Rexroth Cartridge Valves are essential components in hydraulic systems renowned for their reliability and efficiency. These valves play a crucial role in regulating fluid flow within various industrial applications. Designed for optimal performance, they offer solutions to common hydraulic challenges, ensuring stability and precision in operations.

Rexroth Cartridge Valves play a pivotal role in various hydraulic systems across diverse industries including manufacturing, automotive, aerospace, construction, and agriculture. Renowned for their durability and efficiency, these valves manage the flow and pressure of hydraulic fluids, ensuring precise control over machinery operations. A prominent member of the Bosch Rexroth family, they are supported by cutting-edge engineering, innovative design, and rigorous standards for quality and performance. Understanding their function and application is essential for optimizing hydraulic system performance.

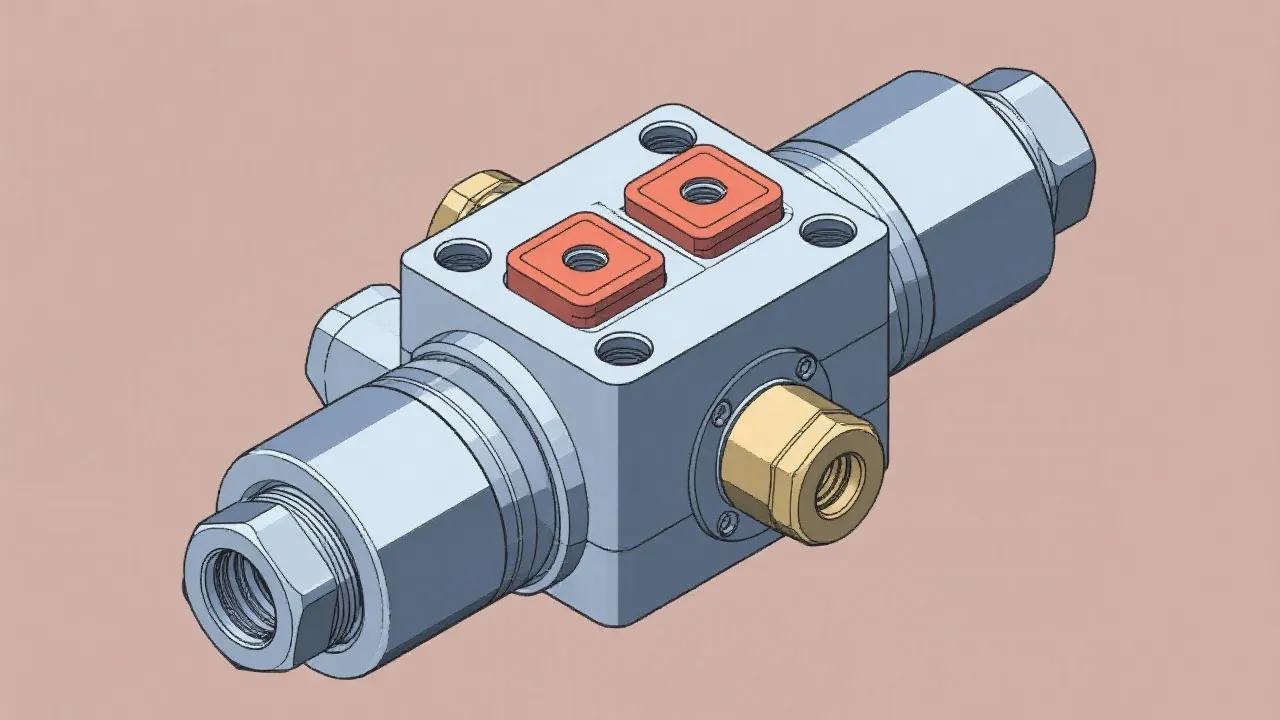

Cartridge valves act as the control points within hydraulic systems. Their primary function is to manage pressure, flow, and direction of hydraulic fluids, with each valve designed to meet specific operational requirements. Rexroth’s cartridge valves are engineered for versatility, accommodating a wide variety of applications across multiple sectors. The modular architecture of these valves allows for easy integration into existing systems, enabling them to be added or replaced with minimal downtime, hence significantly reducing any potential maintenance needs.

Rexroth Cartridge Valves can be categorized into several types, each designed for specific functions within hydraulic systems:

Utilizing Rexroth Cartridge Valves presents several noteworthy advantages, including:

Integrating Rexroth Cartridge Valves into hydraulic systems effectively enhances stability and reliability for fluid control mechanisms. They are well-suited for both retrofits and new installations, providing seamless compatibility with existing setups while ensuring full system functionality. The high precision and responsiveness of these valves lead to improved operational efficiency, reduced energy consumption, and superior performance in delivering the desired hydraulic outcomes.

Moreover, the adaptability of Rexroth’s cartridge valves allows manufacturers and engineers to design systems that maximally utilize available space while still achieving the necessary flow and pressure conditions. The capacity to integrate with modern control systems further augments their utility, allowing for advanced control strategies and automation.

Selecting the appropriate Rexroth Cartridge Valve necessitates a comprehensive understanding of the unique demands of your hydraulic system. Important considerations include:

Proper installation is crucial for maximizing the lifespan and operational capabilities of the valves. It is highly advisable to consult with a Rexroth-certified engineer or technician to conduct thorough assessments and ensure that optimal integration is achieved. This professional guidance can prove invaluable in avoiding common pitfalls during installation, particularly when integrating into complex systems.

| Type | Application | Benefits |

|---|---|---|

| Pressure Control | Maintaining system pressure | Prevents system overpressure, ensures safety and reliability of operations |

| Flow Control | Regulating flow rate | Improves efficiency and precision, enables synchronization of movement in machinery |

| Directional Control | Determining fluid path | Controls various movements of machinery, enhances precision and responsiveness |

Rexroth Cartridge Valves find their application in a multitude of industries due to their unique adaptability and performance reliability. Here are a few examples:

In manufacturing, Rexroth cartridge valves are used extensively in hydraulic presses, injection molding, and assembly lines. Their ability to manage precise movements and regular pressure helps ensure consistent product quality and efficiency in production processes. The valves facilitate automation, vital for modern manufacturing settings where decreased cycle times and increased production speeds are critical.

Automotive manufacturing and assembly lines depend on the functionality of hydraulic systems that utilize Rexroth cartridge valves for tasks such as stamping, welding, and lifting components. These valves enable effective control over the hydraulic actuators applied during assembly processes, enhancing precision and operational safety. Furthermore, their rugged design allows for operation in environments with hydraulic fluid contamination.

In the aerospace sector, Rexroth cartridge valves are essential for ensuring the reliability of components within hydraulic braking systems and flight control systems. The high demand for safety and precision in aerospace applications makes the reliability of these valves paramount. Their ability to perform in high pressure and extreme conditions ensures that they can handle the rigorous demands of modern flying machines.

In sectors like construction and agriculture, Rexroth cartridge valves are integral to the operation of heavy machinery, such as excavators, bulldozers, and agricultural implements. These valves manage the functions of hydraulic cylinders and motors, allowing for efficient movement and operation of machinery in tough conditions. Their robustness offers assurance of longevity and effective operation, even under substantial loads and harsh environmental stressors.

The robotics industry leverages Rexroth cartridge valves in various applications where precision hydraulic control is necessary. Their adaptability in automated systems allows for accurate motion control and the ability to respond to feedback loops in real time, producing highly efficient and reliable automation solutions. The modular nature of these valves also facilitates easy upgrades and adjustments as technologies advance.

Working with cartridge valves can pose certain challenges, from installation difficulties to operational issues. Awareness and proper preparation can help mitigate these challenges effectively:

Improper installation is one of the chief causes of malfunctions in cartridge valves, leading to issues such as leaks and system failures. Ensuring proper alignment, torque preservation, and cleanliness during installation can significantly decrease the likelihood of these challenges. Utilizing the right tools and following recommended installation procedures will further enhance installation quality.

Hydraulic systems may experience performance issues due to factors like fluid contamination, which can lead to premature wear or failure of cartridge valves. Regular monitoring and maintenance, including fluid filtration and replacement, are crucial to ensure the longevity of the valves. In addition, implementing comprehensive maintenance protocols will help recognize and resolve potential problems before they occur.

In older systems, compatibility challenges may arise when integrating new Rexroth cartridge valves with legacy components. It is critical to assess compatibility with existing hydraulic elements, including hoses, pumps, and fittings. In such cases, creating a complete system diagram that documents all hydraulic components can help identify areas needing upgrades or replacements to ensure seamless compatibility and performance.

The future of Rexroth cartridge valves is closely tied to innovation and advancements in hydraulic technology. Some emerging trends include:

As industries continue to move towards automation, the integration of smart technology into hydraulic systems will be crucial. Cartridge valves are expected to play an integral role in automated and intelligent systems, enabling real-time data analytics and responsive operational adjustments.

The demand for sustainability is driving the development of more energy-efficient hydraulic solutions. Advances in cartridge valve designs aim to reduce energy consumption while maintaining or enhancing performance. These innovations will include more precise flow control and the utilization of alternative hydraulic fluids.

The Internet of Things (IoT) is making substantial inroads into manufacturing and machine operation. Future cartridge valves may feature embedded sensors that collect data on performance metrics, allowing for predictive maintenance and automated adjustments. This integration can lead to significantly reduced downtime and optimized operational efficiency.

As material science progresses, the use of advanced materials with higher resistance to wear, corrosion, and extreme temperatures in cartridge valve manufacturing will help extend the lifespan and reliability of these components, enhancing performance capabilities in challenging environments.

Rexroth Cartridge Valves represent an essential component in the management of hydraulic systems across various industries. Their reliability, efficiency, and adaptability not only enhance the performance of hydraulic systems but also contribute to the overall safety and innovation within diverse applications. Understanding their functionality, benefits, and integration strategy is crucial for engineers and technicians working with hydraulic systems to ensure optimal operation. As technology progresses, the future holds promising potential for further enhancements in cartridge valve technology, which will undoubtedly shape the operational landscape of hydraulic applications in years to come.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!