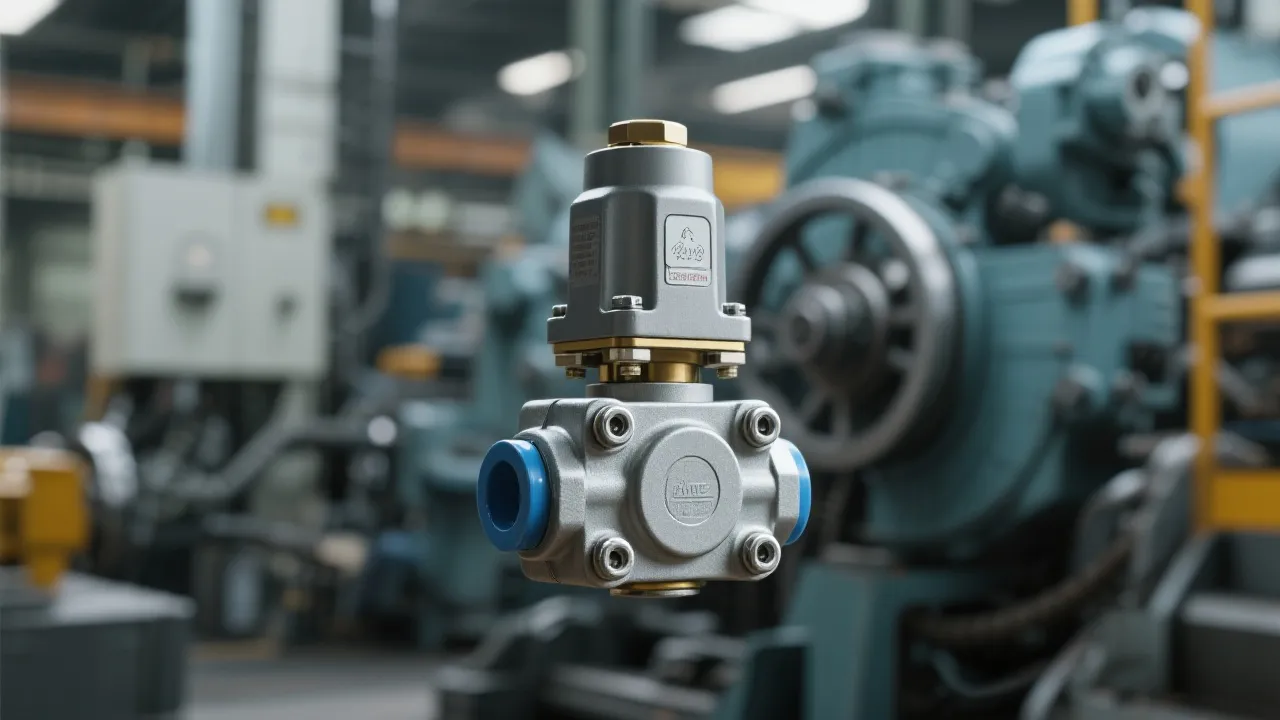

Proportional valves are pivotal in controlling fluid flow and pressure in industrial systems. Commonly used for enhancing precision in manufacturing processes, these valves have become indispensable. This article delves into the mechanics of proportional valves, their applications, benefits, and how they compare to traditional valves in efficiency and performance.

In modern industrial systems, the role of precision in controlling fluid flow and pressure cannot be overstated. Proportional valves have emerged as critical components in this realm, offering the capability to provide fine control over fluid dynamics. These devices are extensively utilized across various sectors, from automotive to manufacturing, playing a key role in optimizing the efficiency and accuracy of operational processes.

Understanding proportional valves involves grasping the fundamental principles of how they operate and their applications across diverse industries. As technologies evolve, the need for enhanced precision and responsiveness in controlling fluid systems becomes critical, further propelling the adoption of these valves. Over the course of this article, we will delve deeper into the mechanics, benefits, and applications of proportional valves, establishing why they are considered essential in any sophisticated industrial setup.

The fundamental working principle of a proportional valve revolves around its capacity to adjust the output flow or pressure progressively relative to the input control signal it receives. Unlike traditional on/off solenoid valves, which only offer binary control (fully open or fully closed), proportional valves can modulate the degree of opening. This enables a variable output, which can be crucial for applications requiring nuanced regulation of fluids.

Proportional valves typically use a feedback loop and a sophisticated control mechanism to ensure that the output closely follows the desired setpoint. This mechanism often involves an electronic controller that interprets sensor signals—such as pressure, flow rate, or position—and adjusts the valve's opening accordingly. The feedback messages from these sensors allow the valve to self-correct in real time, maintaining the desired output even as conditions change.

There are several types of proportional valves, including proportional pressure relief valves, proportional flow control valves, and proportional directional control valves. Each type plays a specific role in a hydraulic or pneumatic system:

Each of these valve types serves unique needs while also sharing the common advantage of variable control. The choice of which type to implement depends on the specific requirements of the system in which it is used.

The versatility of proportional valves allows them to be employed in a myriad of applications. Industries that heavily rely on hydraulic systems, such as aerospace, automotive, and robotics, often utilize these valves to achieve precise motion control and stability. Additionally, the adaptability of proportional valves makes them suitable for managing pneumatic systems, thereby extending their usability to a broader range of industrial processes.

Several advantages underscore the growing preference for proportional valves in industrial settings:

| Type of Valve | Functionality | Efficiency | Applications |

|---|---|---|---|

| Traditional Solenoid Valve | Open/Close | Lower | Basic fluid control, mechanical systems |

| Proportional Valve | Variable control | Higher | Precision fluid control, automation systems |

While traditional solenoid valves serve their purpose, particularly in simpler, less dynamic applications, the enhanced functionality of proportional valves makes them more suitable for advanced industrial uses. For example, in scenarios involving robotics and automation, where complex movements and precise control are essential, proportional valves are vastly superior. They not only ensure that each actuator moves in conjunction with each other but also allow for smooth transitions in motion, thus enhancing the overall performance of the robotic system.

To fully grasp how proportional valves function, it is essential to examine their key components. Understanding these elements provides insight into both their operation and the reason for their advantages over traditional valve types:

The integration of these components results in a system that is both responsive and reliable, capable of handling complex fluid dynamics in real-time applications.

Different industries benefit from proportional valves in unique ways, showcasing their versatility across applications:

These industry-specific benefits illustrate not only the wide range of applications for proportional valves but also their importance in maintaining operational performance and reliability across different environments.

The proper installation and maintenance of proportional valves are paramount to ensuring optimal performance. Installation involves several steps, including the selection of appropriate mounting positions to ensure efficient fluid dynamics, as well as adequate electrical connections for the electronic components.

When installing proportional valves, technicians must consider the following factors:

Regular maintenance plays an equally critical role in ensuring that proportional valves remain functional and reliable. Maintenance routines may involve:

Proper installation and maintenance ensure that proportional valves operate at peak efficiency, which in turn increases the overall reliability and lifespan of the entire system they are part of.

The field of proportional valve technology is continually evolving, driven by advancements in materials, electronics, and control systems. The future promises newer, more efficient solutions that enable even higher precision controls. Key trends shaping the future of proportional valves include:

These trends indicate a bright future for proportional valve technology, with expectations that they will become increasingly integral to advanced industrial systems as they move toward greater automation and complexity.

In the context of contemporary industrial applications, the necessity for control and precision has placed proportional valves as indispensable components across various sectors. Their ability to provide refined control over fluid dynamics not only enhances operational efficiency but also contributes to energy conservation and system longevity. As industries continue to evolve and demand higher precision, the adoption of proportional valves is likely to increase, fostering enhanced performance and sustainability within industrial systems.

Through this exploration of proportional valves, we can appreciate their mechanical innards and multifaceted applications. Whether used in aerospace, automotive, or advanced manufacturing, their contributions towards precision, efficiency, and enhanced control resonate across countless sectors. It is this confluence of technology and industrial need that drives the ongoing development and integration of proportional valves into our increasingly automated world.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!