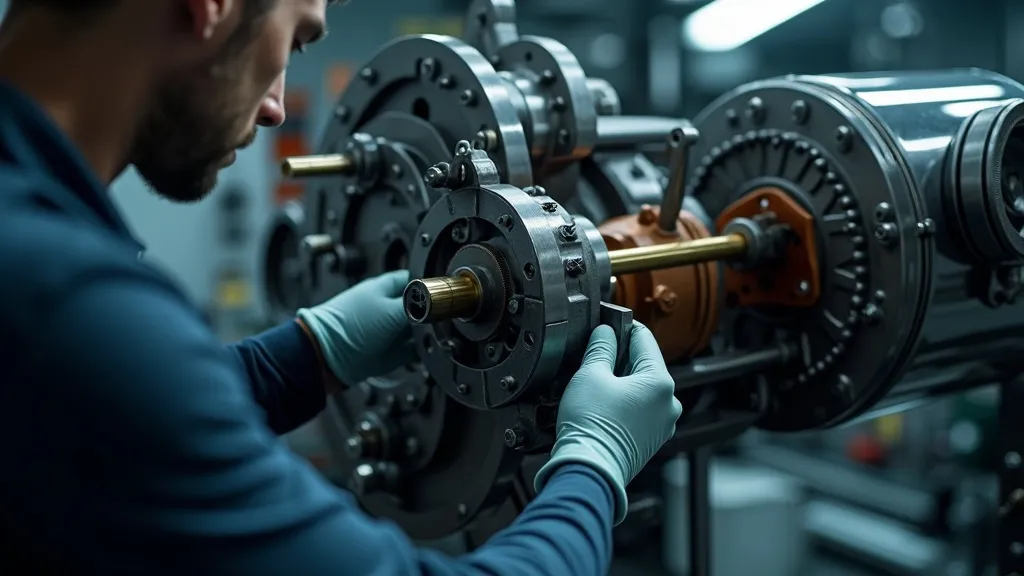

CNC Adjusters play a vital role in the precision and functionality of CNC machines. These components ensure that computer numerical control systems operate with accuracy and efficiency, vital to industries like automotive and aerospace. This exploration delves into the importance, function, and latest advancements in CNC adjusters, illuminating their critical role in maintaining industrial productivity.

Computer Numerical Control (CNC) machines have revolutionized manufacturing by providing precise control over the production process. At the heart of their accuracy and efficiency are CNC adjusters, essential components that maintain the alignment and calibration of CNC machinery. These adjusters are utilized to enhance the performance of the machines, minimizing production errors while maximizing output. The evolution of CNC technology has fundamentally transformed industries, enabling the mass production of complex parts with an unmatched level of detail and repeatability.

CNC adjusters are crucial for ensuring the machines operate within set parameters. They help in maintaining the correct alignment of machine parts, which is vital for producing exact specifications. This precision is particularly important in industries like aerospace and automotive, where minute discrepancies can lead to significant performance issues. CNC adjusters not only enhance the accuracy of the machine operations but also play a critical role in maintaining the longevity of the equipment. By enabling constant adjustments according to production demands, these devices contribute to the stability of the entire manufacturing process.

Additionally, effective use of CNC adjusters reduces material wastage by ensuring that each cut or manufactured piece meets precise standards. This capability is particularly advantageous in environments where costs are closely monitored and quality control is non-negotiable. In short, the role of CNC adjusters extends beyond mere functionality; they embody the precision craftsmanship that modern manufacturing is built upon.

Recent advancements in CNC technology have led to the development of more sophisticated adjusters. These new models offer enhanced precision and are capable of making real-time adjustments based on feedback from the machine, improving both the quality and speed of production. The incorporation of advanced materials and innovative design principles in CNC adjusters marks a significant leap forward in manufacturing technology.

| Advancement | Description |

|---|---|

| Real-Time Adjustment | Adjusters that automatically correct positioning errors as they occur, improving accuracy and minimizing error propagation throughout the production line. |

| Enhanced Durability | Using advanced materials that withstand extreme conditions, including temperature fluctuations and high-stress environments, increasing the lifespan of adjusters. |

| Integration with IoT | IoT-enabled adjusters that provide seamless connectivity and data analysis capabilities, enabling predictive maintenance and remote monitoring. |

Moreover, with the emergence of Industry 4.0, CNC adjusters are increasingly integrating with cloud computing and data analytics. This integration enables manufacturers to collect vast amounts of operational data, which can be analyzed to identify trends and insights. The predictive algorithms can forewarn operators about potential adjustments required based on historical performance, reducing unplanned downtimes.

While advancements have made CNC adjusters more efficient and reliable, challenges remain. Some of these include the initial cost of technology upgrades, which can be a significant barrier for smaller manufacturers. Implementing cutting-edge CNC adjusters often requires substantial investment not only in the equipment itself but also in the infrastructure needed to support its operation.

Furthermore, the requirement for specialized training for operators is another hurdle that organizations must overcome. As technology becomes increasingly complex, operators must develop a deeper understanding of both the machinery and the software that drives it. Companies may need to invest in ongoing training programs to ensure that their workforce remains competent in utilizing advanced CNC adjusters effectively.

Another challenge is the necessity for continuous maintenance and troubleshooting. CNC adjusters, like all mechanical components, are subject to wear and tear, necessitating regular checks and maintenance schedules. Without these proactive measures, minor issues can escalate, leading to significant downtime and production delays. Hence, developing a robust maintenance strategy is crucial for businesses that depend on CNC technology for their operations. These challenges highlight the need for careful planning and resource allocation when integrating advanced CNC adjusters into existing manufacturing processes.

To illustrate the impact that CNC adjusters can have within the manufacturing sector, consider the following case studies from diverse industries.

A major aerospace manufacturer implemented IoT-enabled CNC adjusters in their milling machines, leading to dramatic improvements in production efficiency. Prior to this upgrade, operators often relied on manual adjustments, resulting in frequent delays and inaccuracies. The new CNC adjusters allowed for real-time monitoring of machine performance and immediate rectification of misalignments.

As a result, the company reported a 30% reduction in production time for complex aircraft components. More importantly, the accuracy of parts increased significantly, leading to a reduced number of rejections during quality control inspections. The cost savings and increased output solidified the business's position in a competitive market.

An automotive parts manufacturer faced challenges with high rates of scrap and rework due to alignment issues with their CNC laser cutting machines. By integrating enhanced durability CNC adjusters, they minimized the incidence of misalignment and maintained consistent production quality.

After implementing the new adjusters, the manufacturer noted a 20% decrease in material waste and a corresponding increase in profitability. This case demonstrates the potential ROI when investing in advanced CNC technology. In addition to financial benefits, improved customer satisfaction and higher product reliability solidified the manufacturer's reputation in the marketplace.

A precision engineering firm specializing in custom components for medical devices adopted real-time adjustment CNC technology to improve their manufacturing process. The company caters to a niche market where precision is paramount; even the slightest deviation could compromise the safety and effectiveness of medical equipment.

By leveraging CNC adjusters that allow for automatic recalibration, the firm achieved an unprecedented level of precision, yielding a significant decrease in human error. The outcome was not only fewer defects, but also increased trust from their clients, leading to expanded contracts and new partnerships.

Looking ahead, several trends are poised to shape the future of CNC adjusters and their integration into manufacturing workflows. One notable trend is the increasing deployment of artificial intelligence (AI) within CNC systems. AI algorithms can analyze operational data and suggest optimal adjustment settings, effectively taking the guesswork out of the calibration process. This capability will enhance precision and streamline production even further.

Another trend is the growing focus on sustainability in manufacturing practices. CNC adjusters designed with eco-friendly materials and energy-efficient designs will likely become more prevalent as companies strive to lower their environmental impact. Using CNC technology not only contributes to resource conservation through minimized waste but can also improve energy efficiency during manufacturing processes.

Furthermore, the rise of augmented reality (AR) in training and maintenance operations offers a unique opportunity for CNC adjusters. Operators can utilize AR applications to visualize machine adjustments and settings in real-time, significantly lowering the training curve and enhancing overall operational efficiency.

Q: What are CNC adjusters?

A: CNC adjusters are devices used to maintain the calibration and alignment of CNC machines, ensuring they operate with precision. They are essential components of CNC machinery that contribute to the overall accuracy and efficiency of production processes.

Q: Why are CNC adjusters important?

A: They are essential for maintaining the high precision output of CNC machines, which is crucial in industries that require high accuracy, such as automotive and aerospace. CNC adjusters ensure that machine parts are aligned correctly, minimizing errors and scrap rates, and ultimately enhancing productivity.

Q: What are the latest advancements in CNC adjusters?

A: Advancements include real-time adjustment capabilities, increased durability, and integration with IoT for improved connectivity. Additionally, the use of AI and machine learning will enhance predictive maintenance, allowing for adjustments before issues occur.

Q: What challenges exist in using CNC adjusters?

A: Challenges include high initial costs, the need for specialized training, the requirement for ongoing maintenance, and the complexity of new technologies which might necessitate significant shifts in operational strategy.

As manufacturing technology continues to evolve, the role of CNC adjusters becomes even more critical. These devices ensure that CNC machines operate at peak efficiency, a necessity in today's high-speed, high-precision industrial environment. By embracing advancements and overcoming challenges, industries can maximize the benefits of CNC technology. Looking forward, the integration of AI and sustainable practices, along with continuous training, will undoubtedly set the stage for further innovations in CNC adjuster technologies, leading to a future where precision, efficiency, and sustainability go hand in hand.

The ongoing focus on these advancements will not only enhance production capabilities but will also ensure that the manufacturing industry meets the challenges of tomorrow, characterized by greater complexity and a need for rapid response to ever-changing market demands. Thus, CNC adjusters will remain at the forefront of this industrial evolution, continuing to shape the landscape of precision manufacturing.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!