Rexroth Cartridge Valves are integral components in hydraulic systems, known for their reliability and precision. Used across various industries, these valves help control fluid flow efficiently. With a reputation for durability and performance, Rexroth continues to innovate in the field of industrial hydraulics, offering solutions that meet diverse operational demands.

The mechanical heart of efficient hydraulic systems, Rexroth Cartridge Valves have established a prominent presence in industries reliant on fluid power. These valves play a significant role in optimizing hydraulic systems, which are crucial for various applications, from construction equipment to automotive machinery. This detailed piece explores their functionality, applications, and the wide-ranging advantages they bring to complex operations, highlighting their importance in modern industrial specifications.

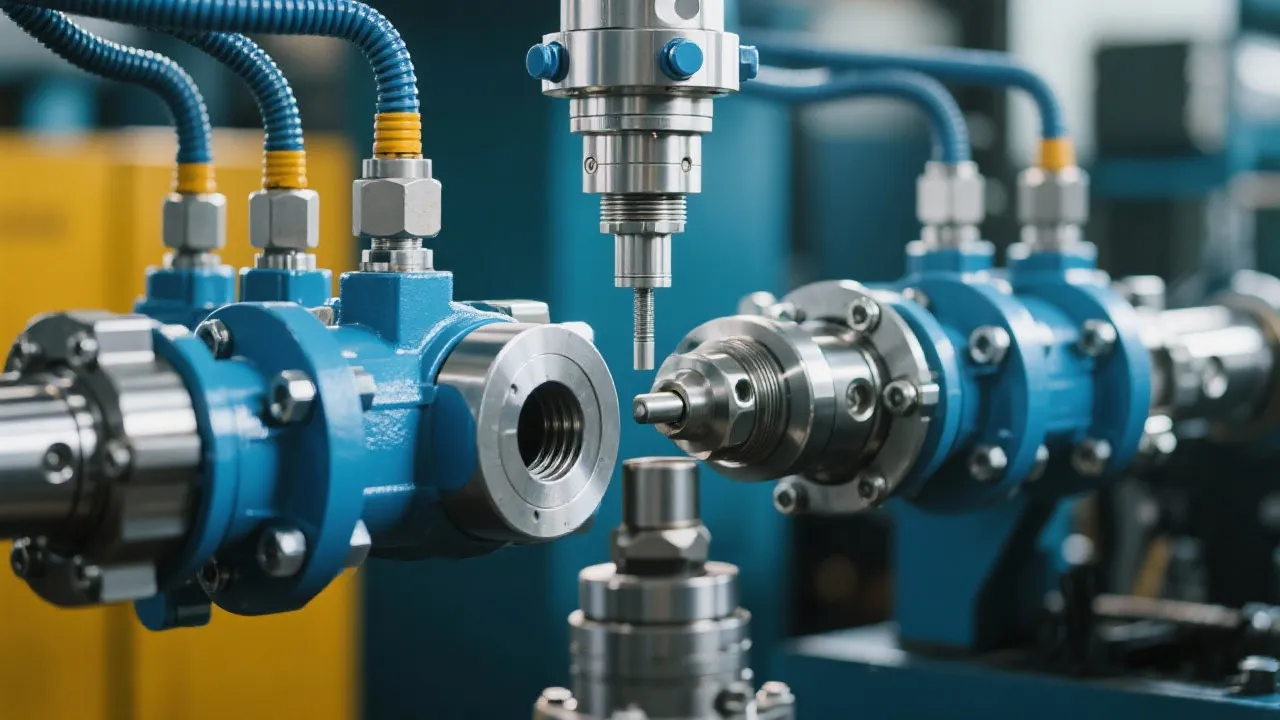

Rexroth Cartridge Valves are designed to control hydraulic fluid, providing precise flow and pressure regulation in a compact form factor. Uniquely engineered, these valves are constructed to handle high pressure and variable flow, making them indispensable in scenarios where exact hydraulic control is paramount. Their design integrates seamlessly with diverse hydraulic circuits, offering flexibility and customization for specific industrial needs. Each valve consists of a body that houses a spool, which moves within its bore to redirect fluid flow. This construction allows for various configurations, including directional control, pressure regulation, and flow control, tailored uniquely to application requirements.

Moreover, the compact nature of cartridge valves allows them to be easily integrated into existing hydraulic systems without requiring extensive modifications. Their modular design simplifies both installation and maintenance, enabling quick replacements without the need for comprehensive system overhauls. The materials used in their construction, such as high-grade steels and advanced composites, contribute to their ability to withstand harsh operating conditions, rendering them suitable for both mobile and stationary applications.

The versatility of Rexroth Cartridge Valves allows their use in numerous sectors. From automotive manufacturing that demands precision in assembly lines to aerospace engineering where reliability is non-negotiable, these valves ensure operational efficiency and maintain strict safety standards. They encapsulate the harmony between durability and functionality, essential for modern production and operational processes.

In the construction industry, for example, hydraulic systems relying on Rexroth Cartridge Valves can effortlessly manage the multitude of functions needed for earth-moving equipment, cranes, and excavators. These machines often operate in extreme environmental conditions; thus, the robustness of Rexroth’s solutions is vital for uninterrupted performance. Similarly, in industrial automation, where robotic systems require fluid power for motion control, the accuracy and reliability of cartridge valves underpin their functionality.

Looking beyond traditional roles, Rexroth Cartridge Valves are also essential in agriculture, where precision hydraulics in planting machinery, harvesters, and irrigation systems contribute to enhancing productivity while minimizing resource waste. Their adaptability allows for one valve to serve multiple functions within complex circuit designs, reducing inventory requirements for manufacturers and end-users alike.

According to industry reports, the demand for sophisticated hydraulic components like Rexroth Cartridge Valves is expected to grow. This growth aligns with advancements in automation and the increasing focus on energy-efficient machinery, which reflect a wider trend towards sustainable industrial practices. As manufacturers aim for greener operations, the integration of intelligent hydraulic systems becomes essential, with Rexroth leading the charge in providing cutting-edge solutions that not only meet but exceed current and anticipated industry standards.

Furthermore, the rise of smart technology in hydraulic systems denotes a significant shift in how processes are managed in various sectors. Intelligent sensors and monitoring devices can provide real-time data, allowing for proactive decision-making and remote control capabilities, enhancing overall system performance. Rexroth Cartridge Valves, with their capability to integrate with such technologies, will undoubtedly play a critical role in this evolving landscape.

| Specification | Rexroth Cartridge Valves | Competitor A |

|---|---|---|

| Maximum Pressure | 350 bar | 300 bar |

| Flow Rate | 50-300 l/min | 40-250 l/min |

| Material | High-grade Steel | Standard Alloy |

| Energy Efficiency | Optimized | Standard |

When evaluating cartridge valves in the context of performance and application, it's essential to consider not only their technical specifications but also how they compare with competitors on various parameters. For instance, Rexroth's hallmark technology often allows for a higher maximum pressure rating at 350 bar, which is advantageous for heavy-duty applications that require robust pressure handling. Additionally, the flow rates reaching up to 300 liters per minute position them favorably for high-throughput operations seen in industrial settings.

Material quality also plays a pivotal role in the longevity and reliability of hydraulic components. By utilizing high-grade steel, Rexroth ensures its valves can withstand harsh conditions, corrosion, and wear, further extending their operational life compared to a competitor using standard alloys. This material choice translates to less frequent replacements and lower lifecycle costs, a significant consideration for businesses focused on operational efficiency.

Moreover, Rexroth's commitment to optimizing energy efficiency aligns well with the current trend towards sustainability. Industries around the globe are increasingly scrutinizing the energy consumption of their operational infrastructure, and Rexroth Cartridge Valves are built to minimize energy losses, thereby not only cutting costs but also diminishing environmental impact.

Q: What is the primary function of Rexroth Cartridge Valves?

A: They primarily control the hydraulic fluid's flow and pressure in a system, ensuring precise operation of machinery crucial in various industrial applications.

Q: How do they contribute to system efficiency?

A: By optimizing energy use and ensuring precise control, Rexroth Cartridge Valves reduce operational costs, extend the lifespan of hydraulic systems, and enhance overall performance.

Q: In which industries are they very commonly used?

A: They are prevalent in automotive, aerospace, construction, manufacturing, agriculture, and many other sectors where hydraulic systems are critical for operations.

Q: What are the maintenance requirements for Rexroth Cartridge Valves?

A: Regular inspection is advisable to monitor for any signs of wear or leakage, but thanks to their durable design, they often require less frequent maintenance compared to traditional valves.

For those interested in furthering their knowledge in hydraulic systems and components, understanding the role of Rexroth Cartridge Valves is fundamental. They not only bolster the intricacies of fluid control but also aid in the enhancement of operational efficiencies, promising a future of advanced automation and economic sustainability in industrial processes. Their adaptability, backed by continuous innovation, places them front and center in shaping the hydraulic landscape.

As industries strive for enhancements in automation and operational efficiency, manufacturers like Rexroth have committed to continual innovations that address changing market demands. Some of these advancements include the integration of smart technologies into cartridge valves. The advent of sensors and data analytics capabilities enables real-time performance monitoring and predictive maintenance, allowing operators to anticipate failures before they occur. This not only maximizes uptime but also extends the lifecycle of the hydraulic components and systems.

Furthermore, advancements in simulation technologies allow for precise modeling of hydraulic systems before implementation. By utilizing computational fluid dynamics (CFD) and finite element analysis (FEA), engineers can design higher-performing cartridge valves that better meet the specific needs of the application. These simulations can also lead to more robust solutions that perform reliably under varying conditions, ultimately providing clients with tailored solutions that enhance productivity.

Emphasis on digitalization reflects a shift towards Industry 4.0, where interconnected devices work in tandem to optimize performance. Rexroth Cartridge Valves equipped with IoT capabilities can communicate with other hydraulic or electronic components to optimize the entire hydraulic system. Such integration supports functionalities like automated pressure and flow adjustments that respond in real-time to changing operational requirements, contributing to enhanced efficiency across the board.

Understanding the practicality of Rexroth Cartridge Valves can best be appreciated through various case studies that illustrate their deployment across industries. Let's consider the automotive manufacturing sector, where these valves have played a transformative role. In one specific automotive assembly line, Rexroth Cartridge Valves were incorporated to manage the hydraulic control of robotic arms involved in precision fastening. The result was a significant increase in production speeds and accuracy, reducing the product assembly time by 25% and minimizing errors through more precise hydraulic control.

In aerospace, reliability is non-negotiable. Rexroth Cartridge Valves were implemented in hydraulic systems on a new generation of aircraft for controlling landing gear and wing flaps. The demanding application required components that could withstand extreme pressures while ensuring fail-safe operation. The direct result of utilizing these high-quality valves was an enhancement in passenger safety and aircraft efficiency, showcasing how performance translates into trust that an aircraft operates under stringent reliability standards.

Additionally, in agriculture, a tractor manufacturer integrated Rexroth Cartridge Valves within their hydraulic lift systems for plows and planters. Utilizing these solutions allowed farmers to control the depth and engagement of their implements with precision, thereby boosting productivity and operational efficiency on the field. Enhanced control not only translates into better crop yields but also contributes to sustainable practices through optimal resource usage, showcasing the versatile benefits of employing these valves.

Rexroth Cartridge Valves stand as a cornerstone in fluid power technology, embodying the essence of reliability and precision that industries depend upon in today’s fast-paced environment. Their innovative design and robustness make them ideal for a multitude of applications, significantly enhancing performance and operational efficiency across various sectors. As industries increasingly move towards automation and sustainable practices, the role of advanced hydraulic components like Rexroth Cartridge Valves will only become more critical.

With a comprehensive understanding of their functionality, specifications, and adaptability, a clearer picture emerges of how Rexroth Cartridge Valves can not only meet current demands but also align with future technological advancements. They facilitate operational improvements not just through their technical capabilities but through the strategic integration into complex systems that respond efficiently to modern industrial challenges.

The future of hydraulic systems lies in these sophisticated components, and with continued investment in research and development, Rexroth Cartridge Valves will remain at the forefront, helping industries realize significant efficiencies and innovations in their operation pipelines.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!