This guide explores the intricacies of LVDT proportional valves, integral components in precision flow control. Originating from advanced linear variable differential transformer technology, these valves enable smooth regulation across various industrial applications. Understanding their function, benefits, and applications offers significant insights for engineering and manufacturing sectors aiming to enhance process efficiency and control.

LVDT proportional valves leverage the precision of Linear Variable Differential Transformer (LVDT) technology to manage and regulate flow within various systems crucially. These valves represent a sophisticated solution in industries requiring fine-tuned control over fluid dynamics, allowing for seamless transition and accuracy. In today's fast-paced manufacturing and processing environments, the need for reliability and precision in valve control is paramount. The integration of LVDT technology into proportional valves provides not only standard solutions but enhances overall operational efficiency through sophisticated feedback mechanisms and control systems.

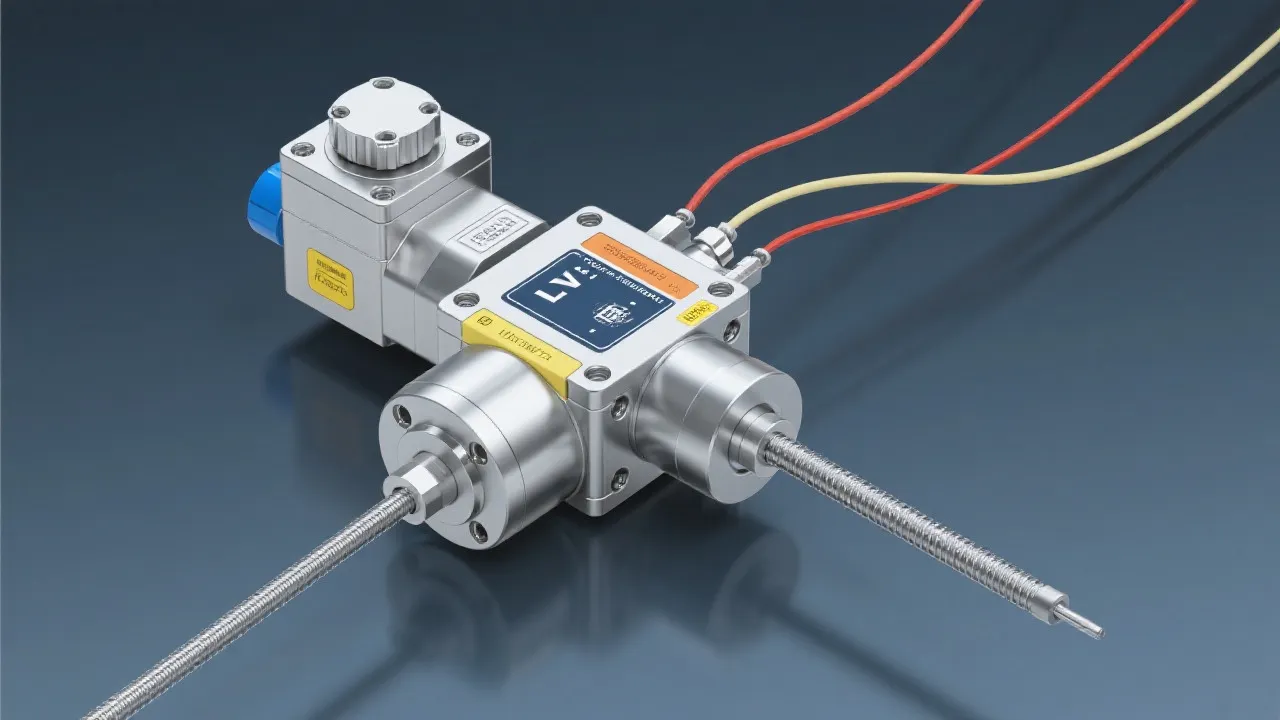

The LVDT is an electromechanical device designed for measuring linear displacement. It functions as the sensor component within the valve, translating mechanical movements into electrical signals that translate into proportional control over valve position. The result is a reliable and repeatable system capable of achieving minute adjustments with minimal lag. This precision is achieved through a three-coil design in the LVDT: a primary coil and two secondary coils arranged symmetrically. When an input voltage is applied to the primary coil, it generates a magnetic field that induces a voltage in the secondary coils. The position of the movable ferromagnetic core, which changes with valve movement, determines the balance of the induced voltages, thus allowing for precise positional feedback.

Industries ranging from aerospace and automotive to chemical processing and agriculture implement LVDT proportional valves. Their primary role is to maintain consistent pressure and flow rate, which are vital in operations where precision dictates quality and safety. In the aerospace sector, for example, LVDT valves play a critical role in hydraulic systems used for controlling flight surfaces and landing gear, where precise actuation is necessary. In automotive applications, these valves can be found in advanced fuel delivery systems and electronic stability controls, providing the necessary flow consistency to optimize vehicle performance. In the chemical processing industry, the accuracy of flow regulation impacts the quality of the produced materials, while in agriculture, LVDT proportional valves assist in refining irrigation processes, thereby maximizing crop yields while conserving water resources.

Manufacturers often provide detailed technical specifications to guide integration and ensure compatibility with existing systems. Understanding these specifications is essential for ensuring optimal operation and performance in specific applications. Key considerations include:

| Component | Description |

|---|---|

| Sensing Core | Provides precise displacement measurements crucial for accurate control. The sensing core is designed to withstand various pressures and is made from durable materials to ensure longevity. |

| Electronics Module | Converts mechanical inputs into actionable electrical signals. Modern electronics modules often include integrated signal processing capabilities for enhanced accuracy. |

| Calibration Software | Ensures the system's accuracy by adjusting readings to match expected parameters. This software can often be updated, enabling continuous improvements in performance monitoring and predictive maintenance. |

Emerging technologies such as AI and IoT are set to redefine how LVDT valves integrate within broader control systems. Real-time data analytics and predictive maintenance capabilities are enhancing operational efficiency, allowing industries to achieve greater productivity with lesser manual oversight. As industries evolve, the integration of smart technologies will play a pivotal role. Virtually connected LVDT valves can monitor their conditions, provide diagnostics, and suggest optimizations to users, creating a feedback loop that promotes both innovation and efficiency. Furthermore, advancements in materials engineering promise further enhancements in valve longevity and resilience. By utilizing advanced materials resistant to wear, corrosion, and thermal shock, manufacturers can produce valves that maintain performance across a wider range of conditions.

To fully appreciate the impact of LVDT proportional valves, consider the following real-world case studies across various sectors:

In aerospace, an established aircraft manufacturer faced challenges with their hydraulic systems controlling wing flaps. The existing valve systems were incapable of providing the necessary responsiveness during critical phases of flight. After implementing LVDT proportional valves, the company experienced a marked increase in control precision, enabling faster actuation of the wing flaps. This change not only improved aircraft performance but also contributed to a safer flying experience, demonstrating how precision in valve control is indispensable in aviation.

In the automotive industry, a leading electric vehicle manufacturer sought to enhance the efficiency of their fuel delivery systems. Conventional valves were reactive rather than proactive, often failing to adjust fuel delivery rates in real time in response to changing operating conditions. By integrating LVDT proportional valves, the company achieved instantaneous response to throttle input, markedly improving engine efficiency and performance while reducing emissions. This case highlights how implementing advanced LVDT technology can lead to significant advancements in vehicle technology.

A global chemical processing plant faced issues with flow accuracy in its mixing operations, leading to inconsistencies in product quality. The management opted to replace existing valves with LVDT proportional valves to enhance precision. The result was a drastic reduction in material waste and an increase in product homogeneity. As a bonus, the plant reported lower operational costs and improved compliance with regulatory standards, showcasing the potential for LVDT valves to transform production processes in compliance-heavy industries.

While LVDT proportional valves offer several benefits, organizations must also navigate certain challenges before widespread implementation. One key consideration is the initial cost of upgrading to LVDT systems, which can be higher than maintaining traditional valves. Therefore, businesses should perform a thorough cost-benefit analysis, factoring in long-term benefits such as reduced maintenance and increased efficiency. Additionally, ensuring compatibility with existing systems without significant retrofitting may require careful planning and consultation with manufacturers.

In conclusion, LVDT proportional valves are integral to modern industrial applications requiring precision and reliability. Their ability to maintain a delicate balance of flow and pressure can significantly influence product quality and operational safety across various sectors. As industries continue to evolve and integrate more advanced technologies, the role of LVDT proportional valves will likely expand and adapt, driving innovations and efficiencies that were previously unattainable. Manufacturers must remain vigilant in assessing the performance and functionality of their valve systems, considering emerging technologies and evolving market demands to remain competitive. By leveraging cutting-edge technology and robust engineering principles, LVDT proportional valves provide an invaluable solution to modern industrial challenges. As industries continue evolving, these systems' precision and adaptability will increasingly define advanced operations worldwide.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!