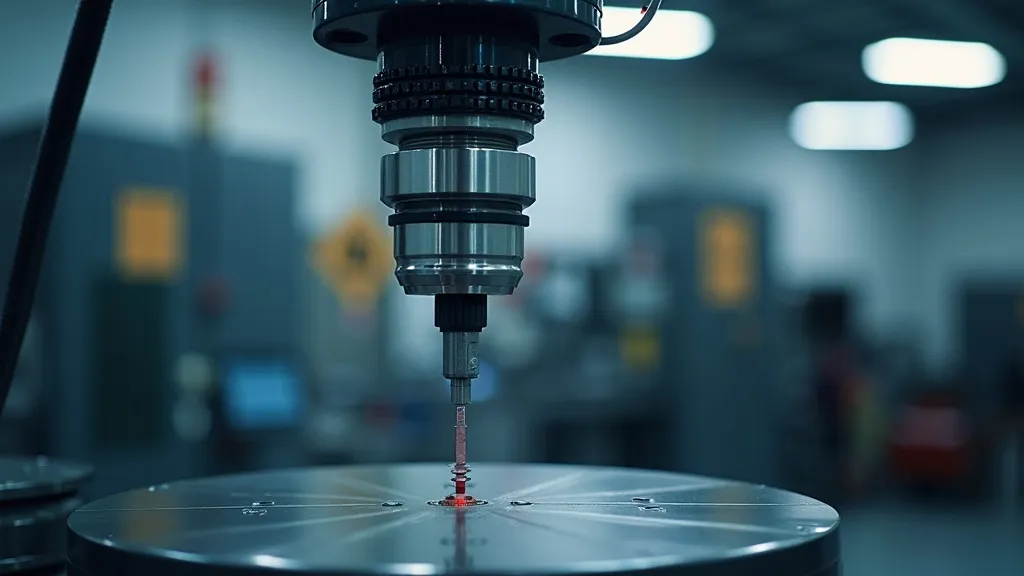

CNC Adjusters are pivotal components in the manufacturing industry, ensuring precision and efficiency in CNC machine operations. Exploring the intricacies of these adjusters reveals their critical role in optimizing performance, reducing downtimes, and maintaining the integrity of machining processes. This article investigates the operational mechanisms and benefits of CNC Adjusters in modern manufacturing.

The precision and efficiency of CNC (Computer Numerical Control) machines are vital in today's manufacturing industry. At the core of this precision are CNC Adjusters. These devices ensure that CNC machines operate with the highest level of accuracy, reducing waste and streamlining production processes. In the dynamic landscape of manufacturing, where demands for quality and speed are at an all-time high, the role of CNC Adjusters continues to evolve, becoming increasingly pivotal in maintaining production excellence.

Understanding CNC Adjusters means recognizing their impact on the output quality of CNC machines. They help maintain dimensional tolerances, which is crucial for products requiring high standards of precision, like aerospace components or medical devices. The slightest deviation can result in significant costs, product recalls, and can even jeopardize safety in industries such as automotive and healthcare.

CNC Adjusters work by fine-tuning various aspects of a machine's operation. Factors like alignment, calibration, and movement are adjusted to enhance the machine's overall performance. Regular adjustments ensure that machines always operate at peak efficiency, minimizing errors and the need for rework. One of the very significant benefits of using CNC Adjusters is the reduction of downtime. Machines that are frequently adjusted can run longer without breakdowns, significantly increasing productivity in manufacturing settings. This shift to proactive adjustment strategies helps manufacturers realize not just operational excellence but also substantial cost savings.

The importance of CNC Adjusters can also be seen in specific machining applications. For example, in the automotive industry, where the specifications for components such as gearboxes and crankshafts are incredibly tight, the role of CNC Adjusters in ensuring the machines produce components that consistently meet these specifications cannot be overstated. This level of precision allows manufacturers to innovate and improve their products continually while maintaining compliance with rigorous industry standards.

The growing reliance on CNC technology in manufacturing has increased the demand for expert knowledge and tools for maintaining machinery performance. CNC Adjusters are seen not only as essential tools but as strategic investments for companies seeking to boost competitiveness and operational efficiency. Industry observers note that firms that prioritize the upkeep of their CNC systems, including adjustments, are more likely to experience less variation in product quality, leading to enhanced customer satisfaction and trust.

Moreover, the impact of CNC Adjusters extends beyond their immediate function. They serve as a critical component in the overall strategy for digital transformation, which is central to Industry 4.0. In this context, understanding how adjustments influence the lifecycle and performance of CNC machines positions businesses to adopt predictive maintenance approaches, reducing unexpected failures and optimizing the supply chain.

Industry experts highlight that regular and precise adjustments lead to reduced operational costs. The insights from professional technicians emphasize the importance of routine checks and calibrations, often delivered as part of comprehensive maintenance plans. Knowledgeable technicians are critical in understanding both the mechanistic and electronic components of the machines, allowing for accurate adjustments that can significantly reduce the incidence of production errors, enhance machine longevity, and ultimately lead to more consistent output quality.

Furthermore, advancements in technology have led to the development of increasingly sophisticated CNC Adjusters. These include features such as real-time feedback mechanisms, which allow operators to observe machine performance and make adjustments dynamically. This level of connectivity and responsiveness is becoming a standard expectation in modern manufacturing environments, driven by the need for speed and agility in product delivery.

Advanced CNC systems are often equipped with automated adjustment capabilities, which might mark the future of CNC Adjusters. In contrast, current systems require skilled technicians who understand the nuances of each machine. This integration implies a profound knowledge of both software and hardware adjustments to meet manufacturing demands. The ability to program CNC Adjusters to respond automatically to tool wear and environmental changes enhances operational efficiency further, leading to reduced waste and improved production rates.

This shift towards integration is also influencing training and education within the industry. Technicians are now expected to possess a broader skill set that encompasses not only mechanical abilities but also programming and data analysis skills. As a result, manufacturers investing in their workforce will find that they are better positioned to leverage advanced CNC Adjusters, ultimately translating into competitively-priced high-quality products.

As technology progresses, the landscape of CNC Adjusters is expected to undergo significant changes. Emerging trends suggest that the future will see even greater levels of automation integrated into CNC systems, rendering traditional adjustment techniques partially obsolete. The Internet of Things (IoT) will play a critical role, allowing machines to communicate with some central control system that oversees numerous indicators of machine performance and wear. This predictive approach to maintenance and adjustments will enable organizations to schedule repairs or tune-ups before a machine fails, further minimizing downtime and enhancing productivity.

Moreover, the use of artificial intelligence (AI) is likely to reshape how adjustments are performed. Intelligent systems could learn from historical data and usage patterns to suggest or automatically perform adjustments that optimize machine performance. For example, if a certain machine consistently produces parts that are slightly out of tolerance, an AI-driven system could adjust operational parameters in real-time based on accumulated data, preventing the issue from reoccurring in future production runs.

The integration of virtual reality (VR) and augmented reality (AR) might also revolutionize the training of technicians dealing with CNC Adjusters. Trainees could benefit from immersive simulations that replicate the experience of making adjustments in a controlled environment. This not only accelerates learning but also builds confidence among technicians before they work on actual machines. Enhanced training protocols driven by VR and AR could lead to a workforce that is more adept at quick adjustments, ultimately fostering a culture of quality and precision throughout the manufacturing environment.

The economic implications of investing in CNC Adjusters can be profound. For companies that incorporate robust adjustment systems into their operational framework, they often see a ripple effect that touches various parts of their business model. Improved production efficiency can translate directly into cost savings, allowing for reduced manufacturing waste and lower operational costs. These savings provide businesses with the flexibility to allocate resources toward innovation, further enhancing competitiveness.

In many industries, the quality of products is paramount. For manufacturers producing highly regulated items, such as pharmaceuticals or aerospace components, the costs associated with errors can be staggering. Recalls, fines, and loss of market reputation can be detrimental. Properly adjusted CNC machines ensure that the outgoing products meet stringent regulatory requirements, which in turn protects against these significant financial risks.

In summary, as manufacturing processes become increasingly dependent on precision technology, understanding and utilizing CNC Adjusters becomes vital. Not only do they enhance production efficiency, but they also uphold the superior quality of outputs, making them indispensable in any modern manufacturing setup. The ability to adapt to rapid technological advancements while maintaining rigorous standards for quality is key to thriving in the competitive manufacturing landscape.

Manufacturers are encouraged to regularly invest in both technology upgrades and workforce training to ensure they can maximize the capabilities of their CNC Adjusters, thereby improving their overall competitive stance in the market. Through the incorporation of advanced technology, proactive maintenance strategies, and enhanced training protocols, businesses can position themselves as leaders in an industry that is increasingly defined by precision, efficiency, and innovation.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!