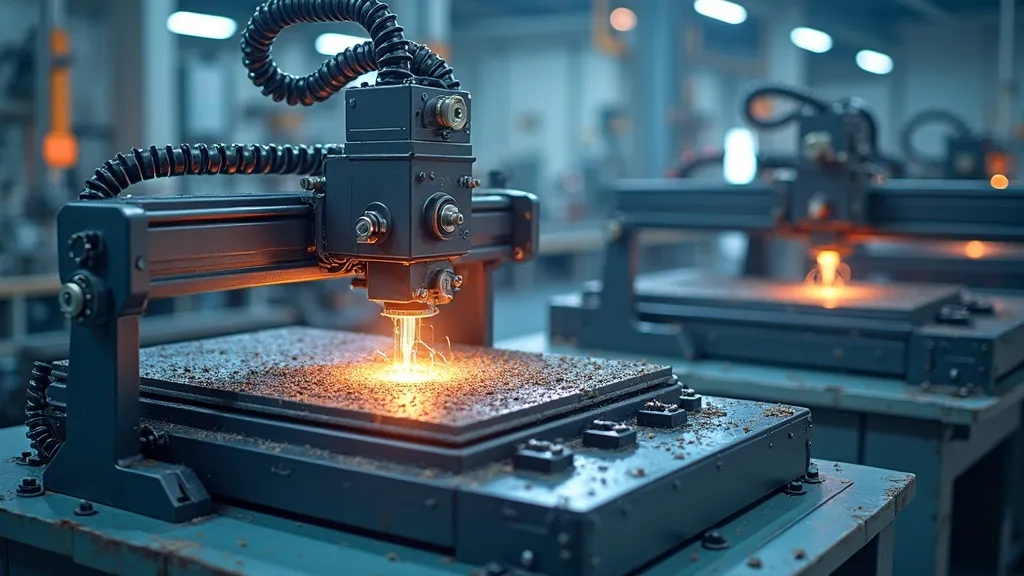

CNC adjusters play a critical role in precision manufacturing, overseeing the calibration and optimal functioning of CNC machines. This article delves into the importance of CNC adjusters, exploring their skills, impact on production efficiency, and insights from industry practices. It provides a comprehensive understanding of CNC adjusters' roles within the context of modern manufacturing systems.

In the fast-paced and highly technological realm of manufacturing, CNC adjusters are indispensable. These skilled professionals ensure the efficacious operation of Computer Numerical Control (CNC) machines, which are pivotal in machining components across industries. CNC machines revolutionize how parts are designed, prototyped, and manufactured, underscoring the adjusters’ role in maintaining precision and efficiency. CNC technology itself adheres to incredibly meticulous guidelines, which demand the expertise of CNC adjusters to ensure that the machinery operates within those specifications. Over time, as the demand for precision manufacturing has grown, the role of the CNC adjuster has become increasingly specialized, necessitating deeper knowledge in various disciplines, including mechanics, electronics, and computer programming.

CNC adjusters primarily focus on calibrating machines, adjusting settings, and ensuring that outputs meet precise specifications. Their expertise reduces production errors and scrap rates, ultimately enhancing productivity. Their role requires an understanding of both mechanical aspects and programming, merging technical prowess with a keen eye for detail to maintain the stringent quality standards demanded by today's industries. Additionally, CNC adjusters often play an important role in troubleshooting during the production process. When issues arise—such as a deviation in part dimensions or machine malfunctions—they must be quick to diagnose root causes and implement solutions. This instantaneous problem-solving capability can significantly reduce production delays and minimize cost overruns.

Improvements in CNC adjusters' methodologies have substantially impacted manufacturing productivity. As manufacturing becomes increasingly complex and customized, the pressure on CNC adjusters has heightened. Their ability to swiftly adapt to new machine models and programming languages ensures that production lines operate seamlessly, preventing costly downtimes and maintaining output quality. This aspect is particularly critical in industries that require high-stakes precision, such as aerospace or medical device manufacturing, where tolerances are significantly tighter than in conventional manufacturing contexts. Furthermore, effective CNC adjusting often involves collaborating closely with engineers and designers. By providing feedback from the operating floor, they help develop more efficient designs that consider the limitations and capabilities of the machining technology.

Successful CNC adjusters possess a blend of technical skills and analytical abilities. Proficiency in programming, a robust understanding of machine operations, and problem-solving capabilities are essential. They often engage in continuous learning to keep up with advancements in CNC technologies and methodologies. Machine tools are constantly evolving with new features aimed at enhancing productivity and quality; thus, a CNC adjuster’s ability to adapt and learn about these advancements can make a significant difference in workflow efficiency and output quality.

| Key Skill | Importance |

|---|---|

| Technical Expertise | Understanding machine operation and troubleshooting. This includes knowledge of mechanical systems, hydraulics, and electronics. |

| Programming Skills | Writing and debugging CNC machine code. Familiarity with various programming languages, such as G-code and M-code, is paramount. |

| Analytical Skills | Diagnosing issues and optimizing machine performance. Analyzing specific machine functions, including feed rate and cutting depth, can greatly enhance production efficiency. |

| Attention to Detail | Ensuring precision and accuracy in outputs. A small deviation can lead to significant issues or product failures, particularly in critical applications. |

| Continuous Learning | Keeping up with technological advancements. Regular training and professional development are essential for staying relevant in a fast-evolving field. |

The world of CNC adjusting is not static; it has undergone profound changes due to advancements in technology and production methods. Initially, machine operators utilized manual methods for adjustments, often relying heavily on mechanical gauges and visual inspections. Over time, as digital technologies emerged, CNC machines began to integrate computer systems for more automated handling of tasks. This shift required CNC adjusters to not only understand mechanical operations but also to become proficient in programming and using advanced software. Today, CNC adjusters often leverage simulations and predictive analytics that provide insight into potential machine failures before they occur, allowing for preventative maintenance that saves time and resources.

Modern CNC adjusters benefit significantly from innovative tools and technologies designed to streamline their tasks. One such advancement is the implementation of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, which allows for more precise design and machining of parts. These tools enable adjusters to visualize components in a three-dimensional space, increasing accuracy in diagnostics and programming. Furthermore, advancements such as IoT (Internet of Things) have paved the way for smart CNC machines equipped with sensors that collect and relay real-time data about machine performance. This technology empowers CNC adjusters to make data-driven adjustments and continuously optimize processes.

CNC adjusters typically work in manufacturing facilities and machine shops where they interact closely with other professionals, such as machinists, engineers, and production managers. This collaborative environment promotes the exchange of ideas and innovations that can lead to improved production processes and efficiencies. Communication is a crucial skill for CNC adjusters, as they often need to convey technical information to non-technical stakeholders. This may involve explaining the implications of various machine settings or addressing concerns about production timelines associated with machinery performance.

To equip themselves for the challenges of this high-tech role, many CNC adjusters pursue formal education and training. Vocational schools and community colleges frequently offer programs specifically designed for CNC machining and programming. Additionally, certification from professional organizations, such as the National Institute for Metalworking Skills (NIMS), can enhance an adjuster's qualifications, showcasing their competence to prospective employers. Continuous education opportunities, workshops, and seminars further aid in refining skills and keeping up with the latest technologies.

CNC adjusters face a variety of challenges in their line of work. Rapid technological advancements can make it difficult to keep skills up to date, potentially leading to knowledge gaps among the workforce. Moreover, high expectations for efficiency and precision put pressure on adjusters to minimize machine downtime and product defects, often leading to a stressful work environment. Changes in production schedules, unexpected machine breakdowns, and the complexities of programming new machinery can also present formidable challenges. Additionally, as the demand for advanced manufacturing techniques grows, adjusters may need to adapt to various industry-specific requirements, such as compliance with stringent safety standards or specialized machining methods.

Looking to the future, the role of CNC adjusters is expected to evolve even further as manufacturing practices become more automated and integrated with smart technologies. The rise of Industry 4.0—characterized by automation, data exchange, and advanced manufacturing—will likely change how CNC adjusters carry out their responsibilities. They may find themselves placing greater emphasis on data analysis and interpretation, utilizing machine learning algorithms to preemptively address potential machine failures and optimize production schedules. Furthermore, as additive manufacturing methods (like 3D printing) gain traction, CNC adjusters may need to expand their skillsets to include these technologies, further demonstrating the necessity of adaptability in the industry.

The multifaceted nature of CNC adjusting increasingly requires professionals to possess interdisciplinary skills. Beyond technical expertise in machines and programming, adjusters benefit from foundational knowledge in fields such as materials science, physics, and engineering principles. Understanding the properties of different materials being machined, along with their behavior under various conditions, can empower adjusters to make informed decisions that optimize both machine performance and product quality. For example, familiarity with the thermal expansion of materials during machining can help prevent dimensional inaccuracies, ensuring that components meet design specifications.

CNC adjusters remain integral to the landscape of modern manufacturing. They embody a critical intersection of technology, precision, and craftsmanship, driving industries forward. As manufacturing technologies advance, the role of CNC adjusters will continue to evolve, promising further enhancements in production capabilities and quality standards, thus retaining their status as vital components in industrial success. Their adaptability and innovative mindset will not only support current manufacturing objectives but will also lay the groundwork for future developments in the industry. It is this ongoing evolution—towards smarter, more interconnected manufacturing environments—that ensures the continuing relevance of CNC adjusters in an increasingly automated world.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!