This article delves into Rexroth Cartridge Valves, focusing on their role in hydraulic systems. Rexroth, a notable brand under Bosch Rexroth, is renowned for crafting precision-engineered hydraulic components that are pivotal in diverse industrial applications. We explore the design, functionality, and practical insights surrounding these valves.

Rexroth Cartridge Valves are integral components in modern hydraulic systems, showcasing engineering excellence in the fluid technology domain. These valves provide precision and reliability, which are quintessential in high-performance applications. Designed and manufactured by Bosch Rexroth, a leader in the industrial equipment manufacturing sector, these valves reflect a long-standing commitment to innovation and quality. This article delves deeper into the critical functionalities, various applications, and the intricacies associated with Rexroth Cartridge Valves, offering insights drawn from extensive industry expertise.

Hydraulic systems rely heavily on components like Rexroth Cartridge Valves to regulate fluid flow, maintain pressure, and control movement within machinery. These valves are essential for ensuring optimal performance in various applications, from simple lifting mechanisms to complex industrial machinery. The versatility afforded by their design allows for a seamless integration, ensuring that they can adapt to varying operational conditions. Notably, the modular design facilitates easy maintenance and upgrades, allowing operators to modify system behavior without the need for a complete overhaul.

The ability to control various parameters such as pressure, flow rate, and direction of hydraulic fluid makes Rexroth Cartridge Valves indispensable. They play a key role in enhancing the responsiveness of hydraulic circuits, enabling faster cycle times, which is particularly vital in applications requiring high efficiency and precision. Moreover, the effective regulation of flow and pressure contributes to energy savings, further enhancing operational efficiency—an essential aspect in today’s environmentally conscious manufacturing landscape.

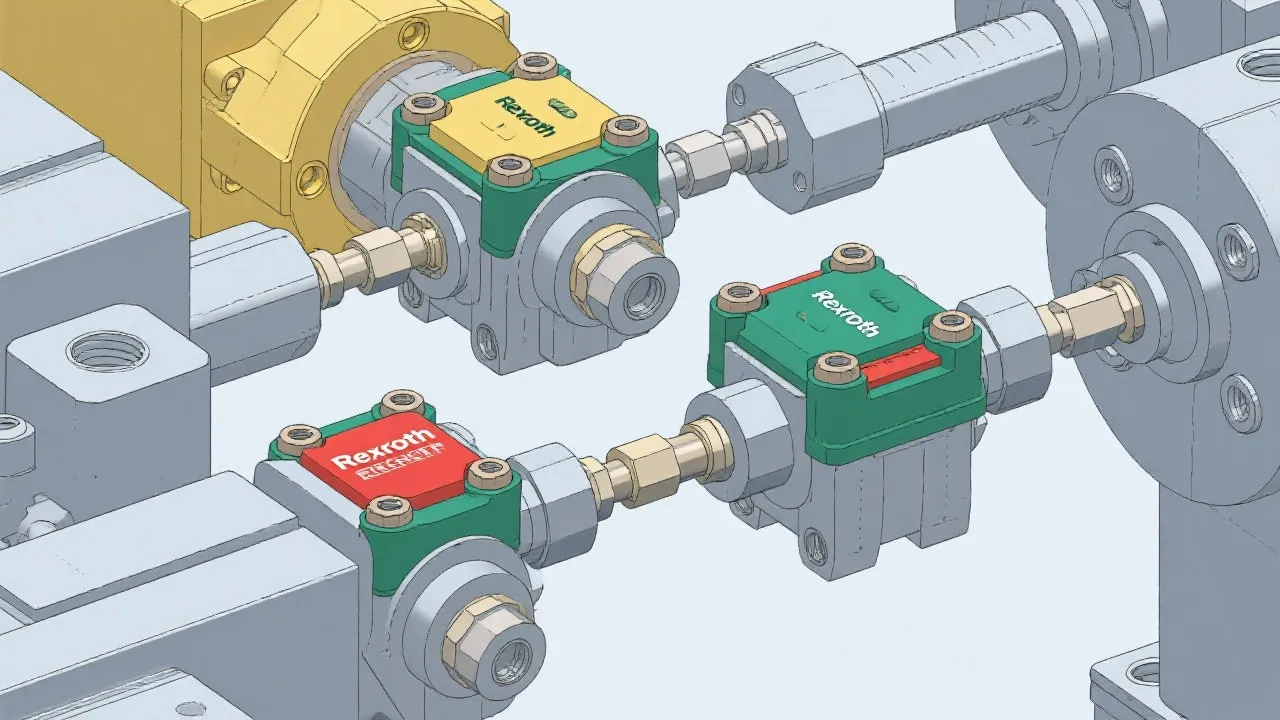

Rexroth provides a vast array of cartridge valves, each designed to cater to specific system requirements. The design of these valves typically features a cartridge housing, spool, and various integral components that work symbiotically to direct fluid flow with precision. The cartridge housing, often made from high-strength materials, encases the spool and other functional components securely, allowing them to withstand the high pressures typical in hydraulic applications. This thoughtful engineering ensures reliability and minimizes the risk of failure, which is critical in field applications.

These valves are engineered to handle high-pressure environments efficiently, ensuring durability and reliability across the board. Bosch Rexroth prioritizes the use of premium materials and advanced manufacturing processes to guarantee that each valve meets stringent industry standards. Standard features include options for sealing configurations, enabling leak-free operation while withstanding extreme environmental conditions such as dust, water, or chemical exposure. Additionally, Rexroth Cartridge Valves are often smaller and lighter than traditional valve assemblies, making them more suitable for modern, compact machine designs.

Rexroth Cartridge Valves are renowned for their unparalleled performance in pressure control and management, leading to increased efficiency and reliability in hydraulic systems. The unique design and high-quality construction of these valves allow them to maintain precise control over fluid dynamics, which is essential in a variety of industries. Sectors such as automotive, aerospace, and heavy machinery utilize these valves extensively to optimize operational efficiency, as they are integral in managing not only the flow of hydraulic fluids but also the overall performance of complex machinery.

Key applications for Rexroth Cartridge Valves include their involvement in specific machinery and processes. For example, in injection molding machines, these valves are crucial for maintaining precise control of fluid injection speed and pressure, directly impacting product quality and cycle times. Similarly, in metal forming equipment, the ability to carefully modulate pressure can lead to enhanced material deformation characteristics, enabling tighter tolerances and improved surface finishes.

In industrial automation systems, Rexroth Cartridge Valves ensure that hydraulic actuators operate with precision and responsiveness, delivering the power needed for tasks ranging from material handling to automated assembly processes. Furthermore, their integration into robotics applications has proven beneficial, enhancing the agility and accuracy of robotic movements. The ability to integrate these valves into multi-functional systems allows manufacturers to streamline operations and reduce the energy consumption associated with hydraulic processes, proving their value in modern industrial applications.

| Feature | Rexroth Cartridge Valves | Generic Cartridge Valves |

|---|---|---|

| Precision | High precision with stringent tolerances | Varies; often less precise |

| Durability | Made from premium materials with robust design | Standard materials; durability varies |

| Compatibility | Wide compatibility with various systems | Limited; may require adaptation |

| Cost | Higher initial investment with good benefits | Lower initial cost with potential higher maintenance |

The comparative analysis above highlights the distinguishing characteristics of Rexroth Cartridge Valves versus generic alternatives. The high precision and durability of Rexroth products often justify their higher initial cost, as they tend to deliver better long-term performance and lower maintenance costs. This characteristic becomes particularly important in mission-critical applications where reliability is paramount. On the other hand, while generic cartridge valves may offer an attractive entry-level price, they may compromise on precision and longevity, resulting in increased downtime and maintenance expenses over time.

Selecting the appropriate Rexroth Cartridge Valve involves a comprehensive assessment of the specific requirements of your hydraulic system. Various factors must be evaluated, including the required pressure range, flow characteristics, and the operational environment. Compatibility with existing systems should also be a key consideration, especially where retrofit projects are involved. Each application has unique demands, and Rexroth's extensive catalog allows for the identification of valves that can meet the specific characteristics necessary for optimal system performance.

It is advisable to consult with a Rexroth distributor or a hydraulic systems expert to provide additional guidance and ensure that the chosen valve aligns with operational criteria effectively. Proper analysis can help prevent issues stemming from incorrect valve selection, such as system inefficiencies or premature wear. The expertise of professionals in the field can provide invaluable insights that contribute to selecting not just the right valve, but the optimal configuration for your entire hydraulic system, thus maximizing efficiency and reliability.

Q: What maintenance do Rexroth Cartridge Valves require?

A: Regular inspections and cleaning are essential to ensure optimal performance. It's advisable to follow the manufacturer's guidelines for service intervals, which typically include checking for leaks, verifying proper operation, and replacing seals or components as needed based on wear and operational hours.

Q: Are Rexroth Cartridge Valves suitable for retrofit projects?

A: Yes, these valves are designed for versatility and can be easily integrated into existing systems. However, an accurate assessment of system compatibility should be conducted before installation. Retrofitting may require additional components or modifications to ensure consistent performance.

Q: How do Rexroth Cartridge Valves contribute to energy efficiency?

A: By maintaining optimal pressure and flow control, these valves minimize energy loss, thereby helping to achieve better efficiency in hydraulic systems. Their precise operation reduces hydraulic losses, which is crucial in applications where energy consumption must be minimized to enhance sustainability.

Q: Can these valves be customized?

A: Bosch Rexroth offers extensive customization options to fit specific industrial requirements. This ensures that each valve aligns seamlessly with customer needs, such as special mounting configurations, specific media compatibility, or unique pressure and flow specifications.

Rexroth Cartridge Valves have evolved significantly, incorporating advanced technologies and innovative features that further enhance their capabilities. Some of the noteworthy advancements include built-in diagnostic capabilities that allow for real-time monitoring of valve performance. This feature enables predictive maintenance, where potential issues can be identified before they result in failure, thus reducing downtime and maintenance costs.

Additionally, the integration of electronic controls into Rexroth Cartridge Valves allows for greater flexibility and precision in system management. With the advent of Industry 4.0, these valves can now be integrated into smart manufacturing environments, where they can communicate with other machines and control systems to optimize workflow and performance. This connectivity enhances the overall responsiveness and adaptability of hydraulic systems, allowing for rapid adjustments in response to changing operational demands.

Furthermore, innovations such as the use of advanced sealing technologies contribute to enhanced longevity and reduced leakage, which is particularly important in environmentally sensitive applications. These advancements represent a significant leap forward in ensuring that hydraulic systems remain not only effective but also compliant with stringent environmental regulations.

As industries worldwide strive to reduce their environmental footprint, Rexroth Cartridge Valves are designed with sustainability in mind. The company implements rigorous testing and adherence to environmental regulations, ensuring that its products operate efficiently and cleanly. The materials used in the construction of these valves are chosen for their longevity and recyclability, which contributes to sustainability goals.

Moreover, the energy efficiency attributed to Rexroth Cartridge Valves not only reduces operational costs but also aligns with global efforts to decrease greenhouse gas emissions. By optimizing hydraulic systems to consume less energy, manufacturers can significantly lower their environmental impact, making these valves a smart choice for forward-thinking companies committed to sustainability.

The availability of eco-friendly options in valve components also enhances compliance with environmental laws. This forward-looking approach is indicative of Bosch Rexroth's commitment to sustainability and innovation in hydraulic technology.

Looking ahead, several trends are emerging in cartridge valve technology that could further revolutionize the industry. One prominent trend is the increasing adoption of hydraulic hybrid systems, which integrate hydraulics with electric drive systems. This hybrid approach allows for substantial energy savings and improved responsiveness, particularly in applications where peaks in power demand present a challenge.

Another trend is the growing demand for multifunctional valves that can provide multiple control functions within a single assembly. This reduces the complexity of hydraulic circuits and can lead to significant space savings within machinery designs. Manufacturers are constantly seeking ways to integrate capabilities such as pressure relief, flow control, and directional control into single valve units, simplifying setups while enhancing performance.

Additionally, advancements in material science will likely lead to the development of lighter, more resistant materials that can withstand extreme conditions while maintaining performance and durability. Such advancements will provide opportunities for even more compact designs that meet the needs of increasingly space-constrained applications.

Finally, as machine learning and artificial intelligence become more ingrained in industrial applications, the role of valves will evolve. Enhanced data analytics could provide insights into valve performance, operational efficiencies, and areas for improvement. Intelligent valves that adapt their operation based on real-time data could lead to unprecedented levels of precision and responsiveness in hydraulic systems, indicating a promising direction for future development.

Rexroth Cartridge Valves stand out within the hydraulic industry due to their superior engineering, versatility, and advancements in technology that meet and exceed the demands of modern applications. Understanding their design and operation is crucial for achieving optimal performance in various industrial contexts, where reliability and efficiency can dictate operational success. As technology continues to advance, these valves are poised to play a pivotal role in shaping the future of hydraulics, aligning with the industry's shift toward sustainability and efficiency.

Ultimately, investing in Rexroth Cartridge Valves represents a prudent choice for industries aiming to enhance system performance, reduce energy consumption, and foster a proactive approach to maintenance. By leveraging the capabilities of modern hydraulic systems, companies can not only achieve greater productivity but also contribute to a more sustainable industrial landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!