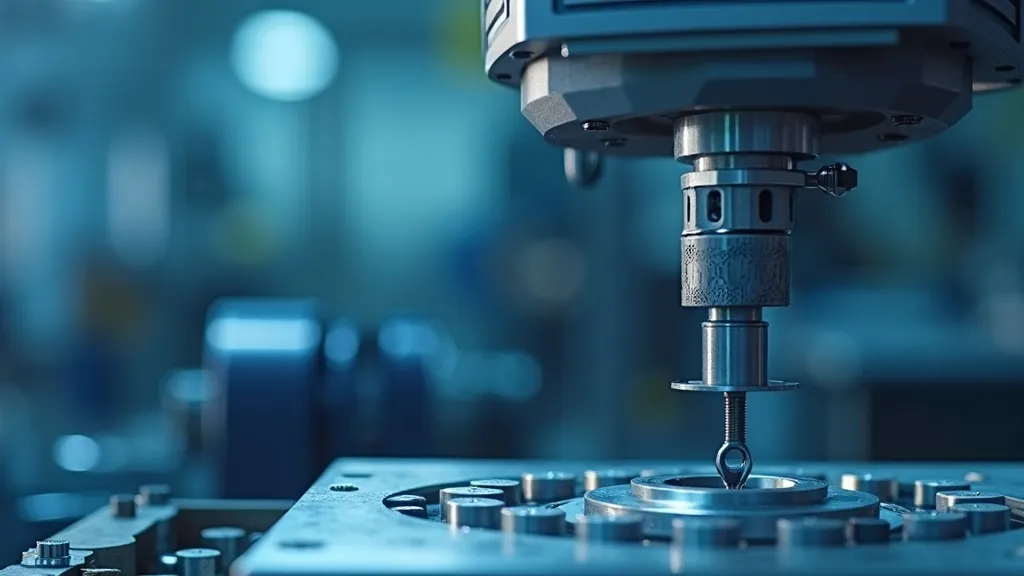

CNC adjusters are essential components in the precision field of machine tools and automation. These adjusters help in fine-tuning machines for optimal performance, ensuring the smooth operation of CNC (Computer Numerical Control) systems. By improving the efficiency and precision of manufacturing processes, CNC adjusters play a significant role in industries ranging from automotive to aerospace.

In the realm of modern manufacturing, CNC adjusters stand as pivotal elements that contribute significantly to the functioning of CNC machines. These components are engineered to provide precision adjustments, critical for maintaining the accuracy and efficiency of automated systems. Understanding their role, types, and maintenance can lead to enhanced operational efficacy in various manufacturing sectors, ultimately impacting the quality, speed, and cost-effectiveness of production lines.

CNC adjusters are integral to ensuring that the machine components are aligned correctly and operate under optimal conditions. Their primary function involves making precise changes to machine settings, which is crucial for tasks that require a high level of accuracy and repeatability. Whether it's in the automotive industry, aerospace engineering, or electronics manufacturing, the accuracy provided by CNC adjusters can significantly influence the quality of the final product.

By allowing operators to fine-tune the values that control machining processes, CNC adjusters enable the production of parts that meet stringent tolerances and specifications required by industries such as aerospace, automotive, and medical devices. For instance, an aerospace component might need to meet specifications within microns, and without the help of CNC adjusters, achieving such precision would be exceedingly difficult.

Moreover, CNC adjusters contribute to reducing the time taken to make changes between production runs. In environments where products need to be customized or changed frequently, having reliable and adjustable settings can enhance overall production flow, making it possible to pivot swiftly from one task to another.

There are various types of CNC adjusters available, each tailored for specific roles:

The implementation of CNC adjusters offers several advantages to manufacturing processes:

To keep CNC adjusters functioning at their prime, regular maintenance is crucial. Follow these guidelines for optimal performance:

1. What industries primarily use CNC adjusters?

CNC adjusters are widely used within the automotive, aerospace, electronics, and general manufacturing sectors. Each of these industries relies on the precision machining capabilities provided by CNC technology, where adjusters play a crucial role in ensuring the integrity of the processes.

2. How do CNC adjusters improve machining accuracy?

They allow for precise control and alignment of machine components, ensuring that all operations conform to their desired specifications. Without accurate adjustments, the potential for misalignment increases significantly, which can lead to defects and reduced product quality.

3. What regular maintenance do CNC adjusters require?

Regular inspections, lubrication, software updates, and calibration checks are essential for maintaining CNC adjusters in optimal working condition. Additionally, operators should monitor performance data to catch any deviations early.

As technology evolves, so too do CNC adjusters. The advent of Industry 4.0 has introduced new automation and digital technologies that enhance the capabilities of CNC systems. The integration of IoT (Internet of Things) with CNC adjusters allows for real-time data transfer, further optimizing performance and maintenance schedules.

With advancements in AI and machine learning, CNC adjusters can learn from historical data, making predictive adjustments that enhance efficiency and minimize downtime. Predictive analytics forecasts potential errors and maintenance needs before they arise, allowing manufacturers to be more proactive rather than reactive.

Emerging technologies in additive manufacturing and hybrid machining processes also affect CNC adjuster design and functionality, leading to more specialized and adaptable components that can accommodate a wider variety of materials and techniques. This means that CNC machines equipped with advanced adjusters can handle complex parts that were previously considered too challenging or costly to manufacture.

Understanding the crucial role of CNC adjusters can be deepened through examining real-world applications in different sectors:

The automotive industry often requires extreme precision in manufacturing components such as engine parts and transmission systems. For example, a leading automotive manufacturer employed CNC adjusters to optimize the production of engine components used in high-performance vehicles. By implementing advanced linear and rotary adjusters, they improved their tolerance ranges from ±0.5 mm to ±0.1 mm. This change resulted in significant reductions in production errors and rework costs.

Aerospace components, which must adhere to the highest safety and quality standards, benefit immensely from CNC adjusters. A notable aerospace company adopted advanced angular adjusters for the fabrication of turbine blades. These blades require very specific arc angles for optimal performance. With the integration of digital adjusters that automatically calculated the required angles based on the material specifications, the company not only enhanced production efficiency but also improved the longevity of the blades, leading to a safer and more reliable product.

With the rise of miniaturization in electronics, the precision of PCB (Printed Circuit Board) manufacturing has become paramount. A leading electronics manufacturer utilized tiny linear adjusters in their CNC machines to achieve the precise alignment necessary for soldering tiny components. This advancement dramatically reduced the waste produced during production, allowing the company to cut costs while increasing reliability in the performance of their electronic devices.

The future of CNC adjusters lies in further innovations that blend smart technology and manufacturing processes. Future trends include:

In conclusion, CNC adjusters play an indispensable role in the precision and efficiency of CNC machines. Their application within the manufacturing landscape ensures products meet exacting standards, fostering innovations and advances across various industries. As we look to the future, the continued evolution of CNC adjusters, driven by technological advancements and changing industry needs, will further bolster their importance in promoting productivity and quality in manufacturing. Emphasizing the ongoing education and training of personnel who operate and maintain these systems will be essential in harnessing their full potential in the dynamic landscape of modern manufacturing.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!