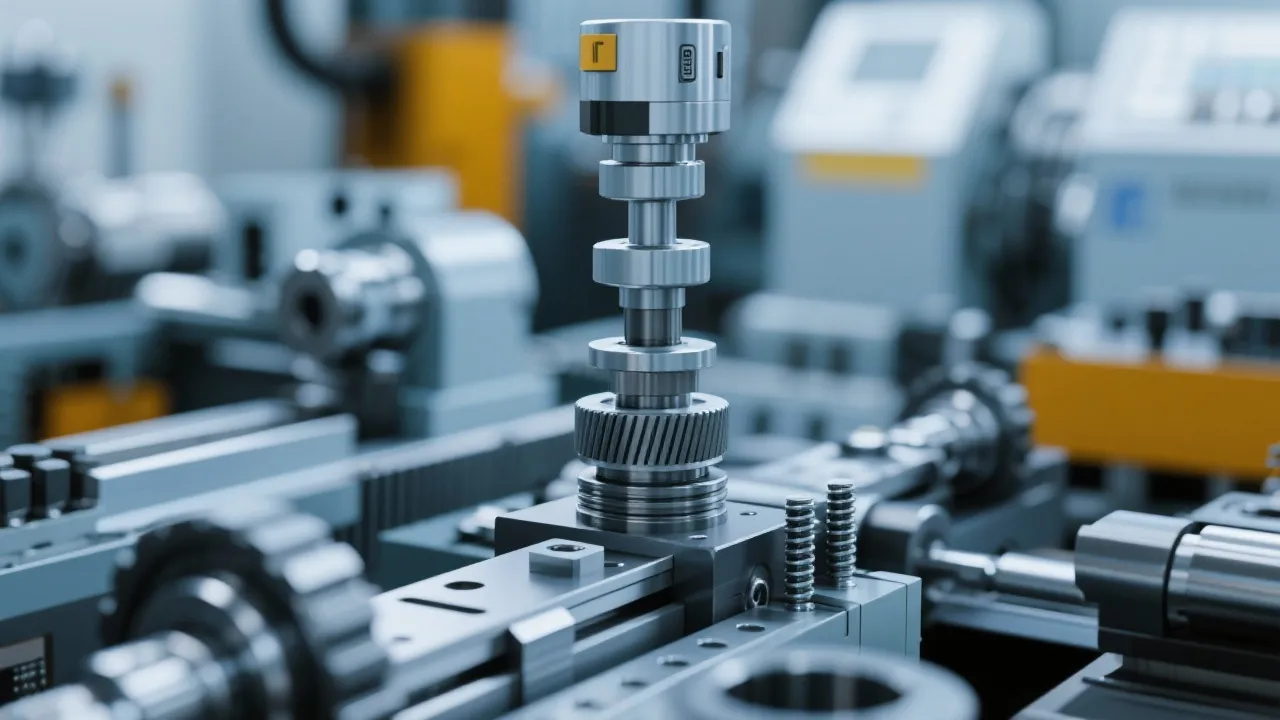

In the realm of hydraulic systems, precision and reliability are paramount. Rexroth Cartridge Valves are renowned for meeting these demands, becoming essential components in various industrial applications. Known for their robust design and efficiency, Rexroth Cartridge Valves ensure optimal performance and longevity in hydraulic systems. Their design minimizes leakage and enhances the overall reliability of the system.

The evolution of hydraulic technology has also influenced the design of these valves, leading to innovations that improve their functionality and response times. As industries grow increasingly automated, the demand for high-performance hydraulic components like Rexroth Cartridge Valves continues to escalate. This article delves into the critical features, benefits, specifications, applications, and the emerging trends in the use of Rexroth Cartridge Valves.

Rexroth Cartridge Valves are engineered to manage fluid flow precisely and reliably within a hydraulic circuit. These valves are distinguished by their compact size, allowing for easy integration into systems while maximizing space efficiency. Their design minimizes leakage and enhances the overall reliability of the system. This is particularly beneficial in applications where fluid integrity and system uptime are crucial.

Another hallmark of Rexroth Cartridge Valves is their versatility. They cater to a broad range of applications, from industrial machines to mobile equipment, providing solutions in sectors like construction, manufacturing, and agriculture. This versatility stems from their capability to handle varying pressures and flows, adapting to the specific needs of different applications. Furthermore, their modular design enables easy assembly and disassembly, facilitating quick repairs and maintenance.

The materials used in manufacturing Rexroth Cartridge Valves are also noteworthy. High-quality metals and advanced polymers are employed to withstand high temperatures and corrosive environments. This results in reduced wear over time, which contributes to the longevity of the valves and, by extension, the hydraulic systems they serve.

Rexroth Cartridge Valves come in various types, including directional, pressure, and flow control valves, each serving distinct functions within hydraulic systems. Directional control valves manage the path through which the fluid flows, pressure control valves maintain the desired pressure in the system, and flow control valves adjust the rate of flow, optimizing performance.

Each valve type is crafted with precision, utilizing high-quality materials to withstand harsh environments. This durability ensures that Rexroth Cartridge Valves provide a sustainable solution, reducing the need for frequent replacements and maintenance. The technological advancements in valve design mean that many Rexroth products now incorporate electronic controls, providing real-time monitoring and adjustments, which further optimize system performance.

The operational parameters for Rexroth Cartridge Valves are equally impressive. Many models are designed to handle pressures up to 420 bar (6,000 psi) and flows of up to 120 liters per minute, emphasizing their capability to perform in high-demand situations. These specifications make them suitable for both light-duty and heavy-duty applications, ensuring versatility and adaptability across various sectors.

Industries worldwide leverage Rexroth Cartridge Valves for their reliable performance in demanding settings. In construction, these valves are integral in the operation of excavators and cranes, where they ensure smooth and controlled movements. They play an essential role in allowing operators to manage multiple hydraulic functions simultaneously, contributing to enhanced safety and efficiency on job sites.

In manufacturing, they regulate fluid dynamics in automated processes, enhancing efficiency and productivity. For instance, conveyor systems often rely on hydraulics to automate the movement of products. Rexroth Cartridge Valves enable precise control over the speed and direction of actuation, which is crucial in maintaining the efficiency of the production line.

Agriculture also benefits significantly from these valves, as they enable precise operation of machinery that assists in planting, irrigation, and harvesting. The adaptability of Rexroth Cartridge Valves to various hydraulic systems is a testament to their engineering excellence. For example, in modern farming equipment, where every second counts, these valves support functions like seed planting depth control and real-time adjustments for soil moisture levels. This maximizes resource use and crop yields.

As industries evolve, so too do the technologies behind hydraulic systems. Recent innovations in Rexroth Cartridge Valves include the integration of smart technology and IoT (Internet of Things) capabilities. This advancement allows for real-time data collection and analysis, enabling operators to monitor system performance and make informed decisions to optimize functionality.

For instance, predictive maintenance is becoming an invaluable part of hydraulic operations. By equipping Rexroth Cartridge Valves with sensors, hydraulic systems can alert operators to potential failures before they occur, significantly reducing unscheduled downtime and maintenance costs. Moreover, smart valves can adjust their function based on operating conditions, ensuring optimal performance under varying loads and speeds.

These innovations not only enhance efficiency but also contribute to energy conservation in hydraulic systems. As industries prioritize sustainability, the capability to monitor and optimize hydraulic systems using advanced technology will likely play a significant role in meeting environmental targets while maintaining operational excellence.

In addition to their core functionalities, the interaction between compressed air systems and hydraulic systems further enhances the utility of Rexroth Cartridge Valves. Compressed air can assist hydraulic systems in various ways, including starting, stopping, or controlling hydraulic actuators and motors. This integration provides greater control and flexibility in applications requiring both power sources.

For example, in automated packaging lines, a combination of compressed air motors and hydraulic systems can greatly improve throughput while maintaining precision. Hydraulic systems can provide the necessary force and control for heavy lifting, while the compressed air systems promote quick actuation and responsiveness. This dual system approach leads to improved production efficiency and reduced operational complexities.

To maximize the lifespan and performance of Rexroth Cartridge Valves, proper maintenance is essential. Regular inspections and maintenance scheduling should be implemented to identify wear and components needing replacement. The following are some key areas to focus on during maintenance:

Combining these practices with the advanced sensor technologies mentioned earlier will offer operators a comprehensive strategy towards effectively managing the health of their hydraulic systems.

Rexroth Cartridge Valves continue to be an industry standard in hydraulic solutions. Their engineering prowess and adaptability make them indispensable in a variety of applications, from industrial machinery to agricultural equipment. As industries advance, the demand for reliable and efficient hydraulic components like Rexroth Cartridge Valves remains pivotal, ensuring optimized performance and sustainability in modern systems.

Looking ahead, the integration of advanced technologies, including smart sensors and predictive maintenance systems, will further increase their relevance in an evolving market. As companies strive to enhance productivity while minimizing their environmental footprint, Rexroth Cartridge Valves will undoubtedly play a significant role in shaping the future of hydraulic systems.

Understanding the intricacies of these valves and their applications will become increasingly critical for engineers and operators alike, ensuring that they are well-prepared to harness the full potential of hydraulic technology in the years to come. With continued innovation and commitment to quality, Rexroth Cartridge Valves will remain at the forefront of hydraulic solutions for an array of industries and applications.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!