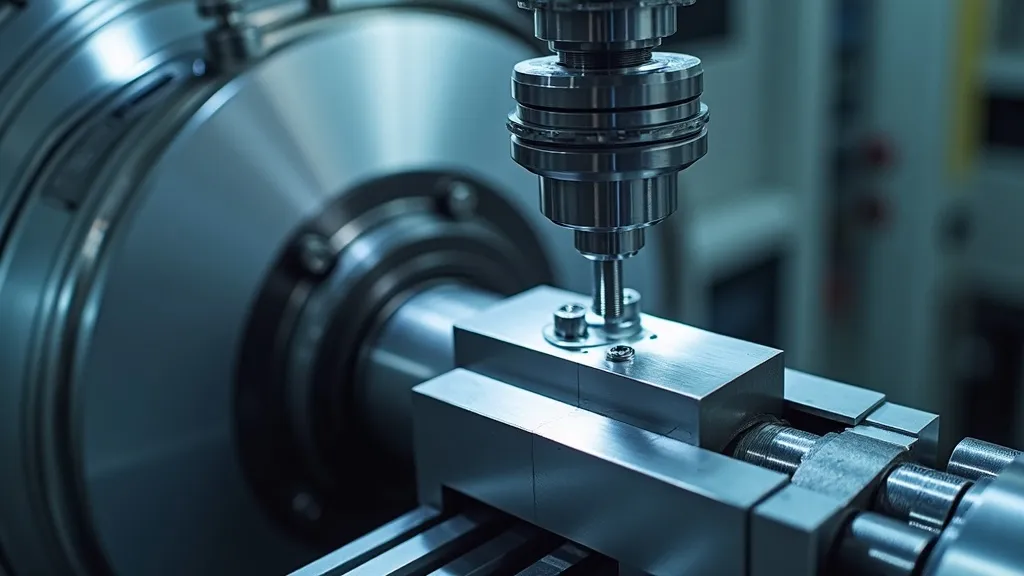

CNC adjusters are pivotal in ensuring precision in manufacturing processes. As industries increasingly integrate advanced computer numerical control systems, adept adjusters are necessary to manage, calibrate, and maintain these sophisticated machines to maximize productivity and consistency. This article delves into the crucial functions, industry standards, and future trends surrounding CNC adjusters.

CNC adjusters are essential in the landscape of modern manufacturing, ensuring the seamless operation of precision machinery. As the backbone of automated production environments, these professionals fine-tune CNC machines, which are integral for producing complex parts with flawless accuracy. This article explores the crucial role of CNC adjusters, industry expectations, and the future pathway of this indispensable profession. Efficient manufacturing is increasingly dependent on these skilled experts who balance technological proficiency with hands-on experience. In an era where precision manufacturing is paramount, understanding CNC adjusters' responsibilities, skills, and future potential is vital for anyone looking to thrive in the manufacturing sector.

CNC adjusters are tasked with calibrating and maintaining CNC machinery to assure accuracy in product specifications. Their duties often include interpreting blueprints, selecting appropriate tools, and making precise adjustments to machines. Regular monitoring and troubleshooting are critical responsibilities, ensuring that machinery operates at optimal efficiency while meeting quality standards. Not only are they involved in the setup and operation of CNC machines, but they are also pivotal in diagnosing technical issues that may arise, thereby preventing costly downtimes. Furthermore, CNC adjusters must keep detailed logs of their adjustments and maintenance activities, which provides valuable data for process improvement and machine reliability.

To effectively carry out their roles, CNC adjusters must possess a combination of technical skills and soft skills. Attention to detail is imperative as precision is critical in manufacturing components that meet exact specifications. Additionally, communication skills are essential; CNC adjusters often work in teams with engineers, operators, and production managers to ensure that everyone is aligned on the requirements of the project at hand. These adjusters must also be comfortable providing training and support to less experienced staff, sharing their knowledge to enhance overall operational efficiency.

The role of CNC adjusters is governed by stringent industry standards to guarantee both the safety and productivity of manufacturing operations. Compliance with ISO certifications and adherence to company-specific guidelines are mandatory. Moreover, CNC adjusters need to stay abreast of rapidly evolving technologies and procedures as the machinery they work with becomes increasingly sophisticated. Continuous learning and adaptation are the norms, with certifications often required to validate expertise in the latest CNC technologies. It is important for CNC adjusters to be familiar with relevant safety protocols, environmental regulations, and quality control measures specific to their sector.

Industry standards also emphasize the importance of quality management systems and process control strategies; these frameworks help CNC adjusters implement systematic approaches to achieve high-quality outcomes. By employing methodologies such as Six Sigma or Lean manufacturing principles, CNC adjusters can contribute to substantial waste reduction and efficiency improvements, which are critical in a climate where market competitiveness hinges upon consistent product quality and operational cost-effectiveness.

CNC adjusters often find that basic machine operation knowledge will only take them so far. Advanced methodologies involve understanding the interplay of various production variables and implementing machine learning algorithms to predict maintenance needs. Embracing these advanced techniques can significantly increase a plant's throughput and minimize errors that compromise product integrity. CNC adjusters frequently collaborate with engineers to hover above the baseline calibration and engage in processes like precision fault analysis and machine diagnostics.

Among advanced techniques, CMMS (Computerized Maintenance Management System) software enables CNC adjusters to schedule maintenance more effectively, manage inventory needs for parts and tools, and analyze data to identify patterns in machine performance. Moreover, embracing predictive maintenance techniques, which leverage data analytics to foresee equipment failures before they occur, enhances the reliability of manufacturing processes. This approach not only saves companies substantial costs associated with machine downtime but also increases overall production output.

Another significant advancement in CNC adjusting is the integration of augmented reality (AR) and virtual reality (VR) technologies. These innovations can allow CNC adjusters to visualize complex machinery setups and troubleshooting scenarios, thereby enhancing their ability to quickly and accurately respond to issues. Training programs that utilize AR and VR create immersive learning experiences for new adjusters, enabling them to master operations safely and effectively before ever engaging with the actual machinery.

As technology propels forward, CNC adjusters will inevitably find themselves adapting to a rapidly changing landscape. The advent of smart manufacturing, a blend of IoT technology and automation, means adjusters must become adept at handling interconnected systems. Upskilling in digital technologies and an understanding of AI-driven analytics will become critical for contemporary CNC adjusters. The demand for proficient adjusters is set to escalate as industries like aerospace, automotive, and electronics push towards precision-driven processes. The role will evolve, but the core necessity for accuracy and maintenance remains timeless.

Moreover, the integration of Industry 4.0 technologies presents additional opportunities for CNC adjusters to shape the manufacturing landscape. Concepts such as digital twins—virtual replicas of physical machines or systems—allow for simulations that predict performance outcomes under varying conditions, empowering adjusters with data-driven insights. Participating in strategic planning processes, CNC adjusters can help drive innovation by providing feedback on machine capabilities and limitations, ensuring that new technologies align with practical operational needs.

Furthermore, CNC adjusters will likely also play a pivotal role in implementing sustainable practices within manufacturing operations. With growing environmental concerns and regulations, there is a strong push for industries to reduce energy consumption and waste. CNC adjusters can spearhead initiatives aimed at optimizing processes to be more eco-friendly, such as applying energy-efficient machining techniques or exploring alternative biodegradable materials for production.

| Aspect | Traditional CNC Adjusters | Modern CNC Adjusters |

|---|---|---|

| Tools Used | Manual tools, basic computing | Advanced software, IoT devices |

| Technical Knowledge | Basic mechanical skills | Advanced digital and mechanical skills |

| Industry Impact | Manual precision | Automated efficiency |

| Data Utilization | Limited data use | Data-driven decision making |

| Training Methods | Hands-on workshops | AR/VR simulations & certifications |

Typically, a CNC adjuster needs a technical degree or certification in CNC machine operations. Experience in a machine shop environment is highly valued, along with a robust understanding of machinery and design blueprints. Some employers may also look for additional qualifications, such as coursework in programmable logic controllers (PLC) and knowledge of CAD/CAM software.

CNC adjusters are paramount to maintaining the precision and reliability of the manufacturing process, ensuring that products meet perceptive client specifications and industry standards consistently. By minimizing machine downtimes and optimizing production processes, they significantly contribute to a company’s efficiency and profitability. They enable manufacturers to deliver high-quality products within tighter timelines, which is essential for staying competitive in today’s fast-paced market.

Yes, the demand for CNC adjusters is ascending due to increased automation in manufacturing processes. With advancements in technology, the need for skilled adjusters who can manage sophisticated machinery is ever more critical, ensuring seamless production aligns with technological advancements. Industries are expanding their workforce to include specialists capable of interfacing traditional practices with new technologies, further solidifying the role of CNC adjusters.

Aside from technical acumen, valuable skills for a CNC adjuster include analytical thinking, problem-solving abilities, and proficiency in technical communication. Familiarity with programming languages for CNC machines, understanding of robotics, and mechanical troubleshooting are also highly desirable. Mastery of mathematical concepts related to machining processes enables adjusters to compute measurements accurately, enhancing the overall quality of produced parts.

CNC adjusters are integral to the backbone of modern manufacturing, their expertise ensuring high precision and efficiency in production lines. Their role will continue to evolve with technology, demanding continuous learning and adaptation. As industries keep advancing towards automation, the CNC adjuster's expertise is indispensable, marking a profound influence on industrial success and innovation. In conclusion, investing in the skill development of CNC adjusters and their adoption of new technologies will ultimately drive the future of the manufacturing sector, ensuring sustained growth and success in an increasingly automated world.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!